Choosing the right steel fabrication machinery is a critical decision that can significantly impact the efficiency and productivity of your operations. With an array of options available, from cutting and welding devices to CNC machines, it becomes essential to understand the key factors that influence your buying choices. This guide aims to provide you with the top ten essential tips for selecting steel fabrication machinery that not only meets your specific needs but also aligns with your budget and operational goals.

In a market characterized by rapid technological advancements and increasing competition, investing in the appropriate steel fabrication machinery can enhance your manufacturing capabilities and lead to higher-quality output. By considering aspects such as the machinery's versatility, production capacity, and compatibility with your existing systems, you can make a more informed decision. As we explore the vital elements to assess when purchasing steel fabrication machinery, you will be equipped with the knowledge to optimize your investment and drive your business forward.

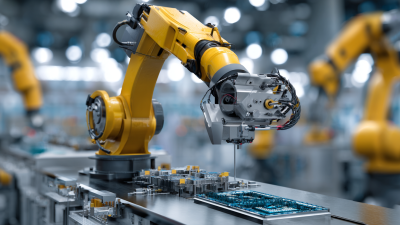

When it comes to selecting steel fabrication machinery, understanding your specific fabrication needs is crucial. The first step is to assess the types of projects you will be undertaking. Are you focusing on heavy-duty structural components, or are you looking at more intricate designs for lighter applications? Analyzing the volume and variety of your projects will help determine the capabilities you require from your machinery. For instance, high-volume production may necessitate automated systems, while custom projects might require more versatile and adaptable equipment.

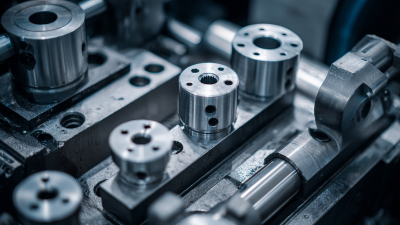

Additionally, evaluating the materials you will be working with can influence your choices significantly. Different types of steel, such as stainless or mild steel, may require distinct machinery specifications. Furthermore, consider the thickness and dimension of the materials, as these factors can impact the type of cutting, bending, or welding equipment you need. By thoroughly understanding your fabrication needs, you can streamline your decision-making process and invest in machinery that truly enhances your production efficiency and meets your operational demands.

When evaluating different types of steel fabrication machinery, it’s crucial to understand the specific needs of your operations. The diversity of steel fabrication processes—from cutting, bending, welding to finishing—requires tailored machinery suited to each method. For instance, laser cutting machines are known for precision and efficiency, making them ideal for intricate designs, while plasma cutters might be more suitable for heavier materials where speed is essential.

Additionally, consider the scale of your production. If your operation demands high-volume output, investing in automated machinery can significantly enhance productivity and reduce labor costs. Conversely, for smaller tasks or specialized projects, semi-automatic or manual machines may provide the necessary control and flexibility. It’s also important to assess the upgrade options and compatibility with existing systems, ensuring seamless integration as your business evolves.

By carefully analyzing the strengths and capabilities of various machinery types, you can make an informed decision that aligns with your specific fabrication goals.

When selecting steel fabrication machinery, understanding the key features is crucial for making an informed decision. One important aspect to consider is the machinery's versatility. Equipment that can handle a variety of processes—such as cutting, bending, and welding—offers greater flexibility, allowing you to efficiently tackle different projects without needing multiple machines. Additionally, look for machines with adjustable settings to accommodate various material thicknesses and types, which can enhance productivity and streamline operations.

Another essential feature to evaluate is the technology and automation integrated into the machinery. Modern equipment often includes advanced software for precision control and real-time monitoring, which can significantly improve accuracy and reduce waste. Moreover, assess the ease of use and maintenance requirements. Machines that are user-friendly can minimize training time for operators, while those that are easy to maintain will contribute to increased uptime and lower overall operational costs. Ultimately, choosing equipment with these key features will lead to improved efficiency and better results in your steel fabrication projects.

When assessing the cost and budget for machinery investment in steel fabrication, it is crucial to begin with a comprehensive analysis of both initial expenses and long-term operational costs. Initial costs typically include the purchase price, shipping, installation, and any necessary modifications to existing facilities. It is essential to conduct thorough market research to understand the range of prices and identify what features are non-negotiable for your specific needs. Taking the time to compare different options can lead to significant savings and ensure that the selected machinery aligns well with operational goals.

In addition to upfront costs, potential buyers should also consider ongoing operating expenses such as maintenance, energy consumption, and labor costs. Machinery that may appear economical initially might lead to higher operating costs over time due to inefficiencies. It’s vital to factor in reliability and ease of maintenance when choosing machinery, as these aspects will impact the total cost of ownership. Moreover, investing in higher-quality machines could yield better performance, ultimately providing a better return on investment. Balancing initial costs with these ongoing expenses will help create a sustainable budget that supports both immediate and future production needs.

When it comes to selecting steel fabrication machinery, researching reputable manufacturers and suppliers is paramount. A reliable manufacturer not only guarantees the quality of machinery but also ensures after-sale services, which are crucial for maintaining operational efficiency. Start by gathering information about various manufacturers in the industry through online resources, industry directories, and trade shows. Pay attention to their years of experience, technological innovations, and customer feedback. A manufacturer with a solid track record and positive testimonials often indicates a commitment to producing high-quality machinery.

Another essential aspect to consider is the supplier's support network. Investigate whether the supplier has a responsive customer service team and accessible technical support. This can be particularly important in times of equipment failure or maintenance needs. Evaluate the supplier's logistics capabilities as well, including their reliability in delivering parts and machinery on time. An efficient supply chain can significantly reduce downtime in your operations. Ultimately, thorough research and due diligence on manufacturers and suppliers will equip you to make informed decisions that align with your specific fabrication needs.