Choosing the right steel fabrication machinery can significantly impact production efficiency and quality. In a competitive market, selecting the appropriate equipment is crucial. According to a recent report by MarketsandMarkets, the steel fabrication machinery market is expected to reach USD 22.5 billion by 2025, with a compound annual growth rate of 6.5%. This growth highlights the increasing demand for advanced machinery in the industry.

Expert James Whitmore, a leading figure in steel fabrication technology, emphasizes, "Selecting the right machinery can make or break your business." His insight underscores the importance of evaluation before purchasing. Fabricators must consider factors like operational needs, production volume, and machine versatility. Yet, many companies often overlook these elements, leading to costly mistakes in equipment investment.

While efficiency is paramount, evaluating the long-term benefits of steel fabrication machinery requires reflection. Companies should not only focus on immediate results but also the machine's adaptability to future demands. In the evolving landscape of manufacturing, this foresight can distinguish successful businesses from those that struggle. Making informed choices in steel fabrication machinery is essential for sustainable growth.

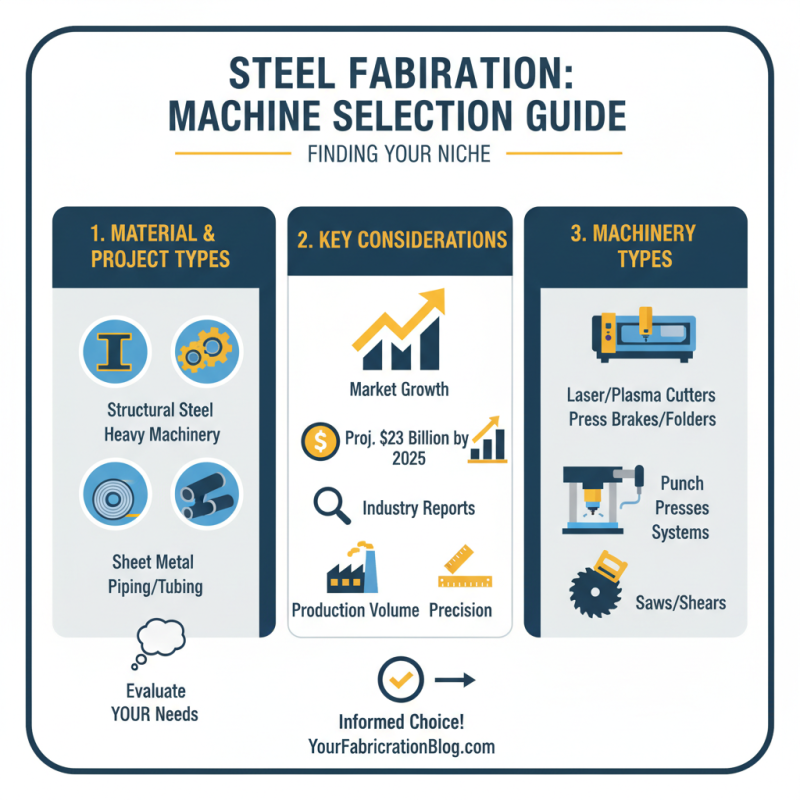

Understanding your steel fabrication needs is crucial in selecting the right machinery. Start by evaluating the types of materials and projects you typically handle. According to industry reports, the steel fabrication market is projected to reach $23 billion by 2025. So, knowing your niche is essential.

Different projects require various machinery. For example, if you mainly work with heavy steel beams, consider heavy-duty machinery that can handle this weight. For lighter projects, precision equipment may be more suitable. Tips: Assess your workload regularly. What has been working? What hasn’t? Adaptability is key in a changing market.

Another factor to consider is the level of automation your shop needs. Studies indicate that automation can increase efficiency by up to 30%. Yet, investing in high-tech machinery without proper training can lead to costly mistakes. Tips: Monitor your team's skill levels. Regular training can improve productivity and reduce waste. Reflect on your current capabilities to ensure that your machinery meets both current and future demands.

