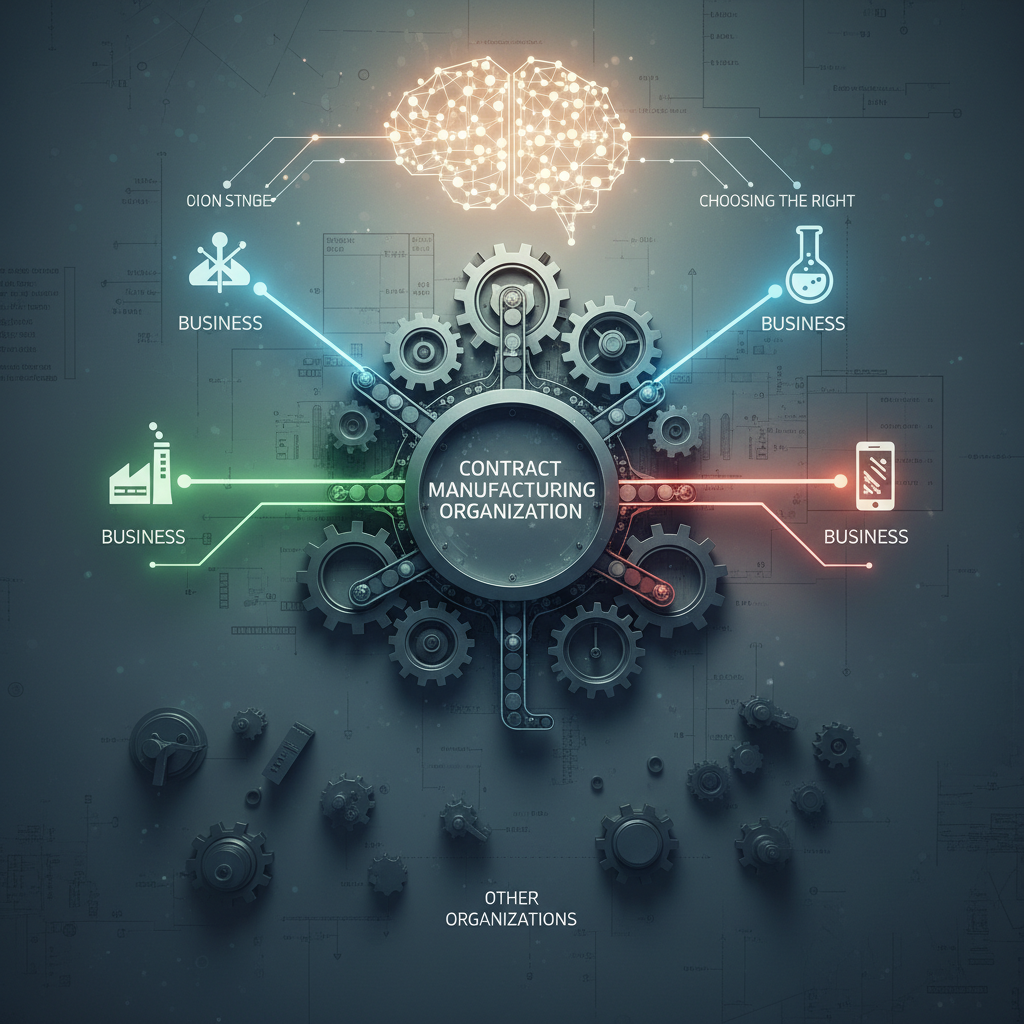

In the rapidly evolving landscape of global manufacturing, selecting the right Contract Manufacturing Organization (CMO) has become a pivotal decision for businesses striving for efficiency and competitive advantage. According to a report by Industry Perspectives, nearly 70% of companies consider their relationships with CMOs as strategic partnerships. This trend underscores the growing reliance on specialized organizations capable of providing innovative solutions tailored to specific industry needs.

Renowned industry expert Dr. Emily Schneider, a leading authority in contract manufacturing, emphasizes the significance of this decision: “Choosing the right CMO can be the difference between product success and failure, particularly in sectors where speed and precision are paramount.” As companies increasingly focus on core competencies and outsource production to enhance scalability, understanding the nuances of selecting the appropriate CMO is more critical than ever. In this article, we will explore key considerations and strategic factors that businesses should assess to ensure they partner with a CMO that aligns with their goals and growth trajectory.

