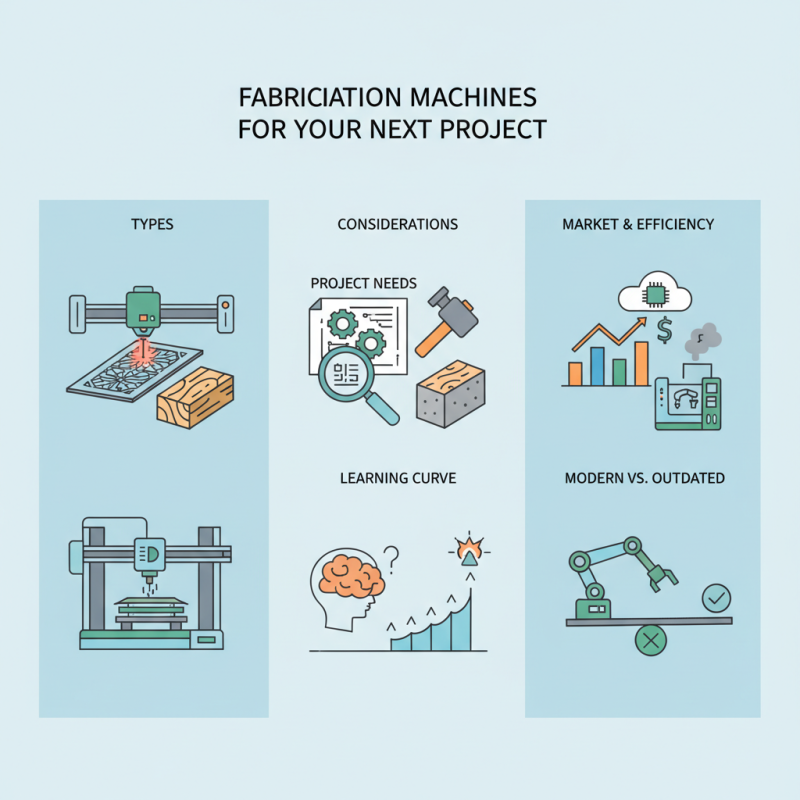

In today's manufacturing landscape, choosing the right fabrication machine is crucial. According to a recent report by Market Research Future, the global fabrication machinery market is projected to reach $54 billion by 2025. This rapid growth highlights the significance of advanced technology in optimizing production processes. As industry expert Dr. Emily Jacobs stated, "The right fabrication machine can transform the efficiency and quality of any project."

Fabrication machines come in various forms, including laser cutters, CNC routers, and 3D printers. Selecting the best option for your project requires understanding your specific needs. For instance, a high-precision laser cutter might be ideal for intricate designs, while a robust CNC router may suit heavy materials. However, many users often underestimate the learning curve associated with these machines. Mistakes in setup or operation can lead to costly delays and waste.

Considering the rapid evolution of fabrication technology, keeping up with market trends is essential. Many companies still rely on outdated machines, leading to inefficiencies. The challenge lies in balancing modern capabilities with practical investment decisions. Thus, finding the right fabrication machine is not just about specifications; it involves careful evaluation of your operational goals.

When selecting fabrication machines, understanding key criteria is essential. The right machine can significantly impact project success. Consider precision and versatility as top factors. A recent report states that precision in fabrication can reduce material wastage by 30%. High precision ensures every cut and joint fits perfectly, minimizing rework and saving time.

Evaluate the machine's capacity. Heavy-duty machines can handle larger projects and materials. Data suggests that businesses with versatile machines experience a 25% increase in productivity. This adaptability can make it easier to switch between different types of projects without significant downtime.

Cost effectiveness also plays a critical role in decision-making. While initial prices can be high, long-term savings matter. Equipment that offers durability often results in lower maintenance costs and fewer replacements. A study highlighted that companies investing wisely in fabrication tools can see returns on investment within two to three years. Finding the balance between cost and functionality is crucial, as is reflecting on your current workflow needs.

