In the rapidly evolving landscape of the manufacturing industry, the role of machined steel parts has never been more critical. As we approach 2025, industry experts are closely monitoring key trends that are set to transform production processes and elevate operational efficiencies. John Smith, a renowned expert in the field of machining, emphasizes the significance of these shifts, stating, "The evolution of machined steel parts is redefining how manufacturers approach design, durability, and performance."

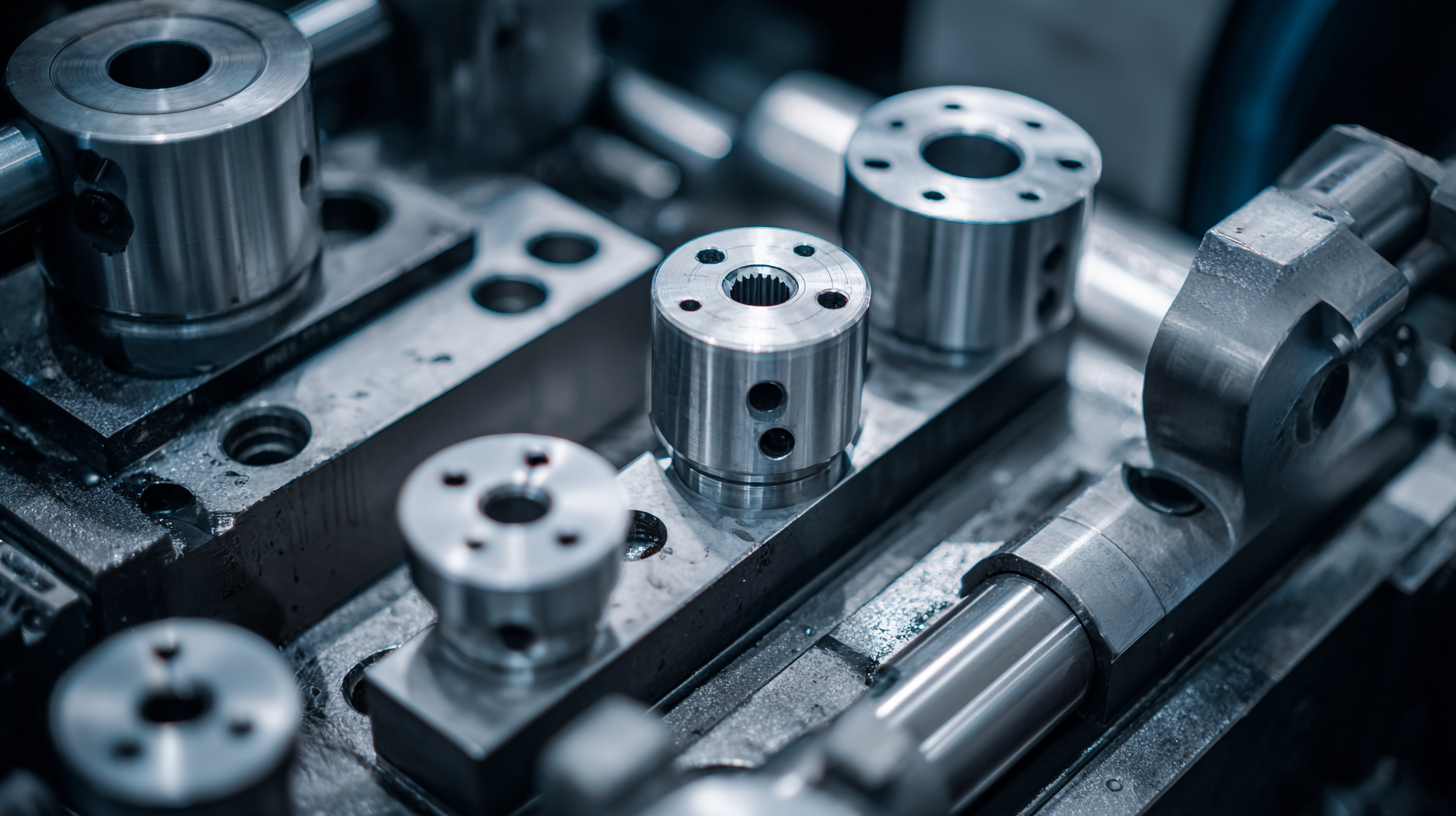

The advancements in technology, such as automation and additive manufacturing, are paving the way for innovative approaches to machining steel components. These trends not only enhance precision and decrease waste but also open the door to new possibilities in product design and functionality. Observing these changes allows manufacturers to stay ahead of the curve and adapt to the growing demands of their markets.

The advancements in technology, such as automation and additive manufacturing, are paving the way for innovative approaches to machining steel components. These trends not only enhance precision and decrease waste but also open the door to new possibilities in product design and functionality. Observing these changes allows manufacturers to stay ahead of the curve and adapt to the growing demands of their markets.

As we delve deeper into the top five trends shaping the future of machined steel parts, it is essential to recognize how they will not only influence existing manufacturing practices but also foster a more sustainable and efficient industry. The insights ahead will provide a comprehensive overview of how these trends are set to revolutionize our understanding of machined steel parts in the coming years.

As we look ahead to 2025, the manufacturing landscape is on the verge of a significant transformation driven by innovative materials that are revolutionizing machined steel parts. According to a recent report from Research and Markets, the global steel manufacturing market is projected to grow at a CAGR of 3.6% from 2021 to 2026, signaling a robust demand for advanced materials that enhance performance and durability. This increasing demand is pushing manufacturers to explore alternatives such as high-strength alloys and composites, which not only reduce weight but also improve corrosion resistance, thereby extending the lifespan of machined parts.

