Machine fabrication is a vital process in modern manufacturing. It involves using machines to create parts and products, shaping the industries we know today. Effective techniques can improve production speed and accuracy. These techniques also reduce waste, making them essential in a competitive market.

However, achieving efficiency in machine fabrication is not always straightforward. Many factors can impact the outcome. Selecting the right materials, for example, can influence the final product's strength and durability. Additionally, improper machine settings can lead to defects. Thus, attention to detail is crucial. Mistakes can be costly, both in time and resources.

In this guide, we explore practical tips to enhance your machine fabrication process. From optimizing your equipment setup to refining your workflow, we aim to provide value. Each technique is a building block toward greater efficiency. Reflection on past experiences can lead to significant improvements in machine fabrication practices.

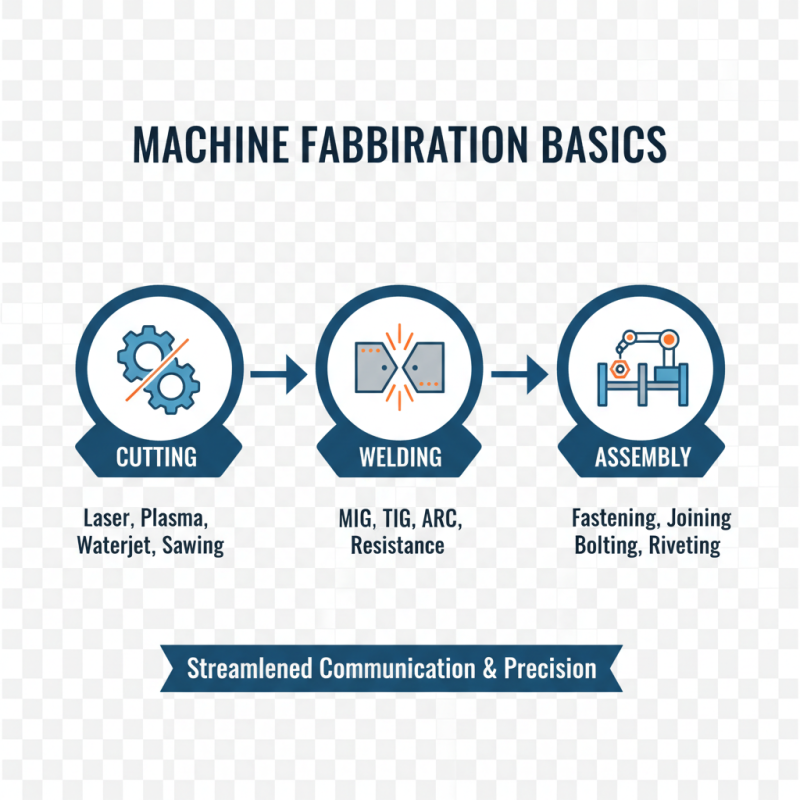

Machine fabrication is a complex process. It requires a solid understanding of key concepts and terminology. Familiarity with these terms helps streamline communication among professionals. The basics include elements like cutting, welding, and assembly. Each technique has its own terminology, which can sometimes be daunting.

Cutting involves various methods, such as laser and plasma, each with distinct features. Welding, on the other hand, connects materials. Techniques like MIG and TIG welding serve different purposes. Knowing these can impact the quality of the final product. The challenge lies in selecting the right method for the task. Misunderstanding terms can lead to mistakes.

Assembly is the final stage of fabrication. It requires precise alignment and fitting of parts. Even minor errors can lead to significant issues. Machine fabrication also involves considerations of material properties. Sometimes, the right material isn’t used for the job. This oversight can lead to inefficiencies. Therefore, grasping basic terminology is more than just learning words; it's essential for effective fabrication.

Effective machine fabrication requires the right tools and equipment. Whether you are welding, cutting, or assembling, each task demands specific devices. A reliable welding machine is essential to produce strong joints. Proper selection and maintenance ensure performance. Don't underestimate the importance of a good workbench. It provides stability for precision tasks.

Beyond the fundamental tools, safety gear is non-negotiable. Gloves, goggles, and respirators protect operators from hazards. Investing in quality safety equipment often pays off. You might face challenges with tool performance. Regular checks can reveal issues before they escalate. It's a reflection of how well you manage your workspace.

Consider the importance of storage solutions, too. Disorganized tools lead to delays. Creating an efficient system might require some trial and error. Sometimes, the best ideas come from mistakes. Evaluate your workspace layout regularly. Improvement is a continuous journey in machine fabrication. Every small enhancement contributes greatly to overall efficiency.

When it comes to machine fabrication, understanding the common techniques is crucial. The first technique is CNC machining. This method allows for precision in parts production. According to industry data, CNC machining improves accuracy by up to 80%. This method is vital for achieving tight tolerances in various applications.

Another effective technique is welding. It plays a key role in joining materials. However, not all welds are created equal. Inaccurate welds lead to weaknesses in structures. Data shows that about 30% of welding jobs fail due to poor technique. Regularly reviewing welds and practicing gently can improve results significantly.

