Aluminum parts manufacturing plays a crucial role in various industries, ranging from automotive to aerospace, and is increasingly becoming a significant contributor to the global economy. According to a report by Research and Markets, the global aluminum die casting market is anticipated to grow at a CAGR of approximately 7% between 2023 and 2028, highlighting the rising demand for aluminum components in manufacturing processes. This surge underscores the material's lightweight, strength, and corrosion resistance, making it a preferred choice for manufacturers aiming to enhance efficiency and reduce environmental impact.

Industry experts emphasize the importance of aluminum parts manufacturing in streamlining production and meeting contemporary design requirements. John Smith, a leading expert in manufacturing technologies, states, "The evolution of aluminum parts manufacturing is essential for innovation in modern engineering, as it allows for complex designs that are both durable and lightweight." This sentiment resonates through the industry as companies increasingly leverage advanced manufacturing techniques, including additive manufacturing and precision machining, to optimize their operations and adapt to market demands. The ongoing advancements in aluminum parts manufacturing not only pave the way for enhanced product performance but also contribute to sustainability efforts by reducing material waste and energy consumption.

Aluminum parts manufacturing refers to the process of producing components made from aluminum through various methods such as machining, casting, and extrusion. This manufacturing sector is significant due to aluminum's unique properties, including its lightweight nature, resistance to corrosion, and excellent conductivity. According to the Aluminum Association, the global aluminum market is projected to reach approximately 181 million metric tons by 2025, highlighting the material's growing demand across various industries, including aerospace, automotive, and construction.

The importance of aluminum parts manufacturing stems from its application in creating components that enhance the efficiency and performance of end products. For instance, in the automotive industry, the use of aluminum parts can lead to weight reductions of up to 30%, which directly improves fuel efficiency and reduces emissions. In aerospace, lighter aluminum components contribute to decreased fuel costs and extended range capabilities for aircraft. Thus, aluminum parts manufacturing is a pivotal aspect of modern industry, significantly influencing sustainability and innovation.

Tips: When considering aluminum for manufacturing projects, always assess the specific alloy's properties to ensure it meets your application requirements. Regularly monitor advancements in aluminum production technologies, as new techniques can significantly impact cost and efficiency. Additionally, ensure compliance with industry standards for quality and safety to maintain the integrity of your manufactured products.

| Dimension | Description | Example Applications | Benefits |

|---|---|---|---|

| Material Properties | Lightweight, resistance to corrosion, good thermal conductivity. | Aerospace components, automotive parts, consumer electronics. | Reduces weight, improves fuel efficiency, enhances durability. |