Furthermore, 3D printing technology is emerging as a game-changer in the production of machined steel components. A study by Wohlers Associates highlights that the metal 3D printing market is expected to reach $1.45 billion by 2026, with an annual growth rate of over 20%. This trend allows for more complex geometries and customizations that traditional manufacturing processes cannot achieve, leading to a more efficient production line and reducing material wastage. As businesses embrace these innovative materials and technologies, we can expect a marked shift in manufacturing practices and an enhancement in the overall quality of machined steel parts.

| Trend | Description | Expected Impact | Innovative Material Example | Sustainability Rating |

|---|---|---|---|---|

| Advanced Alloys | Utilizing custom alloy compositions for enhanced performance. | Improved durability and strength in machined steel parts. | Titanium Steel Alloys | High |

| Additive Manufacturing | 3D printing technologies to produce complex shapes and designs. | Reduction in waste and lead times. | Steel-Polymer Composites | Medium |

| Smart Manufacturing | Integration of IoT and AI to optimize machining processes. | Enhanced efficiency and real-time monitoring. | Data-Driven Steel Alloys | High |

| Recycling and Reuse | Focus on circular economy practices in material sourcing. | Reduced environmental footprint and resource conservation. | Recycled Steel Alloys | Very High |

| Surface Treatments | Innovative coatings for enhanced wear and corrosion resistance. | Longer lifespan of machined components. | Ceramic-Coated Steel | Medium |

As the manufacturing industry heads towards 2025, the integration of automation in the production of machined steel parts is set to redefine operational efficiency. Smart manufacturing leverages advanced technologies to create a cohesive environment where machines, systems, and human operators collaborate effectively. This paradigm shift is driven by cognitive automation, which utilizes real-time data to enhance decision-making processes and ensure high-quality outputs. By integrating AI and machine learning, manufacturers can significantly improve production reliability and reduce downtime, addressing the growing demand for precision and efficiency in steel part fabrication.

Recent partnerships among technology leaders exemplify the momentum of automation in enhancing manufacturing practices. Innovations in CNC machining and metal fabrication equipment have become crucial, as companies seek scalable solutions that adapt to rapidly changing market demands. The upcoming ET Smart Factory Summit 2025 aims to bring together industry experts to discuss these transformative trends, focusing on the challenges and opportunities that lie ahead for the Indian manufacturing landscape. As we move forward, embracing automation and AI-driven strategies will be essential for maintaining a competitive edge in the evolving market.

The manufacturing industry is undergoing significant transformation driven by sustainability trends, particularly in steel machining. As global awareness of environmental issues grows, manufacturers are increasingly adopting eco-friendly practices to reduce their carbon footprint and enhance energy efficiency. The shift towards green steel production is particularly noteworthy, with projections indicating a rapid growth in this sector, anticipated to reach USD 19.4 billion by 2029. This surge reflects a broader commitment within the industry to integrate sustainable materials and processes, showcasing a collective effort to meet both regulatory demands and consumer preferences for environmentally responsible products.

Moreover, the implementation of adaptive reuse strategies is becoming prevalent among manufacturers looking to minimize waste and maximize resource efficiency. By repurposing existing structures and materials, companies can effectively cut down on emissions and create new operational efficiencies. This approach not only contributes to sustainability but also aligns with corporate social responsibility objectives that prioritize environmental stewardship. As these trends evolve, the manufacturing landscape is poised to embrace innovative solutions that balance profitability with ecological impact, ensuring that the industry remains resilient in an ever-changing global market.

The manufacturing industry is undergoing a significant transformation fueled by advanced technologies that are reshaping the production of machined steel parts. Automation and robotics play a crucial role in boosting efficiency and precision, reducing human error and labor costs. Additionally, the implementation of IoT (Internet of Things) technologies allows for real-time monitoring, enabling manufacturers to optimize processes and predict maintenance needs, thus minimizing downtime.

Tips: When integrating new technologies into your manufacturing processes, start with a comprehensive evaluation of your existing systems. Identify pain points and areas where technology can provide the most value. Training your workforce to adapt to these new technologies is equally essential as it ensures a smooth transition and maximizes the benefits of these innovations.

Another trend impacting machined steel parts is the rise of additive manufacturing, or 3D printing. This technology allows for complex geometries that traditional methods cannot achieve, resulting in lighter and more efficient designs. Alongside this, advanced materials and alloys are being developed, offering enhanced durability and performance under extreme conditions.

Tips: Always stay informed about the latest materials and technologies in the field. Engaging with suppliers and industry experts can open avenues for innovation and keep your business at the forefront of manufacturing advancements.

In 2025, the manufacturing industry is increasingly prioritizing customization and flexibility to meet diverse industry needs. This shift is driven by the growing demand for tailored solutions that address specific challenges across various sectors. The trend toward flexibility is not only shaping product designs but also influencing manufacturing processes. By embracing adaptability, companies can significantly enhance efficiency and optimize their operations, allowing them to respond swiftly to market changes and customer preferences.

Moreover, the impact of advanced technologies such as automation and flexible packaging is notable. Automation tools are streamlining workflows, enabling manufacturers to eliminate inefficiencies without needing extensive coding expertise. Additionally, the flexible packaging market is evolving, with a focus on sustainable and lightweight solutions that cater to the dynamic needs of consumers and businesses. As industries strive for a zero-loss approach, the integration of customization and flexibility in manufacturing processes becomes essential for maintaining competitiveness and ensuring customer satisfaction.