In the world of manufacturing, machine fabrication plays a crucial role in enhancing productivity. Different techniques exist, each with unique benefits and challenges. These methods can streamline processes but also require careful consideration.

Understanding these fabrication techniques is essential for optimizing production. Some methods may seem more efficient, yet they might not suit every project. For instance, advanced automation can save time but may require a significant initial investment.

Moreover, not every method guarantees quality. The effectiveness of machine fabrication hinges on choosing the right approach that aligns with specific production goals. Evaluating the pros and cons of each technique is vital. Each choice shapes the final output and impacts overall efficiency.

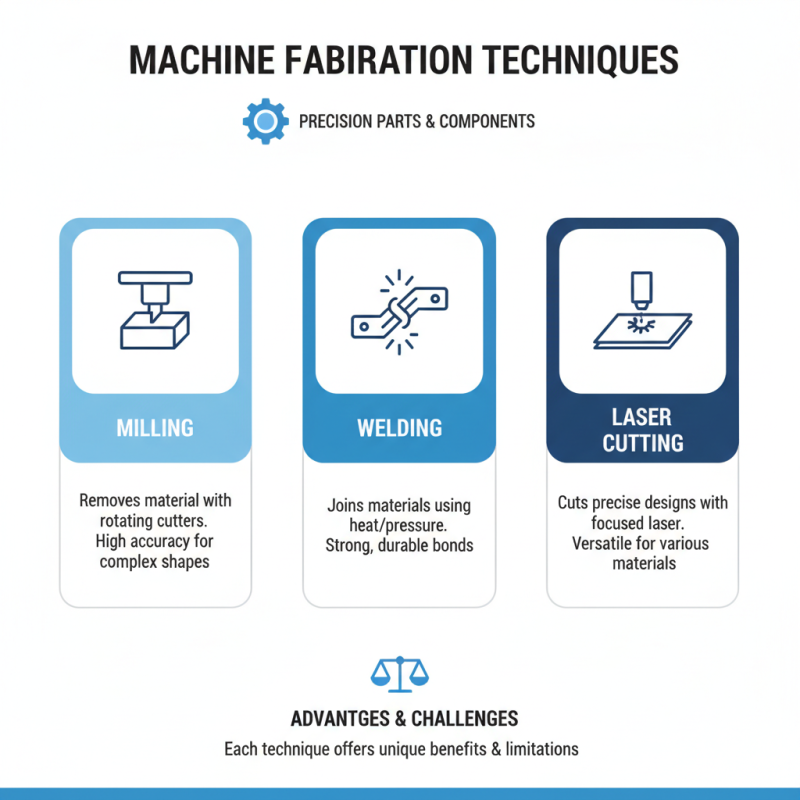

Machine fabrication techniques play a vital role in manufacturing and industry. These techniques help create precise parts and components. Common methods include milling, welding, and laser cutting. Each technique has its advantages and challenges.

Milling is effective for shaping materials. It involves removing material from a solid block. However, it can create waste. Sometimes, the final product lacks the desired surface finish. On the other hand, welding is essential for joining pieces together. It offers strong bonds, but poor technique can lead to weak joints. Laser cutting allows intricate designs but may require costly equipment.

Understanding these techniques is crucial. Fabricators need to recognize that each method has its flaws. Choosing the right technique depends on the project requirements. Balancing cost, time, and quality is necessary for effective production. Reflection on past projects can reveal outcomes that need improvement.

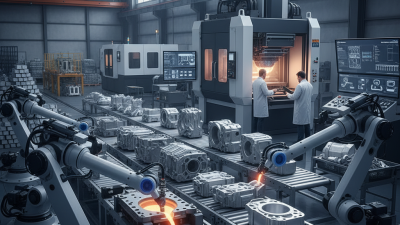

Traditional machining methods remain essential in the fabrication industry. These techniques, such as turning, milling, and drilling, have stood the test of time. They offer precision and reliability in producing intricate components. However, they also come with limitations. Traditional methods can be slow and costly, especially for large production runs.

One common issue is tool wear. As tools blunt, they require frequent replacement, leading to downtime. Moreover, these methods often generate waste. Material is removed to create the desired shape, which can be inefficient. Not all designs translate smoothly into machining processes. Some intricate designs can pose challenges, leading to unexpected errors.

In addition, skilled labor is crucial. Experienced machinists can adapt to variations, yet finding qualified personnel is increasingly difficult. This skill gap can affect production quality and timelines. While traditional machining holds value, it often necessitates a rethink. Investment in modern techniques may enhance efficiency and overcome some of these challenges. Adapting and evolving is key to remaining competitive in fabrication.

| Technique | Description | Advantages | Disadvantages | Best Use Case |

|---|---|---|---|---|

| Turning | Rotating a workpiece while cutting it to produce cylindrical parts. | High precision, good surface finish. | Limited to round shapes, slower for larger volumes. | Manufacturing shafts and cylindrical components. |

| Milling | Using rotating cutters to remove material from a stationary workpiece. | Highly versatile, can produce complex shapes. | Can be slower than turning, setup time can be long. | Creating flat surfaces, slots, and complex geometries. |

| Grinding | Using an abrasive wheel to finish workpieces to high precision. | Excellent for hard materials, achieves fine tolerances. | Not suitable for large quantities, slow process. | Finishing operations requiring tight tolerances. |

| Boring | Enlarging a hole or creating a precise internal surface. | High accuracy for hole dimensions. | Limited to circular holes, slower compared to drilling. | Machining existing holes in heavy parts. |

