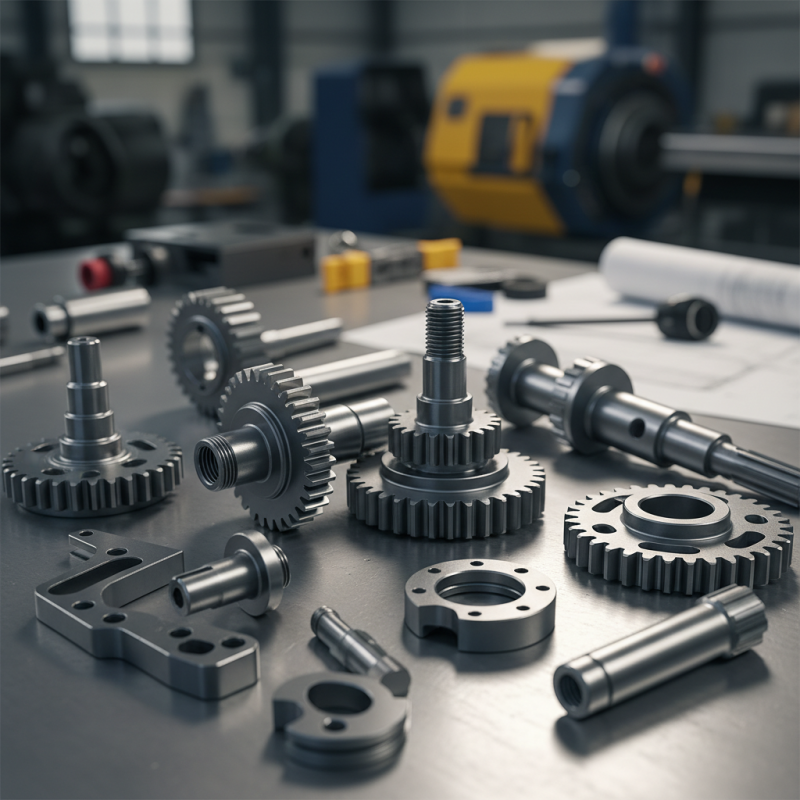

In modern manufacturing, the choice of materials can significantly impact efficiency and quality. Machined steel parts are increasingly favored for their durability and precision. According to John Smith, a leading expert in the machined parts industry, “Machined steel parts offer unparalleled strength and reliability.” This credibility has made them essential in various sectors, including aerospace and automotive.

Choosing the right materials can be daunting. Machined steel parts stand out due to their ability to withstand harsh conditions. They can be tailored to meet specific requirements, which enhances performance. However, manufacturers must consider cost-effectiveness and production time. The balance between quality and expense is crucial.

The integration of machined steel parts is not without challenges. Technical issues may arise during production. Moreover, sourcing high-quality steel is vital but often complicated. Companies must reflect on their processing methods and supply chain strategies. These reflections can lead to better decision-making. Understanding the risks involved is key to leveraging the benefits of machined steel parts effectively.

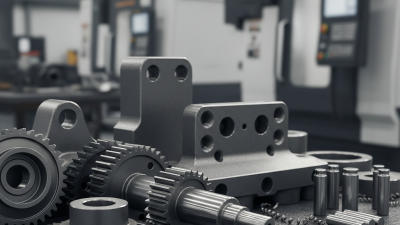

In precision engineering, machined steel parts offer significant advantages. Their consistency and durability are unmatched. The precision in machining allows for tight tolerances. These components can endure extreme conditions. This reliability is crucial for various applications. Manufacturers often rely on the exact specifications that machined steel provides.

Not all machined steel components are perfect. Some may have minor surface imperfections. These can occur during the manufacturing process. However, engineers often find ways to mitigate such issues. These small flaws usually do not compromise functionality. This attention to detail can enhance overall performance.

Another consideration is the cost. High-quality machined parts can be more expensive. Yet, their longevity and resilience often justify the price. Investing in precision machined steel can lead to lower long-term costs. It’s essential to evaluate the benefits against the investment.

| Benefit | Description | Applications |

|---|---|---|

| Durability | Machined steel parts are known for their strength and long-lasting durability. | Automotive, Aerospace, Heavy Machinery |

| Precision Manufacturing | Allows for tight tolerances and highly accurate dimensions in production. | Robot Parts, Medical Devices, Aerospace Components |

| Cost-Effective | While initial costs may be high, the longevity and durability reduce overall lifecycle costs. | Industrial Equipment, Construction Tools |

| Versatility | Machined steel can be used across various industries and applications. | Consumer Goods, Electronics, Transportation |

| Corrosion Resistance | With proper treatment, machined steel can resist rust and corrosion. | Marine, Oil and Gas, Chemical Processing |

Machined steel components offer enhanced durability and strength, which are crucial in modern manufacturing. Their resilience allows them to withstand extreme conditions. Whether in automotive parts or industrial machines, these components provide reliable performance over time. The strength of machined steel significantly reduces the risk of failures. This is vital for maintaining productivity in manufacturing processes.

Having high durability means parts last longer. However, this can create a mindset where maintenance is overlooked. Regular checks are still essential. Small flaws can evolve into big problems. It’s important not to become complacent with steel's sturdiness.

