As businesses strive for growth in an increasingly competitive market,

understanding the benefits of contract manufacturing

has become essential. A recent report by IBISWorld indicates that the

contract manufacturing industry is expected to reach a value of

$188 billion by 2024, highlighting its significance in modern business operations.

This model allows companies to leverage specialized expertise, reduce overhead costs, and enhance scalability, enabling them

to focus on core competencies while expanding their product offerings. Moreover,

a study by Deloitte revealed that 79% of manufacturers believe that outsourcing

production through contract manufacturing can lead to faster time-to-market

for new products. By integrating contract manufacturing into their strategies, growing businesses can access advanced technologies

and streamlined processes, positioning themselves for success in a dynamic economic landscape.

As businesses strive for growth in an increasingly competitive market,

understanding the benefits of contract manufacturing

has become essential. A recent report by IBISWorld indicates that the

contract manufacturing industry is expected to reach a value of

$188 billion by 2024, highlighting its significance in modern business operations.

This model allows companies to leverage specialized expertise, reduce overhead costs, and enhance scalability, enabling them

to focus on core competencies while expanding their product offerings. Moreover,

a study by Deloitte revealed that 79% of manufacturers believe that outsourcing

production through contract manufacturing can lead to faster time-to-market

for new products. By integrating contract manufacturing into their strategies, growing businesses can access advanced technologies

and streamlined processes, positioning themselves for success in a dynamic economic landscape.

Contract manufacturing has become an essential strategy for expanding enterprises, offering a myriad of benefits that can propel a business to new heights. According to a report from the National Council of Textile Organizations (NCTO), companies that leverage contract manufacturing can reduce their production costs by up to 30%. This significant cost savings is crucial for growing businesses, which often operate with limited resources. By outsourcing production, these companies can focus on core competencies such as research and development, marketing, and customer service, ultimately driving innovation and enhancing product quality.

Contract manufacturing has become an essential strategy for expanding enterprises, offering a myriad of benefits that can propel a business to new heights. According to a report from the National Council of Textile Organizations (NCTO), companies that leverage contract manufacturing can reduce their production costs by up to 30%. This significant cost savings is crucial for growing businesses, which often operate with limited resources. By outsourcing production, these companies can focus on core competencies such as research and development, marketing, and customer service, ultimately driving innovation and enhancing product quality.

Furthermore, contract manufacturing provides access to advanced technologies and expertise that may not be available in-house. A study by Deloitte indicates that 79% of manufacturers cite improved quality as a key benefit of outsourcing production. This access enables growing businesses to scale operations quickly, respond to market demands, and maintain competitive advantage without the hefty capital investment typically required for new facilities or equipment. As such, contract manufacturing not only helps in managing costs but also enhances efficiency, allowing enterprises to adapt to changing market trends with agility.

When choosing a contract manufacturer, businesses should consider several key factors to maximize the benefits of this collaboration. First and foremost, assessing the manufacturer's capabilities and expertise aligned with the business's industry is crucial. This includes understanding the production processes, technology employed, and quality control measures in place. A manufacturer with a proven track record in a similar field can significantly enhance product quality and reliability.

Additionally, communication and cultural fit between the business and the manufacturer can greatly influence the success of the partnership. Clear communication ensures that project specifications are understood, timelines are met, and any potential issues are addressed promptly. Furthermore, considering the geographic location of the contract manufacturer can impact logistical efficiency and costs. By selecting a manufacturer who is strategically located, businesses can benefit from reduced shipping times and costs, enhancing their overall supply chain efficiency.

Contract manufacturing is becoming an essential strategy for businesses aiming for flexibility and scalability, particularly in the bio/pharmaceutical sector. Recent deals, such as the one involving a U.S. affiliate of a Korean biotech company, underscore the trend towards strategic partnerships that enhance production capabilities. As reported, the U.S. healthcare contract development and manufacturing organization market is projected to reach a substantial USD 65.3 billion by 2024, reflecting robust growth in response to increasing demand for flexible manufacturing solutions.

The advantages of adopting contract manufacturing extend beyond cost savings; they significantly contribute to a company’s ability to scale operations quickly. For instance, companies like Stevanato Group are expanding their drug delivery system manufacturing capacity as part of an optimization plan, ensuring they can meet diverse customer needs without the overhead of maintaining large in-house operations. This trend highlights how contract manufacturing can allow firms to focus on core competencies while rapidly adapting to market changes.

**Tips for Businesses:**

1. Evaluate potential contract manufacturers based on their ability to adapt to fluctuating demands in your specific industry.

2. Consider the geographical location of your contract manufacturing partner to optimize logistics and reduce lead times, enhancing overall operational efficiency.

Contract manufacturing has emerged as a vital strategy for growing businesses, primarily due to its cost-effectiveness. According to a report by the National Association of Manufacturers, nearly 60% of companies that utilize contract manufacturing save between 10% to 30% on production costs compared to maintaining in-house capabilities. This reduction is largely attributed to lower labor costs, streamlined operations, and the ability to leverage the expertise of specialized manufacturers without significant capital investment.

Moreover, the flexibility offered by contract manufacturing allows businesses to scale production up or down quickly in response to market demands, significantly reducing overhead costs. A study by Deloitte suggests that companies leveraging contract manufacturing can achieve a return on investment (ROI) of over 20% within the first year, largely due to decreased expenditure on facilities and equipment. As markets continue to evolve, utilizing contract manufacturing not only enhances operational efficiency but also allows growing businesses to focus their resources on innovation and customer engagement, driving long-term success.

The following chart illustrates the cost-effectiveness of contract manufacturing over in-house production for growing businesses across various dimensions. The data considers factors such as labor costs, material costs, and overhead expenses.

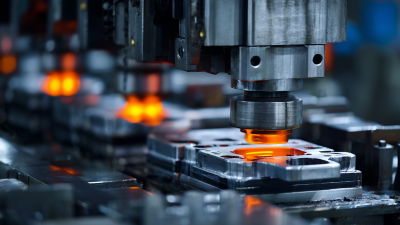

Contract manufacturing plays a critical role in enhancing quality and innovation for growing businesses, especially within the plastic manufacturing sector. By outsourcing plastic production to specialized service providers, companies can leverage advanced techniques such as injection molding, extrusion, blow molding, and thermoforming. This not only enables businesses to focus on their core competencies, but also ensures that they access high-quality materials and state-of-the-art manufacturing processes. For instance, the increasing use of plastics in household appliances highlights how outsourcing to experts can drive improvements in product quality and performance.

Furthermore, contract manufacturing fosters an environment of innovation. As businesses collaborate with experienced manufacturers, they are exposed to new ideas and cutting-edge technologies that can transform their product offerings. In regions like Hubei, where technological contract values surged significantly, it is evident that partnerships with contract manufacturers can lead to notable advancements in production capabilities. The integration of new techniques and materials contributes not only to quality enhancements but also to the overall competitiveness of businesses in an increasingly challenging market.