| Sawing | Using a saw blade to cut materials into desired shapes and sizes. | Cost-effective for large scale cutting. | Less precision than other methods, rough edges. | Cutting raw materials into manageable sizes. |

| Electrical Discharge Machining (EDM) | Using electrical discharges to machine conductive materials. | High precision, can machine complex features. | Limited to conductive materials, slower cycle times. | Creating intricate parts from hard materials. |

| Laser Cutting | Using laser beams to cut materials with precision. | Allows for intricate cuts, minimal material wastage. | Cost of equipment and maintenance can be high. | Thin materials and detailed designs. |

| Plasma Cutting | Using a plasma torch to cut through electrically conductive materials. | Fast and effective for thicker materials. | Less precise than laser cutting, can have rough edges. | Metal fabrication and general manufacturing. |

| 3D Printing | Additive manufacturing technique to create objects from digital files. | Flexibility in design, rapid prototyping. | Material limitations, slower for large quantities. | Prototyping and custom parts production. |

| Stamping | Using dies to shape and cut sheet metal. | High productivity for mass production. | Initial setup costs can be high, limited to sheet materials. | Automotive parts and metal components. |

Modern CNC machining has transformed the landscape of machine fabrication. This technology enables precise control over complex operations. As industries demand higher efficiency, CNC machines have become vital.

One key tip is to regularly calibrate your machines. Over time, even minor deviations can lead to significant inaccuracies. A daily check can save time and materials. Another useful idea is to invest in training. Proper training for operators enhances productivity. But always remember: more automation can lead to less hands-on experience. Balance is essential.

While CNC machining brings many advantages, challenges remain. Some machines can be costly to maintain. Downtime can hurt production schedules. It’s crucial to have backup plans in place. Additionally, consider the sustainability of your materials. Not all options are eco-friendly. Strive for solutions that minimize waste and enhance efficiency. Balancing functionality with environmental impact is challenging but necessary.

Additive manufacturing, often known as 3D printing, is reshaping how we approach production. This technique builds objects layer by layer, using materials like plastic, metal, and even bio-inks. Unlike traditional methods, additive manufacturing offers flexibility in design and rapid prototyping. It allows for complexity in shapes without excessive costs.

However, this revolutionary technology is not without challenges. The speed of production can be an issue when large volumes are needed. Additionally, quality control is crucial; not every printed item meets the required standards. Material limitations can hinder certain applications, and the choice of materials may affect durability. Companies find themselves needing to balance innovation with reliability.

Despite these imperfections, the potential of additive manufacturing is immense. Its ability to reduce waste and allow for customization makes it attractive for various industries. As this technology continues to evolve, ongoing research is essential to overcome its limitations. The future of production lies in finding the right balance between scalability and maintaining quality.

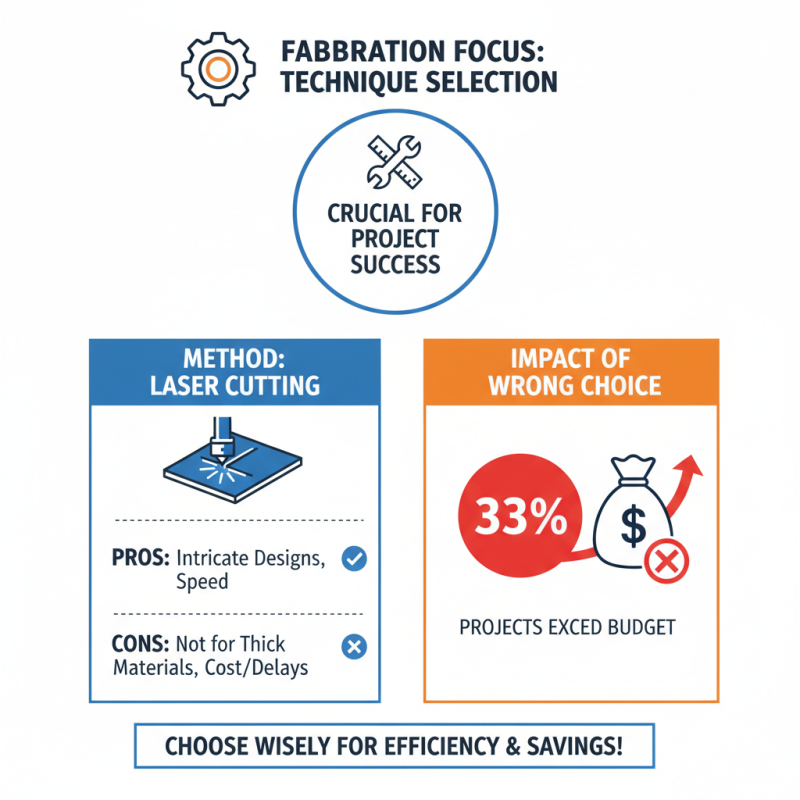

Selecting the right fabrication technique is critical for project success. Each method offers unique advantages and challenges. For instance, laser cutting can produce intricate designs quickly. However, it might not be the best choice for thick materials, which could lead to increased costs or delays. Reports indicate that 33% of projects exceed their budgets due to improper selection of techniques.

In contrast, welding remains a versatile option. It can join various metals effectively. Yet, it requires skilled labor, and quality can vary. Data suggests that companies often underestimate training needs, resulting in rework and wasted materials. Moreover, techniques like 3D printing offer speed but may not deliver the strength needed for all applications. Balancing speed and durability can be tricky.

Understanding production volume and material type is essential. A technique suitable for low-volume runs may not be ideal for mass production. An average of 25% of businesses faced issues when scaling up due to inappropriate fabrication choices. Each project's unique requirements must guide technique selection to avoid costly mistakes.