In today's competitive industrial landscape, the significance of machined steel parts is paramount to enhancing efficiency and performance across manufacturing processes. According to a report by MarketsandMarkets, the global machined parts market is projected to reach USD 325.2 billion by 2026, with a compound annual growth rate (CAGR) of 8.1% from 2021 to 2026. This growth underscores the critical role that precision-engineered components play in sectors ranging from automotive to aerospace, where reliability and precision are non-negotiable. Machined steel parts are essential for achieving high tolerances and durability, which are vital for maintaining operational excellence. As manufacturers increasingly adopt advanced technologies and automation, understanding the intricacies of machined steel parts, including their design, processing, and applications, becomes crucial for staying ahead of the curve and meeting the demands of a rapidly evolving market.

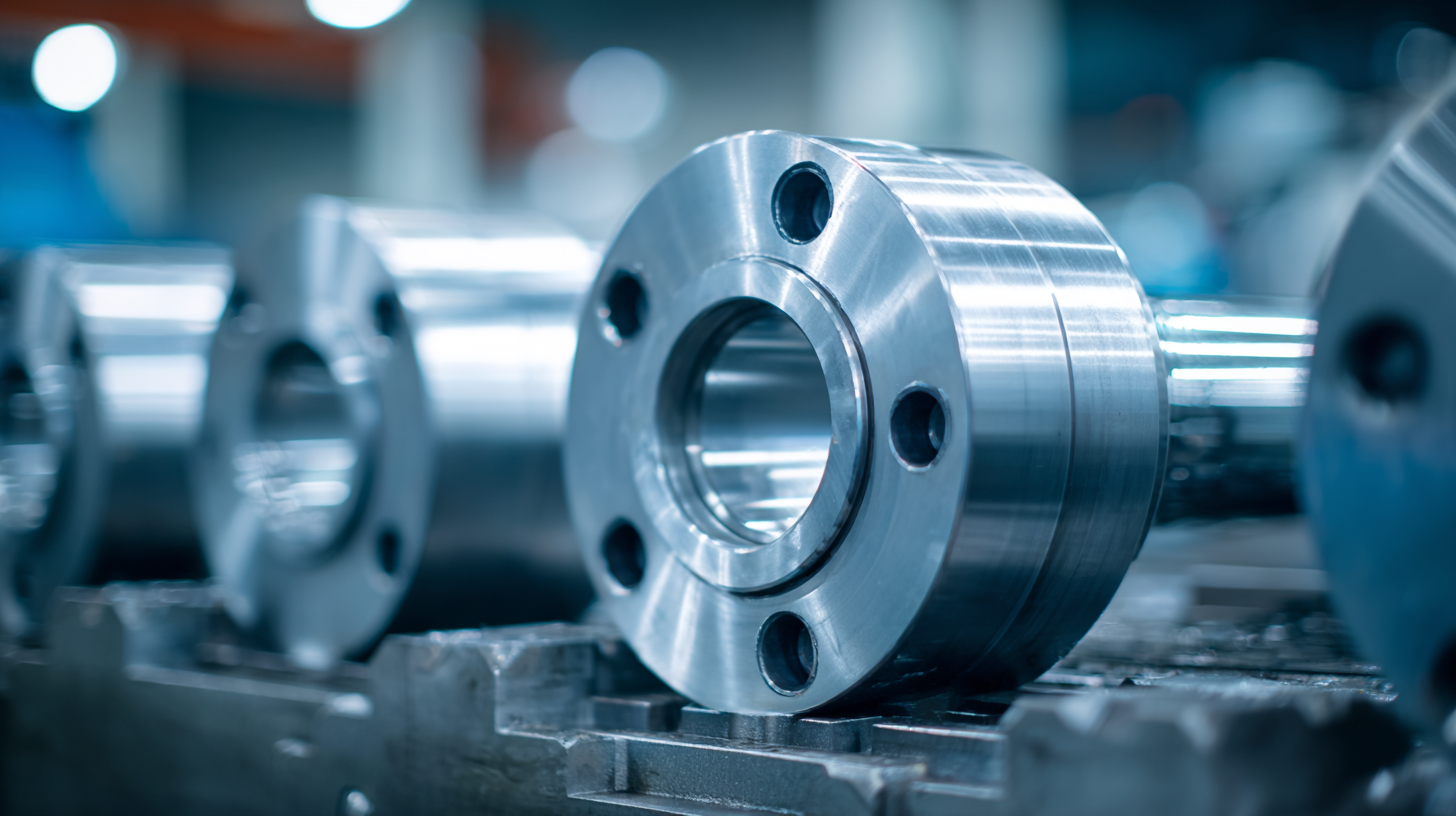

Machined steel parts play a crucial role in enhancing product durability in modern manufacturing. These components are precisely crafted to meet specific tolerances and specifications, ensuring that they can withstand high stresses and extreme conditions. The durability provided by machined steel parts translates directly into improved performance and longevity of the final products, which is essential for industries such as automotive, aerospace, and heavy machinery.

Machined steel parts play a crucial role in enhancing product durability in modern manufacturing. These components are precisely crafted to meet specific tolerances and specifications, ensuring that they can withstand high stresses and extreme conditions. The durability provided by machined steel parts translates directly into improved performance and longevity of the final products, which is essential for industries such as automotive, aerospace, and heavy machinery.

Moreover, the quality of machined steel parts significantly impacts overall manufacturing efficiency. By utilizing advanced machining techniques, manufacturers can produce components that not only enhance durability but also reduce the likelihood of failure in critical applications. This reliability leads to less downtime and lower maintenance costs, ultimately benefiting the entire manufacturing process. In summary, the incorporation of high-quality machined steel parts is pivotal in producing durable and robust products that meet the demands of today’s fast-paced industrial landscape.

