Efficient fabrication of machined steel parts is crucial in today's manufacturing landscape. This process combines precision, speed, and cost-effectiveness. Companies strive to produce parts that meet strict quality standards. Yet, challenges often arise, leading to inefficiencies.

Machined steel parts require accurate measurements and skilled labor. However, human error can compromise quality. Tools can wear down during production, resulting in defects. Regular maintenance is essential, but sometimes neglected. This neglect highlights the need for better process management.

Creating a robust fabrication approach also involves selecting the right materials. The balance between cost and quality can be tricky. Misjudgments can lead to wastage. In an industry that values efficiency, every misstep counts. Companies must continuously reflect and improve their methods to achieve optimal results with machined steel parts. Addressing these factors is key to advancing manufacturing practices.

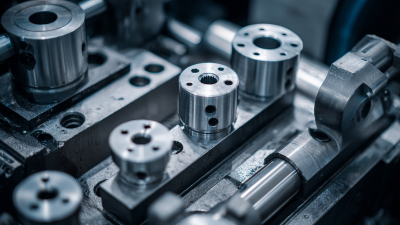

Machined steel parts are pivotal in many industries. Understanding the basics of their fabrication can lead to efficiency improvements. The fabrication process involves multiple steps. Each step has its challenges. Moreover, precision is key. A report by the National Institute of Standards and Technology states that errors in machining can lead to significant waste and rework. Addressing these issues reduces costs.

Material selection impacts the final product. High-quality steel leads to better outcomes. The American Society for Metals notes that nearly 40% of machining failures are due to material flaws. Choosing the right type of steel is crucial. Also, tooling must match the steel grade. Improper tools lead to accelerated wear. This not only hinders productivity but also affects precision.

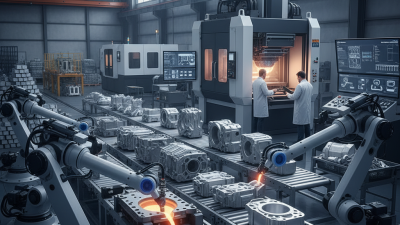

Technology plays a role in efficiency. Automation in machining is on the rise. It’s reported that automated systems can increase productivity by up to 30%. However, reliance on technology requires constant monitoring. Mistakes can happen quickly. Failure to adapt may result in production delays. Such reflections are vital in an ever-evolving industry like machining.

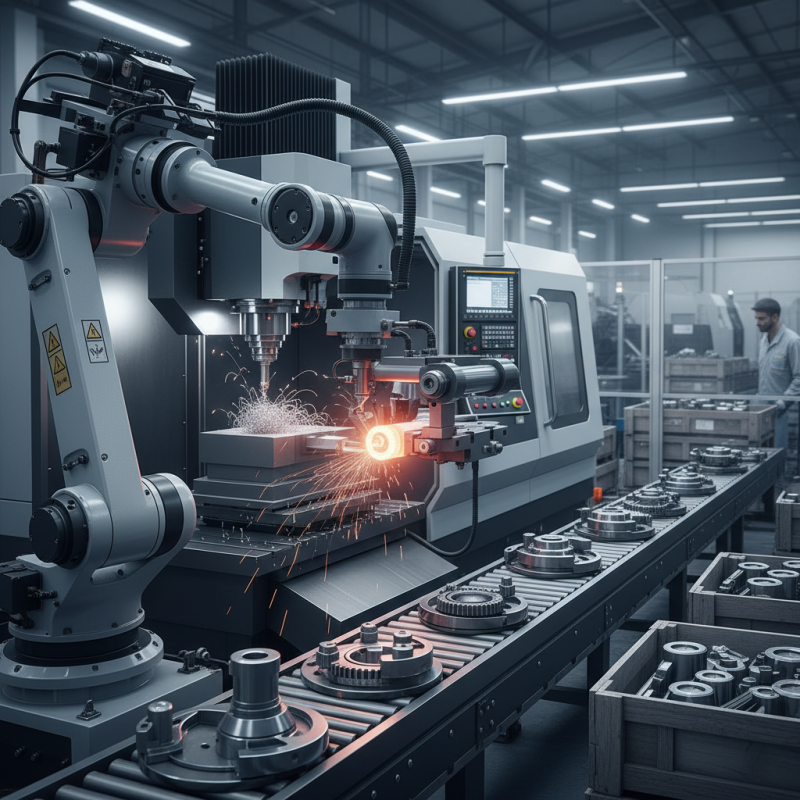

Machining steel parts efficiently requires the right tools and equipment. Investing in high-quality machinery can save time and improve accuracy. Key machines include lathes, milling machines, and CNC machines. Each plays a vital role in shaping and finishing steel components.

