In the ever-evolving landscape of manufacturing, the choice of the right fabrication machine has emerged as a pivotal decision for businesses aiming to enhance efficiency and productivity. As noted by industry expert John Anderson, “Investing in the right fabrication machine is not just about cost; it’s about aligning technology with your production goals to drive growth.” With new innovations and technologies being introduced each year, understanding the myriad options available can be overwhelming for business owners.

As we look towards 2025, the need for businesses to choose the best fabrication machine tailored to their specific needs is more crucial than ever. Various factors, including production volume, material types, and technological advancements, must be taken into account to ensure the selected machine not only meets current demands but is also adaptable to future challenges. By carefully evaluating these elements, companies can make informed decisions that significantly impact their operational efficiency and bottom line.

This guide will explore key considerations for selecting the ideal fabrication machine, providing insights into the current trends and technologies that are shaping the industry. As the competitive landscape intensifies, choosing the right machinery will be a defining factor in a business's ability to thrive in the coming years.

When selecting a fabrication machine, it's crucial to first analyze your business requirements. Identify the types of materials you work with and the specific processes you need to perform, such as cutting, bending, or welding. Understanding these factors will help narrow down your options and ensure that the machines you consider are capable of handling your workload efficiently and effectively.

Additionally, consider the scale of your operations. If your business is small or growing, investing in a versatile machine that can adapt to various tasks may be beneficial. On the other hand, larger operations may require specialized machines that excel in efficiency and productivity. Also, factor in your budget and the potential return on investment; the right machine should not only meet your current needs but also accommodate future growth, keeping your production competitive in a rapidly evolving market.

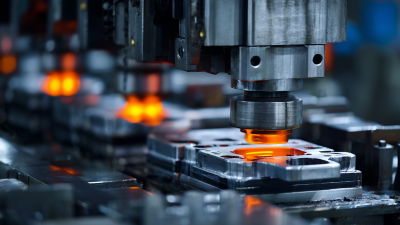

When selecting the best fabrication machine for your business, it’s essential to evaluate the various types available in the market. Fabrication machines can range from laser cutters, which have seen a 13% annual growth rate, to CNC mills that are projected to reach a global market value of $109 billion by 2027. Understanding the strengths and capabilities of these machines can significantly impact production efficiency and overall business success.

Laser cutting machines are preferred for their precision and speed, making them ideal for complex designs in metal and non-metal materials. On the other hand, CNC milling machines are renowned for their versatility and ability to handle a variety of materials. A recent survey indicated that 45% of manufacturers chose CNC technology for its ability to increase throughput and reduce waste, emphasizing the importance of aligning the machine's capabilities with specific manufacturing goals.

By comprehensively assessing the available options, businesses can invest in fabrication machines that best match their operational requirements and drive growth in their respective sectors.

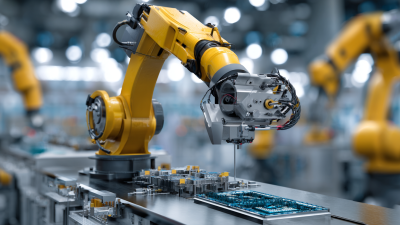

When choosing the best fabrication machine for your business needs, it's essential to focus on key features that will directly impact your operations. One of the most critical aspects is the machine's adaptability to various materials and production processes. A versatile fabrication machine can handle different types of materials, which allows for greater flexibility in manufacturing and can cater to diverse project requirements.

Additionally, consider the automation capabilities of the machine. Advanced technology, such as automated controls and integration with digital systems, can significantly enhance productivity and efficiency. Machines that incorporate smart technologies enable predictive maintenance, minimizing downtime and reducing operational costs.

Tips:

Look for machines with a user-friendly interface that simplifies operation and training for your staff. Investing in equipment with robust customer support and maintenance options is equally important to ensure long-term reliability. Lastly, assess the machine's scalability potential to accommodate future growth in your business, ensuring that it continues to meet your evolving needs.

When considering the purchase of fabrication machines, conducting a thorough cost-benefit analysis is essential for making an informed decision. This process involves evaluating both the initial investment and the long-term operational costs, including maintenance, training, and potential downtime. By quantifying these factors, businesses can determine the return on investment (ROI) that different machines offer. For instance, a more expensive machine might increase production speed and efficiency, ultimately leading to higher revenue and reduced labor costs over time.

Additionally, it is crucial to factor in the specific needs of your business. Different fabrication machines come with varying functionalities, and selecting one that aligns with your production requirements can enhance overall productivity. Understanding the market trends and technological advancements in fabrication can also guide your choice. Investing in a versatile, high-quality machine may present higher upfront costs but can result in substantial savings and increased competitiveness in the long run. By weighing these aspects carefully, businesses can choose the best fabrication machines that will provide lasting value and support future growth.

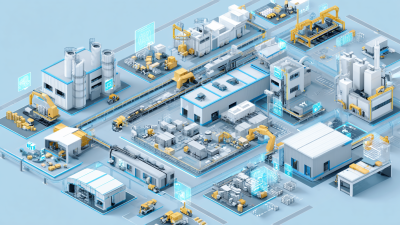

As businesses look towards 2025, future-proofing fabrication choices has become increasingly essential. Trends such as automation, digital integration, and sustainability are key factors driving the evolution of fabrication machines. According to a report by MarketsandMarkets, the global market for advanced manufacturing technologies is projected to reach $400 billion by 2025, demonstrating a strong shift towards adopting intelligent solutions in fabrication processes.

When selecting a fabrication machine, consider the incorporation of Industry 4.0 principles, which emphasize connectivity and data exchange. Implementing machines that offer real-time monitoring and predictive maintenance can not only enhance efficiency but also reduce downtime. For instance, a study by McKinsey indicates that companies embracing digital technologies can increase their productivity by up to 30%.

**Tips:** Prioritize machines with IoT capabilities to ensure seamless data flow and analysis. Additionally, assess your sustainability goals; machines that use less energy and produce minimal waste will not only help the environment but may also qualify your business for tax incentives. Finally, always evaluate the long-term service and support options available with potential suppliers to avoid costly disruptions in the future.