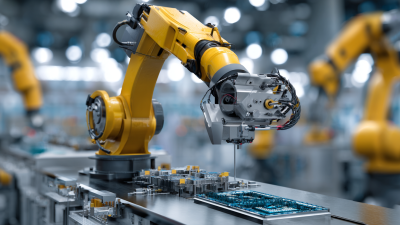

In today’s competitive business landscape, companies are continually seeking innovative strategies to enhance growth and scalability. One such strategy gaining traction is contract manufacturing, a method that allows businesses to leverage specialized expertise and production capabilities without the need for substantial investments in infrastructure. By outsourcing the manufacturing process to third-party experts, organizations can focus on their core competencies, streamline operations, and reduce operational costs.

Contract manufacturing presents a multitude of advantages that align with business growth objectives. It offers flexibility in production capacity, enabling companies to respond quickly to market demands and improve time-to-market for new products. Additionally, partnering with established manufacturers can lead to enhanced quality control and access to advanced technology, ensuring that products meet industry standards consistently. As businesses navigate the complexities of scaling operations, contract manufacturing emerges as a viable solution to address these challenges while fostering innovation and efficiency.

Contract manufacturing is a production outsourcing strategy where a business hires an external company to produce its products. This approach allows businesses to leverage the expertise, facilities, and resources of specialized manufacturers, enhancing efficiency and flexibility in the supply chain. By utilizing contract manufacturers, companies can focus on their core competencies, such as product design and marketing, while leaving the complexities of production to experts equipped with advanced technologies and processes.

One of the primary advantages of contract manufacturing is cost-effectiveness. It eliminates the necessity for significant capital investment in manufacturing facilities, machinery, and labor, allowing businesses, especially startups and small enterprises, to allocate their resources more effectively. Moreover, contract manufacturers are often located in regions with lower production costs, which can result in substantial savings. Additionally, this model facilitates quicker time-to-market, as businesses can scale their production up or down based on demand with minimal lead time, thus responding promptly to market changes and customer needs.

Contract manufacturing has become an essential strategy for businesses aiming to scale operations efficiently while minimizing costs. According to a report by the Industry Association, approximately 70% of companies that leverage contract manufacturing experience significant cost savings—an average of 20-40% in production costs. This reduction is largely attributed to the ability to capitalize on the specialized capabilities and established infrastructure of contract manufacturers, which often have modern technology and skilled labor that smaller businesses may lack.

Additionally, choosing contract manufacturing provides flexibility and quicker access to market. A study by Market Research Future highlighted that the global contract manufacturing market is projected to grow at a CAGR of over 8% from 2021 to 2026. This growth reflects businesses' increasing reliance on outsourced production to adapt swiftly to market demands and consumer trends. By partnering with contract manufacturers, companies can focus on their core competencies such as product development and marketing, while leaving the complexities of production to experts in the field. This strategic shift not only enhances operational efficiency but also accelerates product launch timelines, ultimately driving business growth.

| Benefit | Description | Impact on Business |

|---|---|---|

| Cost Efficiency | Reduces manufacturing costs through economies of scale. | Increased profitability and lower product prices. |

| Access to Expertise | Leverages the specialized knowledge of manufacturing partners. | Improved product quality and innovation. |

| Scalability | Easily adjust production levels based on market demand. | Better alignment with market opportunities. |

| Faster Time to Market | Streamlined manufacturing processes to launch products quickly. | Increased competitive advantage. |

| Focus on Core Business | Allows companies to concentrate on strategic initiatives. | Enhanced operational efficiency and resource allocation. |

When selecting a contract manufacturer, several critical factors must be considered to ensure alignment with your business growth objectives. One of the primary considerations is the manufacturer's expertise and specialization in your industry. According to a 2021 report by Research and Markets, the global contract manufacturing market is projected to grow from $112.57 billion in 2021 to $155.89 billion by 2026, underscoring the increasing reliance businesses have on these partnerships. Companies should evaluate the manufacturer's technical capabilities and experience with similar products to ensure they can meet both quality and compliance standards.

Another important factor is the manufacturer's capacity and scalability. As businesses experience growth, their production needs often change. A recent study published by Deloitte emphasizes that a flexible manufacturing partner can significantly enhance a company’s ability to scale, allowing for quick adjustments without the need for substantial capital investment. This ensures that as demand fluctuates, the contract manufacturer can adapt, maintaining efficiency and quality. Additionally, geographical location can impact lead times and shipping costs, making it essential to consider both local and overseas options depending on your strategic needs.

Quality control serves as a vital pillar in the success of contract manufacturing, directly impacting product consistency and reliability. By implementing robust quality control measures, manufacturers ensure that every product meets established standards before reaching the market. This not only enhances customer satisfaction but also fosters long-term brand loyalty. A systematic approach to quality control involves rigorous testing, regular audits, and adherence to industry regulations, allowing businesses to mitigate risks associated with defective products.

Moreover, effective quality control within contract manufacturing facilitates smoother communication between parties. By establishing clear quality benchmarks, manufacturers and clients can align their expectations and minimize misunderstandings. Regular feedback loops and transparent reporting mechanisms contribute to a collaborative environment, ensuring that any potential issues are addressed promptly. This proactive stance not only enhances operational efficiency but also supports continuous improvement, thus empowering businesses to adapt quickly to market demands and maintain a competitive edge.

Contract manufacturing offers a strategic advantage for businesses aiming to enhance scalability and flexibility in their operations. By partnering with a contract manufacturer, companies can rapidly adjust their production capabilities to meet changing market demands without the burden of managing large-scale manufacturing facilities. This adaptability allows businesses to scale up production during peak seasons or reduce it when demand wanes, all while maintaining quality and efficiency. Additionally, with contract manufacturers often having access to advanced technologies and processes, businesses can remain competitive by leveraging expertise that might not be feasible to develop in-house.

Flexibility is another key benefit of contract manufacturing. It enables companies to introduce new products or modify existing ones quickly, thus responding effectively to consumer trends and preferences. This dynamic approach reduces the risks associated with product launches and allows for iterative improvements based on real-time feedback. Furthermore, by outsourcing production, businesses can focus on their core competencies, such as innovation and marketing, while leaving the complexities of manufacturing logistics to their partners. Ultimately, this blend of scalability and flexibility paves the way for sustainable growth and a more resilient business model in an ever-evolving marketplace.