In the rapidly evolving landscape of modern industries, the future of welding manufacturing technologies stands at the forefront of innovation and efficiency. As highlighted by the Global Welding Equipment Market report, which estimates the sector to reach $25 billion by 2025, the demand for advanced welding solutions is surging due to the increasing complexity of manufacturing processes. Moreover, with the advent of Industry 4.0 and the integration of automation and artificial intelligence, welding manufacturing is undergoing a significant transformation that promises enhanced precision and reduced operational costs. Companies are increasingly adopting robotic welding systems, which, according to a recent analysis by Allied Market Research, are projected to grow at a CAGR of over 9% between 2020 and 2027. This outlines not only the importance of adopting cutting-edge technologies in welding manufacturing but also signals a pivotal shift towards sustainable and efficient practices that can redefine production capabilities across various sectors.

The welding manufacturing sector is undergoing a transformative evolution driven by automation and robotics. As industries strive for higher efficiency and precision, integrating advanced technologies into welding processes has become essential. Robotic welding systems are now equipped with sophisticated sensors and AI capabilities, enabling them to perform complex tasks with minimal human intervention. This shift not only enhances productivity but also significantly improves the quality of welded joints.

Tips for successfully implementing automation in welding include investing in quality training for operators to understand the technology and its potential. Additionally, evaluating the compatibility of existing machinery with new robotic systems can streamline the transition. Regular maintenance and updates to software will ensure that the system runs smoothly and efficiently, adhering to the latest industry standards.

Moreover, it is vital to assess the specific needs of the manufacturing process before selecting the right automation equipment. Customizable robotic solutions can cater to various welding techniques, providing flexibility in production. By embracing these advancements, manufacturers can stay competitive and cater to the evolving demands of modern industries.

The advancement of welding technologies is significantly influenced by the development of advanced materials, which play a crucial role in enhancing both efficiency and performance in modern industries. Innovative materials such as high-strength alloys, composites, and smart materials are being integrated into welding processes, enabling stronger and more durable welds. These materials often possess superior properties such as resistance to heat, corrosion, and stress, which are essential for projects in sectors like aerospace, automotive, and construction.

Moreover, the use of advanced materials facilitates the implementation of automated and robotic welding systems, allowing for greater precision and consistency. This not only reduces production times but also minimizes the risk of defects, thereby enhancing overall productivity. As industries strive to meet stringent regulatory standards and customer demands, the synergy between advanced welding technologies and innovative materials is becoming increasingly vital. By continuously exploring and integrating these advancements, manufacturers can ensure sustainable growth and maintain a competitive edge in the evolving market.

The welding manufacturing sector is undergoing a transformative shift as industries turn to data-driven decision-making powered by Internet of Things (IoT) technologies and Big Data analytics. Recent studies, such as the report by Grand View Research, indicate that the global IoT in the welding market is expected to reach $3.15 billion by 2027, growing at a CAGR of 15.1%. This growth underscores the increasing reliance on interconnected devices that optimize welding processes, enhance precision, and minimize downtime.

By leveraging Big Data, manufacturers can analyze vast amounts of operational data in real-time, leading to more informed decision-making. For instance, according to a report by McKinsey & Company, businesses that adopt data analytics in their operations can see productivity gains of 20-30%. In welding operations, applying predictive analytics allows for better maintenance scheduling, reducing unexpected equipment failures and optimizing material usage.

This proactive approach ensures that industries are not only improving their operational efficiency but also elevating product quality by minimizing defects related to human error or machine inefficiencies. The future of welding manufacturing technologies is undoubtedly intertwined with these advancements, paving the way for smarter, more efficient operations.