This chart represents the efficiency ratings of various fabrication machines based on key performance criteria such as speed, accuracy, versatility, and ease of use. Higher ratings indicate better performance across these dimensions.

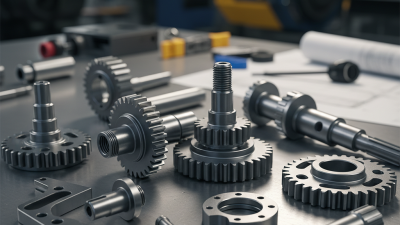

Fabrication machines come in various types, each designed for specific tasks.

Laser cutters are popular for their precision. They use intense light to cut materials like metal and acrylic with great accuracy.

Plasma cutters, on the other hand, can slice through thicker metals quickly. They are less precise than laser cutters but very effective for rough cuts.

CNC machines are another type worth mentioning. They are computer-controlled and can create intricate designs from a range of materials.

Setting them up can be time-consuming, and they often require detailed programming knowledge. In contrast,

3D printers are revolutionizing fabrication. They build objects layer by layer, opening new possibilities for creativity.

However, they often have limitations in material strength.

Each type of machine has its pros and cons. Blending multiple machines can enhance project outcomes. While fabrication machines are powerful tools, they can also be challenging to master.

Learning from mistakes along the way is essential. Adapting techniques and experimenting with machines you are less familiar with can lead to unexpected results.

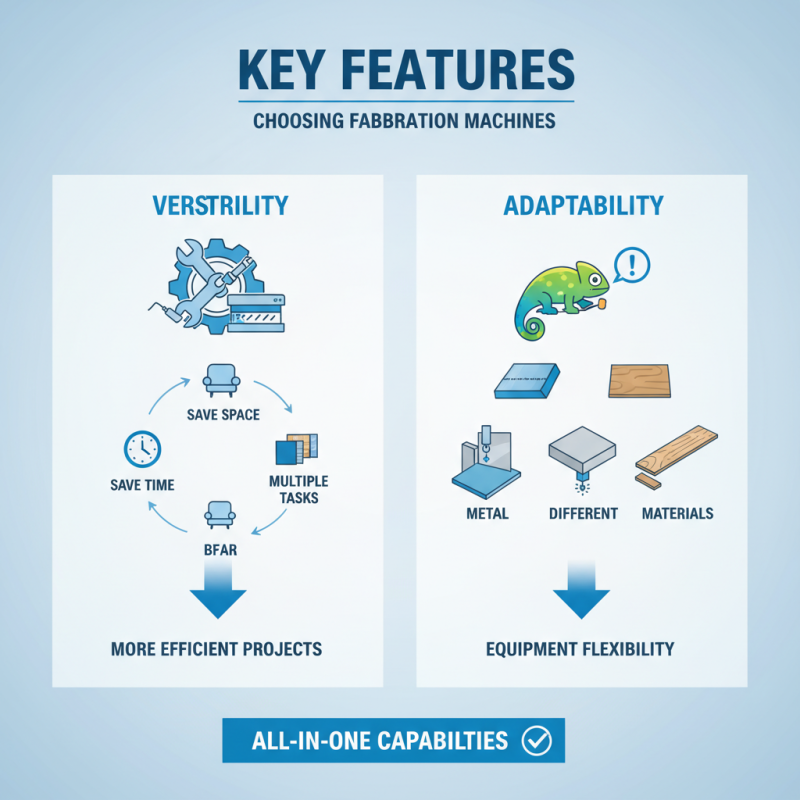

When choosing fabrication machines, several key features are essential. First, look for versatility. A machine that can handle multiple tasks will save time and space. It's crucial to have equipment that adapts to different materials. This versatility can make a project more efficient.

Consider the accuracy of the machine. Precision is vital for high-quality results. Any small mistakes can ruin an entire project. It's worth investing in tools that calibrate easily and maintain consistent performance. A focus on precision often leads to better craftsmanship.