For better outcomes, a few tips can be applied. Invest in quality tools, as they make a difference. Ensure that the workspace is clean and organized, which minimizes errors. Don’t underestimate the importance of training. Skilled workers produce better outcomes. Mistakes happen, but reflection on them leads to progress. Emphasizing continuous improvement boosts overall success in fabrication projects.

| Technique | Description | Materials Used | Key Benefits |

|---|---|---|---|

| Welding | Joining metals through heat to form a strong bond. | Steel, Aluminum, Stainless Steel | High strength, durability, and versatility. |

| Laser Cutting | Using laser beams to cut materials with high precision. | Steel, Plastic, Wood | Precision, minimal waste, and flexibility in design. |

| CNC Machining | Computer-controlled machining for high accuracy. | Metals, Plastics, Composites | High repeatability, complex geometries, and scalability. |

| Bending | Deforming metal to create angles and shapes. | Aluminum, Steel, Copper | Cost-effective, quick adjustments, and material efficiency. |

| Finishing | Applying coatings or treatments to enhance surface properties. | Paint, Powder Coating, Anodizing | Improved aesthetics, corrosion resistance, and increased durability. |

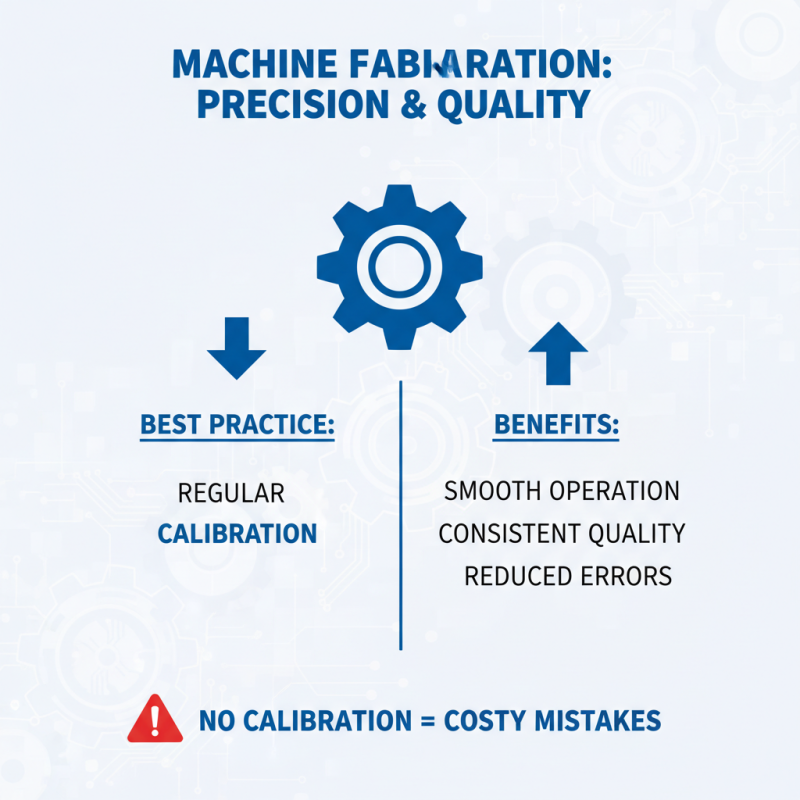

When it comes to machine fabrication, precision and quality are critical. One best practice is to ensure that all machines are regularly calibrated. This keeps the equipment running smoothly. Calibration helps to maintain consistent production quality. If machines are not calibrated, errors may occur. This can lead to costly mistakes.

Another essential tip is to utilize the right tooling. Choosing the proper tools for each specific task is vital. Every tool has its strengths and weaknesses. A wrong tool can cause increased wear and tear on both the tool and machine. Keeping an eye on tool conditions can save time and money. Replace tools as needed to maintain quality.

Finally, regular training for the staff is important. Skilled workers can better handle complex tasks. They are also more likely to follow proper procedures. Mistakes happen, but they can be minimized with experience and knowledge. Fostering an environment of continuous improvement will promote better practices. Continuous reflection on the process keeps the focus on quality.

Innovations in machine fabrication are shaping the future of manufacturing. Recent reports indicate that the global machine fabrication market is projected to reach $200 billion by 2025. This growth reflects advancements in automation and precision engineering, pushing boundaries in efficiency and product quality. However, many companies still struggle to integrate these new technologies effectively.

3D printing and additive manufacturing are leading trends. This technology reduces material waste and allows for complex designs. A survey from the Society of Manufacturing Engineers found that 61% of companies are exploring additive techniques. Despite its benefits, challenges remain. Not all materials are suited for 3D processes, and printing speed can be a bottleneck. Businesses must navigate these limitations carefully.

Furthermore, Industry 4.0 is transforming how machines communicate. Smart machines collect data in real-time. This connectivity can enhance performance and predict maintenance needs. However, many manufacturers lack the IT infrastructure for effective implementation. A 2023 report highlighted that only 35% of firms have fully digitized their operations. This gap must be addressed for the industry to realize its full potential.