Tip: Always inspect machined components regularly, even if they look fine. A good practice is to create a maintenance schedule. Keeping records of inspections can help spot patterns in wear and tear. This proactive approach can save costly downtimes and extend the lifespan of your equipment. Remember, while strength is a key advantage, consistent oversight is crucial for optimal performance.

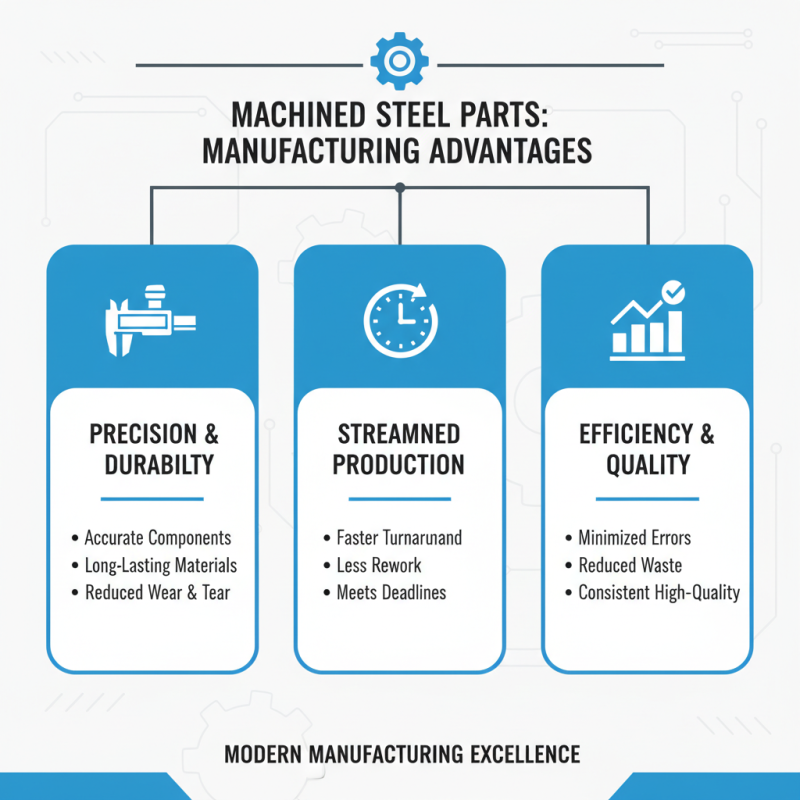

Machined steel parts are crucial in modern manufacturing. The cost-effectiveness of using these materials stands out. Machining steel offers precision, reducing waste during production. This precision directly impacts costs. Fewer errors mean lower rework expenditures. Over time, this efficiency leads to significant savings.

However, the process isn't without challenges. Initial setup costs for machining can be high. Quality control is essential to avoid costly mistakes. Sometimes, fluctuations in steel prices can affect overall expenses. The need for skilled labor adds another layer of costs. Efficient training programs can help mitigate this issue. Finding the balance between cost and quality remains an ongoing challenge.

Despite these hurdles, the long-term benefits are clear. Machined steel exhibits durability and strength. Products made from these parts often last longer, reducing replacement costs. Additionally, their versatility allows for use in various applications. Manufacturers must continuously evaluate processes. This reflection helps to maximize the potential of machined steel in their operations.

Machined steel parts play a critical role in modern manufacturing. These components are precise and durable, often leading to significant reductions in production time. The streamlined process of machining allows for quicker turnaround. High precision means fewer errors and less waste. This efficiency helps businesses meet tight deadlines while maintaining high-quality standards.

However, there are challenges to consider. Not all designs translate well to machined steel. Some parts may require complex setups or tooling adjustments. Such complexities can lead to unforeseen delays. Manufacturers must remain aware of these pitfalls. Proper planning and design iteration can minimize these issues.

Moreover, while machining can reduce production complexity, it's not a one-size-fits-all solution. The reliance on automated systems may risk overlooking traditional craftsmanship. Balancing technology and human skill is essential for optimal results. Embracing these insights can elevate production processes to new heights.

Machined steel parts are highly versatile and play a crucial role in various industries. In aerospace, for example, precision-engineered steel components are vital for ensuring safety and reliability. The Aerospace Industries Association reports that nearly 79% of aerospace manufacturers rely on machined parts to meet stringent safety standards. These parts withstand extreme conditions, from high temperatures to significant pressure changes.

In the automotive sector, the versatility of machined steel components is evident. The industry uses them for engine blocks, transmission housings, and more. According to the American Iron and Steel Institute, 40% of the weight of a vehicle comes from steel parts. However, integrating these parts is not without challenges. Manufacturers occasionally face difficulties in maintaining tolerances, which can lead to costly reworks.

Machined steel also finds applications in robotics and automation. Industries are increasingly adopting automation, driving a demand for durable steel parts. Statistics show that the global robotics market is expected to grow significantly by 2025. This trend highlights the increasing reliance on machined parts to build sophisticated robotic systems. Yet, one must consider supply chain constraints that could disrupt the availability of raw materials.