Lastly, support and maintenance options matter. Equipment can face issues over time. Having access to reliable support can minimize downtime. Even the best machines require occasional repairs. Make sure to choose machines that come with good guarantees. Balancing these features may take some time, but it’s necessary for success.

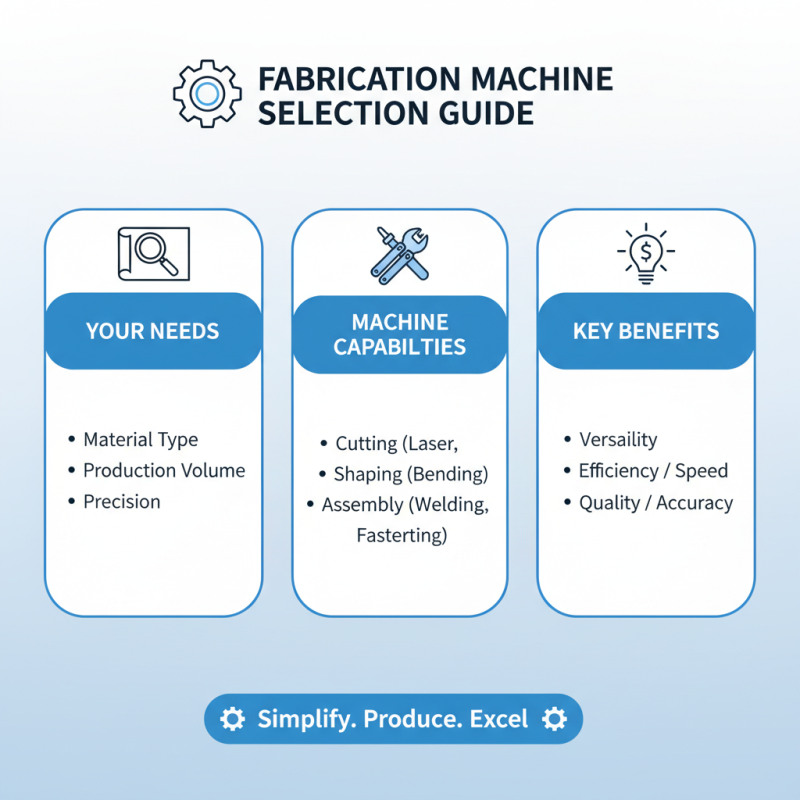

When selecting fabrication machines, it’s vital to consider your specific needs. Each machine offers unique features. The best options provide versatility and efficiency. Explore machines that can cut, shape, and assemble materials effectively. Focus on those that simplify tasks while maintaining quality.

Tips: Always analyze the space you have available. Some machines require more room than others. Assess your workflow too. A cluttered workspace can complicate operations. Think about how often you will use each machine. Over-purchasing leads to wasted resources.

Choosing the right machine can feel overwhelming. Research is essential. Not every machine is suitable for every project. Read reviews and user experiences. Reach out to industry peers for advice. Many machines look impressive but may not perform as expected. Prioritize reliability over flashy features. Make informed choices to ensure successful outcomes for your projects.

When considering fabrication machines, budget is critical. Industry reports indicate that a significant 70% of small businesses face financial constraints when investing in new machinery. A carefully planned budget can ensure you pick machines that meet your needs without jeopardizing your finances.

Evaluate the total cost of ownership, not just the initial price. This includes maintenance costs, energy consumption, and potential downtime losses. Reports suggest that high-quality machines can reduce operational costs by up to 30%. However, there's a risk in overspending on features you may never use. Focus on your core project needs and choose machines accordingly.

Look into financing options that align with your budget. Many fabrication machines can be costly, creating cash flow issues for new projects. Be cautious about entering into long-term loans, as they can strain your budget if unexpected costs arise. Reflecting on your financial situation is essential to avoid overextending yourself.