When exploring steel fabrication machinery, you may encounter several types. Each type serves a unique purpose in the fabrication process. For instance, cutting machines are common. They can be used for plasma cutting, laser cutting, or waterjet cutting. These machines vary in precision and can handle various thicknesses of steel.

Bending machines are another critical component. They can shape steel into specific angles. Press brakes are often used for this. They apply pressure to bend the material accurately. However, selecting the right bending machine can be challenging. You need to consider capacity and the range of applications.

Welding machines are vital as well. They join metal parts together, ensuring structural integrity. Different welding techniques have their pros and cons. TIG and MIG welding offer different levels of control and strength. Understanding your project requirements is essential for making an informed decision. The choice depends on skill level and the specific demands of your work.

When selecting steel fabrication machinery, key features are vital. Understanding the types of machines available is essential. For instance, a recent market analysis revealed that around 45% of businesses prioritize automation capabilities. Automation can enhance efficiency but might increase initial costs. It's crucial to balance these factors based on your operational scale.

Durability is another important aspect. Machinery should withstand heavy use. Research shows that nearly 30% of downtime in fabrication is due to equipment failure. Consider the materials used in the machinery. Steel components usually last longer but can be more expensive. Your choice should reflect not only current needs but future demands.

Ease of maintenance is often overlooked. Machines requiring specialized tools or skills can cause delays. A report indicated that 25% of operators faced challenges with machine upkeep. Simplicity in design can minimize these issues. Always assess the support available for the machinery too. A good warranty and service agreement can alleviate potential pain points. These elements can significantly impact your overall efficiency and productivity.

This chart illustrates the key features to consider when selecting steel fabrication machinery. Each feature is rated on a scale of 1 to 10, providing a visual comparison of their importance and effectiveness in machinery selection.

When choosing steel fabrication machinery, budget and cost-effectiveness are crucial. Determine your budget based on your production needs. This will help you avoid overspending. Consider both initial costs and long-term expenses. Maintenance and operational costs can add up quickly.

Tips: Research different types of machines. Look for options that save energy and reduce waste. These can offer savings over time. Sometimes cheaper machines may not provide the efficiency you need, leading to higher costs.

Evaluate the return on investment (ROI) of your choices. Think about how quickly the machinery can pay for itself through increased productivity. It's essential to factor in these elements. However, don't forget to reconsider the quality and durability of the machinery. A cheaper purchase isn't always better. It’s important to achieve a balance between cost and performance.

| Machinery Type | Initial Cost ($) | Operating Cost/Month ($) | Maintenance Cost/Year ($) | Production Efficiency (Units/Hour) | Return on Investment (Years) |

|---|---|---|---|---|---|

| Laser Cutting Machine | 40,000 | 1,200 | 2,500 | 50 | 3.5 |

| CNC Machining Center | 60,000 | 1,500 | 3,000 | 40 | 4.0 |

| Press Brake | 30,000 | 800 | 1,500 | 30 | 5.0 |

| Shearing Machine | 25,000 | 700 | 1,000 | 35 | 3.0 |

When selecting steel fabrication machinery, evaluating supplier reputation is crucial. A reliable supplier can significantly impact productivity and quality. A 2022 survey revealed that 72% of manufacturers prioritize supplier reputation when making purchasing decisions. Negative reviews often stem from poor customer service. Companies should beware of suppliers that lack transparency.

Consider support services. A recent industry report indicates that 65% of firms experienced downtime due to equipment issues. Quick access to support can mitigate these problems. Suppliers offering robust training programs enhance the integration process. Many companies overlook this aspect and suffer later due to inefficiencies.

Additionally, examine the supplier’s experience in the market. Providers with a long-standing presence often have better insights into evolving technologies. However, newer entrants may bring innovative solutions. Balance is essential. Relying solely on age can lead to missed opportunities for innovation. Take time to analyze various factors. Each decision counts in the competitive landscape of steel fabrication.