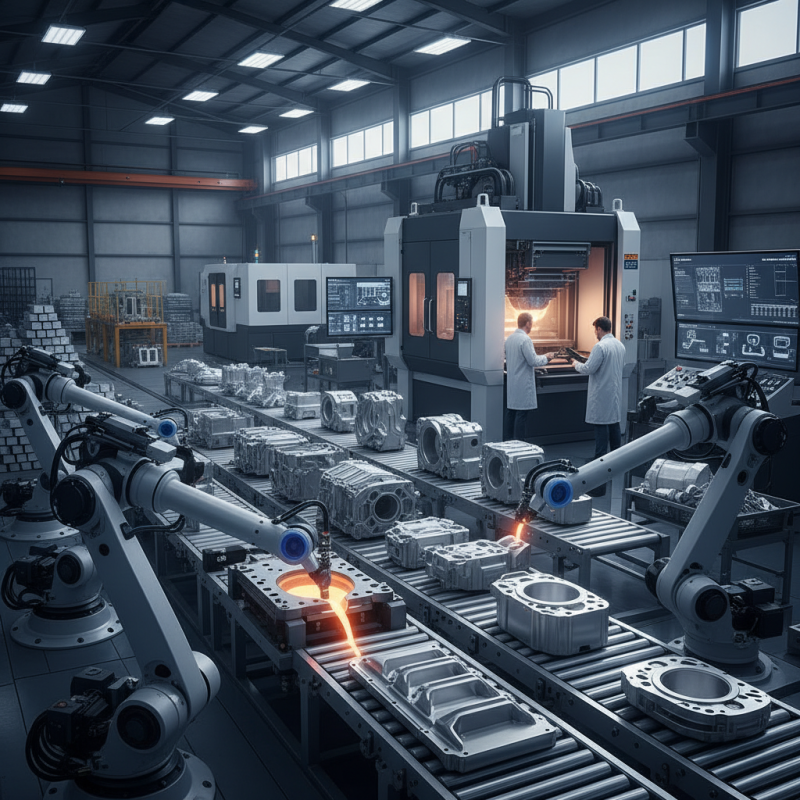

| Manufacturing Processes | Includes extrusion, casting, machining, and welding. | Structural frames, engine blocks, electrical housings. | Versatile production, tailored designs, reduced waste. |

| Market Demand | Increasing demand for lightweight materials in various industries. | Transportation, construction, food and beverage packaging. | Cost-effective solutions, sustainability, and energy efficiency. |

| Environmental Impact | Recyclable material with lower carbon footprint compared to steel. | Green building components, renewable energy systems. | Promotes recycling, lowers environmental impact. |

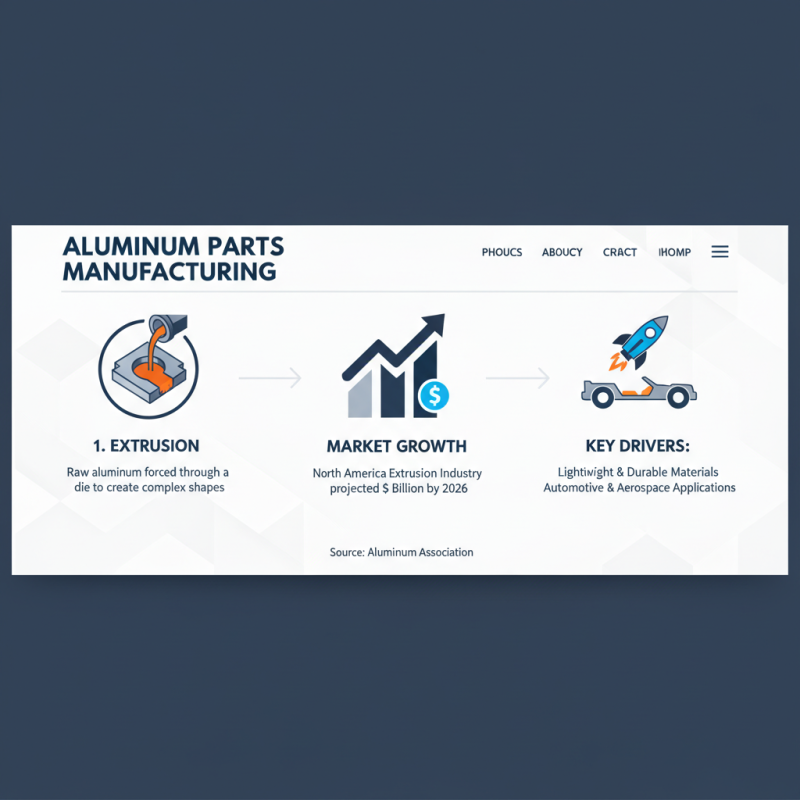

Aluminum parts manufacturing is a critical sector within the broader manufacturing industry, characterized by a variety of key processes that ensure precision and efficiency. One of the primary methods used is extrusion, where raw aluminum is forced through a die to create complex shapes. According to a report from the Aluminum Association, the extrusion industry in North America alone is projected to reach a market size of over $3 billion by 2026, driven by the growing demand for lightweight and durable materials in automotive and aerospace applications.

Another significant process is machining, which involves subtracting material from a solid piece of aluminum to achieve the desired dimensions and surface finish. This process is vital for creating intricate components that meet strict tolerances. According to a study by MarketsandMarkets, the global CNC machine market, which heavily utilizes aluminum, is expected to grow from $63.4 billion in 2020 to $106.9 billion by 2026, indicating a strong trend towards automation and precision manufacturing in the aluminum parts sector.