Tips: Regular maintenance is crucial. A well-maintained machine operates smoother and lasts longer. Check for wear and tear often. Replace worn parts before they cause bigger issues.

Cutting tools are another important consideration. Use appropriate materials for your projects. Different steels require specific cutting edges. Don't overlook the significance of tool geometry. Understanding it can lead to significant efficiency gains.

Tip: Utilize coolant during machining. This reduces heat build-up and improves tool life. Cooling also enhances surface finish. Keep an eye on coolant levels for optimal performance.

Reflect on your setup frequently. You may find areas for improvement. Efficiency often comes from small adjustments. Analyze your production flow and make necessary changes. Adjustments could mean the difference between good and great results.

Precision in steel machining is crucial for achieving high-quality components. According to a report by the National Institute of Standards and Technology, machining processes contribute to approximately 20% of the total manufacturing costs in the metalworking industry. Therefore, enhancing precision can significantly improve efficiency and reduce expenses.

One key technique is the use of advanced cutting tools. PVD-coated tools can extend tool life, reducing downtime. However, improper tool selection can lead to increased wear and tear. It's important to analyze the material being machined. For instance, machining hardened steel requires different tools than soft steel. Overlooking this can result in poor surface finishes.

Furthermore, adopting CNC technology can enhance precision. Modern CNC machines offer tighter tolerances, often around ±0.001 inches. Yet, frequent calibration is required. Neglecting regular checks can cause deviations over time. Incorporating simulation software can also minimize errors. It allows for virtual testing, reducing waste and rework. However, not all teams are well-trained in utilizing these tools effectively. Failure to invest in staff training can hinder potential gains.

In the quest for efficient fabrication, focusing on precision through these methods is essential, yet challenges remain. Emphasizing continuous improvement is vital in a rapidly evolving industry.

| Technique | Description | Benefits | Common Application |

|---|---|---|---|

| CNC Machining | Utilizing Computer Numerical Control for precise automated machining. | High precision, repeatability, reduces human error. | Complex geometry parts. |

| Tool Path Optimization | Strategically planning the tool movement to reduce machining time. | Increases efficiency, lowers tool wear. | High-volume production runs. |

| Material Selection | Choosing the right steel grade for specific applications. | Enhanced performance, durability, and cost-effectiveness. | Automotive and aerospace components. |

| Coolant Management | Using coolants efficiently to control temperature during machining. | Reduces thermal distortion, prolongs tool life. | Any machining operation. |

| Quality Control | Implementing inspections during and after machining processes. | Ensures high precision and compliance with specifications. | Final assembly operations. |

Efficient fabrication of machined steel parts is critical in modern manufacturing. Reducing waste is a priority. Start by optimizing tool paths during the machining process. This can significantly minimize excess material. Using software that simulates machining can help identify areas for improvement. Regular maintenance of machinery also plays a role. A worn tool leads to more scrap and less efficiency.

Another essential practice is proper training for the workforce. Skilled operators can recognize issues quickly and adjust processes in real-time. Training programs should emphasize efficiency techniques and waste reduction tactics. Regular feedback sessions can help team members share their challenges. This fosters a culture of continuous improvement.

On a different note, it’s important to reflect on the manufacturing layout. Sometimes, the physical arrangement can lead to inefficiencies. Equipment that is too far apart slows down production. Observations can reveal bottlenecks that aren't initially obvious. Small changes in layout can create a more streamlined operation. Embracing these practices creates a pathway toward a sustainable and efficient fabrication process.

The future of machining technology for steel parts is promising yet complex. A 2023 report from the International Society for Precision Engineering indicated that automation in machining could improve efficiency by up to 30%. This transition towards automation opens doors, but it also raises questions about job displacement and the need for re-skilling workers. The rise of CNC technology has transformed traditional methods, but it’s not without challenges. Many companies face high initial investments that can restrict adoption.

In addition, the integration of AI in machining processes is on the rise. According to a recent industry forecast, AI-driven machines can reduce waste by nearly 25% while optimizing the machining cycle. However, the reliance on AI brings its own set of issues. Data security and system malfunctions can lead to costly downtime. As manufacturers eagerly adopt these technologies, some have reported difficulties in maintaining quality control, underscoring the need to refine these new methods continually.

Furthermore, 3D printing is emerging as a key player in fabricating steel parts, especially in prototyping. A recent study predicted a growth of 20% in the 3D printing market by 2026. While it offers advantages like reduced lead times, inconsistency in material properties is a concern. Balancing speed and quality remains a critical challenge for the industry, pushing engineers to innovate constantly.