When selecting a contract manufacturing organization (CMO), understanding your business needs is paramount. Begin by assessing the specific requirements of your products, including volume, complexity, and regulatory considerations. Ask yourself what capabilities are essential for your production process—whether you need specialized machinery, skilled labor, or unique manufacturing techniques. This clear self-assessment will guide you in aligning your needs with a CMO’s offerings.

**Tips:** Clearly outline your project timeline and budget to set realistic expectations. This information will help guide discussions with potential CMOs and ensure they can meet your deadlines without compromising quality. Additionally, involve key stakeholders from relevant departments, such as quality control and logistics, in the evaluation process to gather diverse insights.

Moreover, consider the location and scalability of the CMO. A partner that is nearby can reduce transportation costs and lead times, whereas a scalable operation is essential for future growth as your business evolves. Establishing clear criteria will not only refine your selection process but also foster a stronger partnership with the right CMO that can support your long-term goals.

When selecting a Contract Manufacturing Organization (CMO), evaluating their capabilities and expertise is critical for ensuring a successful partnership. Start by assessing their technical competencies and production capabilities. Look for organizations that specialize in your specific industry and have experience with similar products. This can include evaluating their technological resources, manufacturing processes, and quality control standards. A CMO with advanced machinery and up-to-date manufacturing techniques will likely be more efficient and capable of producing high-quality products.

Additionally, consider their regulatory compliance and certifications. A reputable CMO should have relevant certifications, such as ISO and GMP, which reflect their adherence to industry standards and regulations. This not only helps in maintaining quality but also ensures that the manufacturing processes align with safety and efficacy requirements. Furthermore, understanding their knowledge of market trends and ability to scale production according to your business's growth will help you gauge their expertise and long-term viability as a partner. A strong alignment in vision and capability can significantly enhance your product's success in the market.

When choosing a Contract Manufacturing Organization (CMO), evaluating cost structures and pricing models is crucial to align with your business goals. Various pricing strategies exist, such as fixed pricing, cost-plus pricing, and performance-based pricing. Understanding the pros and cons of each model can help you make informed decisions and foster a transparent relationship with your CMO.

Tips: Always request detailed quotes that break down costs into materials, labor, overhead, and profit margins. This allows you to compare different CMOs effectively and understand where adjustments can be made to fit your budget.

Additionally, assess how the CMO’s pricing evolves with changing production volumes. Some CMOs may offer competitive rates for larger orders but could become less favorable for smaller runs. It’s essential to clarify these terms upfront.

Tips: Negotiate contract terms to include options for scalability, ensuring that as your business grows, the financial implications of manufacturing remain manageable and beneficial to both parties.

When selecting a Contract Manufacturing Organization (CMO), ensuring compliance and quality standards is critical for safeguarding your brand's reputation and product integrity. According to a report by Grand View Research, the global contract manufacturing services market is projected to reach $1.3 trillion by 2028, underscoring the growing reliance on CMOs in various industries. A significant aspect of this is choosing a CMO that adheres to stringent quality assurance protocols and regulatory compliance specific to your sector, be it pharmaceuticals, food and beverage, or electronics.

To evaluate a potential CMO, businesses should assess their certifications, such as ISO 13485 for medical devices or GMP (Good Manufacturing Practices) for pharmaceuticals. A survey by the Contract Manufacturing Association indicates that 64% of companies consider regulatory compliance as their top priority when partnering with a CMO.

Additionally, it’s essential to review the organization’s track record in quality control, including metrics like defect rates and customer satisfaction scores, as these are indicative of their operational reliability. By prioritizing compliance and quality standards, businesses can significantly reduce risks and foster long-term partnerships that drive success.

Building a long-term relationship with your chosen Contract Manufacturing Organization (CMO) is crucial for the success of your business. To foster a strong partnership, clear communication is essential. This means not only conveying your needs and expectations but also actively listening to your CMO's insights and suggestions. Open dialogues about production capabilities, timelines, and potential challenges can significantly enhance collaboration and ensure that both parties are aligned in their objectives.

Moreover, trust and reliability are foundational elements of any successful partnership. When selecting a CMO, look for one that demonstrates a commitment to quality and consistent performance. Regular audits and reviews can help maintain accountability and ensure that the CMO adheres to industry standards and your specific requirements. Establishing a framework for ongoing feedback and support will allow you to address issues proactively, thereby strengthening the relationship over time and enabling both businesses to thrive together.