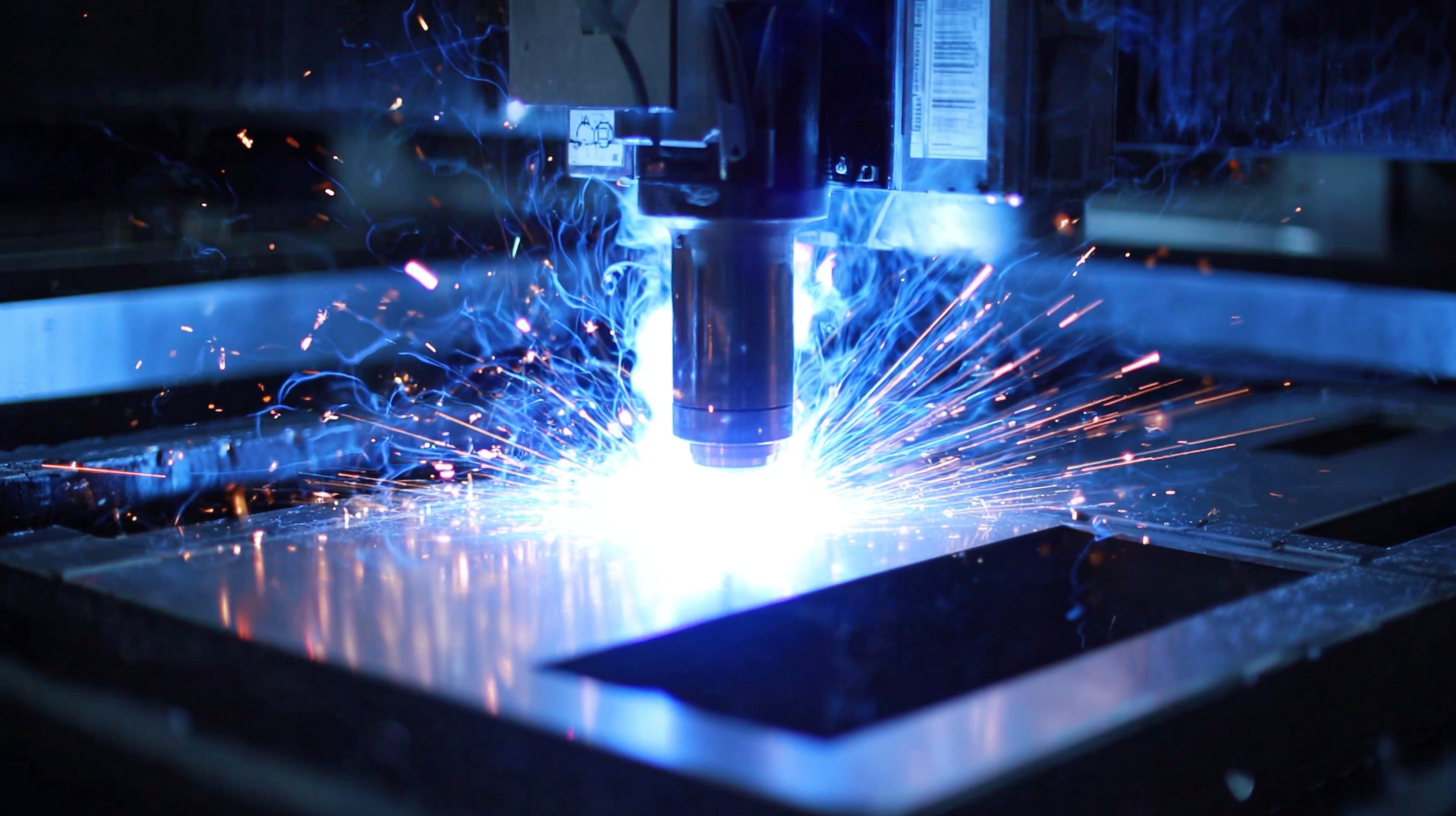

As industries evolve, the commitment to sustainability has become a driving force behind advancements in welding manufacturing technologies. The traditional welding processes, often associated with high energy consumption and emissions, are undergoing a transformation. Manufacturers are increasingly adopting eco-friendly technologies that not only reduce the environmental impact but also enhance efficiency. Innovations such as laser welding and advanced robotic systems minimize waste and energy use while improving precision and quality.

Furthermore, the integration of sustainable practices in welding encompasses the use of less harmful materials and the implementation of recycling initiatives for metal scraps. Companies are exploring greener consumables and non-toxic shielding gases, which contribute to a healthier workplace and reduce the overall carbon footprint. By prioritizing sustainability in welding operations, industries can align themselves with global environmental goals while meeting the growing demand for greener products.

This shift towards eco-friendly technologies is not just a trend; it represents a fundamental change in how welding manufacturing will shape the future.

Additive Manufacturing (AM), also known as 3D printing, has seen remarkable advancements over the past twenty years, revolutionizing traditional manufacturing methods, including welding. This technology enables the production of complex geometries and customized components through layer-by-layer fabrication, offering greater design flexibility. According to industry projections, the AM market is expected to surpass $40 billion by 2030, demonstrating its increasing adoption across various sectors, such as aerospace, biomedical, and automotive industries.

One of the key impacts of AM on traditional welding methods is the potential for enhanced efficiency and sustainability. For instance, sustainable additive manufacturing processes can significantly mitigate greenhouse gas emissions in industries like construction. Recent surveys indicate that leading additive manufacturers are prioritizing innovations that reduce environmental footprints while improving production capabilities. Moreover, the integration of high-power laser technologies in welding applications presents opportunities for precise and efficient operations, underscoring the transformative effects of AM in modern manufacturing ecosystems. As industries continue to embrace these advancements, the interplay between additive manufacturing and traditional welding practices will shape the future landscape of manufacturing technologies.

This chart illustrates the comparison of efficiency levels between traditional welding methods and additive manufacturing. The data indicates that additive manufacturing demonstrates a significantly higher efficiency rate, highlighting its potential impact on the future of welding technologies in modern industries.