Finally, casting is also a prevalent method employed in aluminum parts manufacturing. This technique involves pouring molten aluminum into a mold to create complex shapes that would be difficult to achieve through other methods. The global aluminum casting market is estimated to reach $100 billion by 2024, emphasizing the importance of this process in producing components for a diverse range of industries, including construction, electronics, and transportation. The versatility and efficiency of these processes are what make aluminum an essential material across various industries.

Aluminum parts play a crucial role in various industries due to their lightweight, high strength, and corrosion resistance. In the automotive industry, aluminum components are extensively used to enhance fuel efficiency and performance. By replacing heavier materials with aluminum, manufacturers can reduce the overall weight of vehicles, leading to lower fuel consumption and improved handling. Additionally, aluminum is favored in the aerospace sector for its exceptional strength-to-weight ratio, enabling the production of high-performance aircraft with increased payload capacities.

In the construction field, aluminum parts contribute to energy efficiency and durability. Aluminum windows and doors are not only aesthetically pleasing but also provide excellent thermal insulation, reducing energy costs for consumers. The architectural industry has embraced aluminum for structural applications, using it in facades and roofing systems to combine functionality with modern design aesthetics.

Tips: When considering aluminum parts for your project, ensure that you choose the right alloy for specific applications. Different aluminum alloys offer distinct properties, such as higher strength or improved corrosion resistance, depending on the intended use. Furthermore, partnering with reliable manufacturers can guarantee quality and precision in the production of aluminum components, resulting in enhanced performance and longevity. Ensuring proper finishing and treatment of aluminum parts can also significantly increase their durability and aesthetic appeal.

Aluminum has become a cornerstone material in manufacturing due to its unique combination of properties that cater to diverse industrial needs. One of the main advantages of using aluminum is its lightweight nature, which allows for easier handling and transport compared to heavier metals. This quality significantly reduces energy costs in applications such as aerospace and automotive, where weight savings translate directly to improved fuel efficiency. Additionally, aluminum's excellent strength-to-weight ratio ensures that products can maintain structural integrity while remaining lightweight.

Another notable advantage of aluminum is its resistance to corrosion. Unlike many metals that can rust and deteriorate over time, aluminum forms a protective oxide layer that enhances its durability in various environments. This characteristic makes aluminum especially valuable in manufacturing components for outdoor applications, marine environments, and even in construction. Furthermore, aluminum is highly malleable and can be easily extruded or molded, allowing manufacturers to create complex shapes and designs with precision. These attributes together make aluminum an ideal choice for a wide range of industries, promoting innovation and efficiency in product development.

This chart illustrates the significant advantages of aluminum in manufacturing processes. The characteristics such as lightweight, corrosion resistance, machinability, electrical conductivity, and recyclability are crucial for various industrial applications.

The production of aluminum parts faces several challenges that industry stakeholders must navigate to maintain efficiency and competitiveness. One major challenge is the variability in the quality of raw aluminum materials, which can lead to inconsistencies in the manufacturing process. Variations in alloy composition can affect the mechanical properties of the final products, making it crucial for manufacturers to implement rigorous quality control measures. Additionally, the recycling of aluminum poses logistical challenges, as the collection, sorting, and processing of recycled materials require advanced technologies and can be resource-intensive.

Looking toward the future, trends in aluminum parts production indicate a shift towards more sustainable practices and technological advancements. Manufacturers are increasingly adopting additive manufacturing techniques, which allow for the creation of complex geometries that traditional methods cannot achieve. This not only enhances design possibilities but also reduces material waste.

Furthermore, the integration of Industry 4.0 technologies, such as automation and the Internet of Things (IoT), is expected to streamline operations, improve production efficiency, and enable real-time monitoring of the manufacturing process. As these trends continue to evolve, the industry will likely see enhanced capabilities in aluminum parts production, contributing to its growth and adoption in various sectors.