Machined steel parts play a crucial role in modern manufacturing, primarily due to their cost-effectiveness compared to alternative materials. When evaluating the financial implications of using machined steel, it becomes evident that despite higher initial material costs, its durability and strength lead to lower long-term operational expenses. The longevity of machined steel components reduces the frequency of replacements, thereby minimizing downtime and maintenance costs, which is particularly important in high-volume production environments.

In contrast, while materials like plastics or aluminum may have lower upfront costs, they often fall short in durability and load-bearing capacity. These alternatives can increase the overall expenses of manufacturing processes due to their tendency to wear down more quickly or require more frequent replacement. Additionally, the performance reliability of machined steel parts ensures consistent quality, reducing the risk of production errors and enhancing product integrity. Consequently, manufacturers are increasingly recognizing that investing in machined steel parts ultimately translates to better economic viability and operational efficiency in the long run.

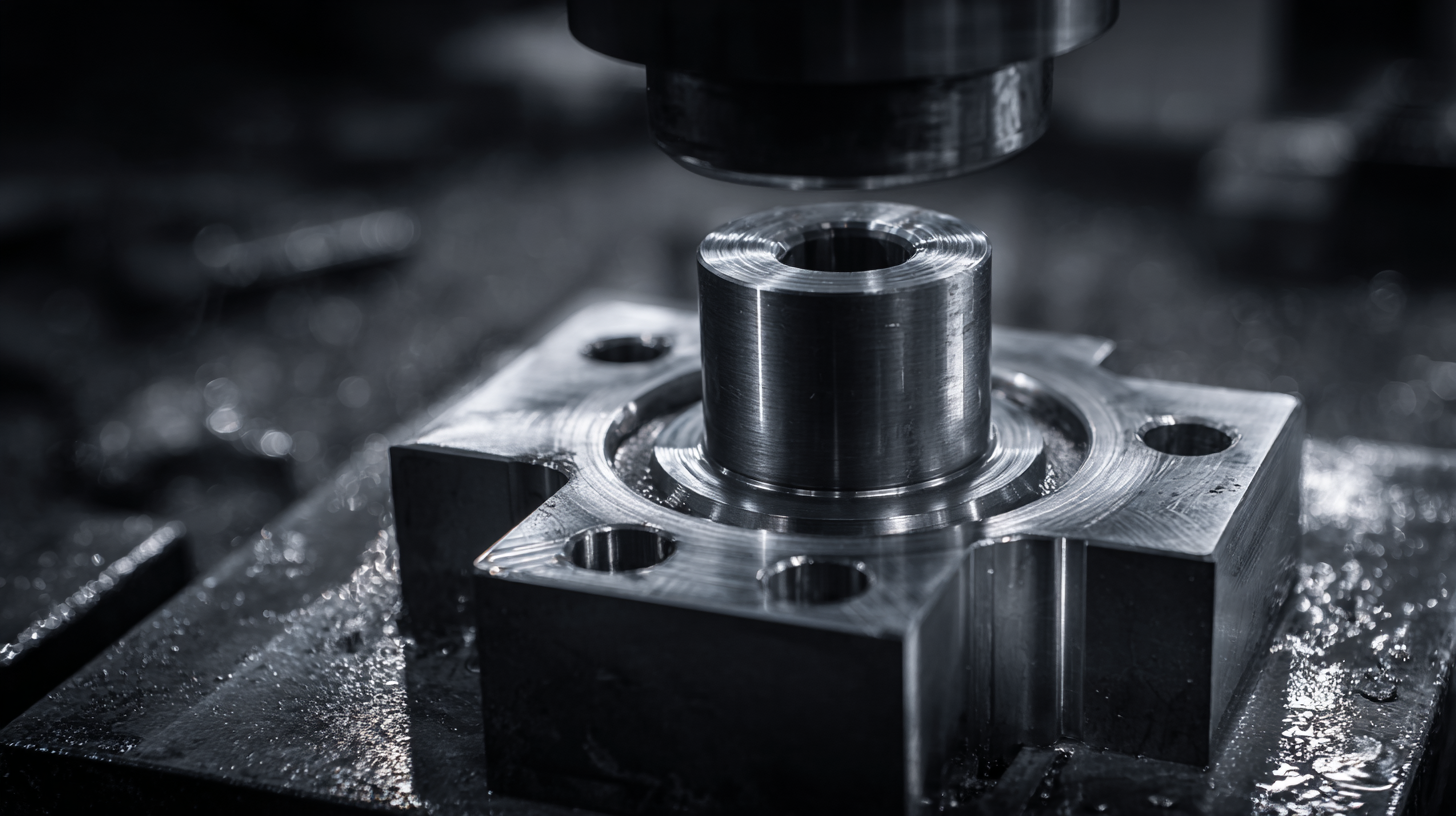

Machined steel parts play an indispensable role in precision engineering applications, underlining their significance in modern manufacturing processes. These components are essential for achieving the high tolerances and intricate designs required in various industries, including aerospace, automotive, and medical devices. The ability to accurately machine steel into complex geometries ensures that they can withstand severe operational conditions, thus enhancing the reliability and efficiency of the final products.

The growth of the CNC machine market, projected to reach nearly $200 billion by 2032, underscores the increasing demand for precision machined components. As industries move toward automation and require higher productivity with less waste, the use of advanced machining technologies will be critical. This trend is further supported by the burgeoning precision components and tooling systems market, where stainless steel and titanium components are in high demand for their strength and durability. As manufacturers continue to invest in precision engineering, the importance of high-quality machined steel parts will only continue to grow, solidifying their status as a critical element in modern manufacturing.

The demand for custom machined steel components is soaring as industries strive for enhanced precision and efficiency in manufacturing processes. This trend is largely driven by the rapid advancements in technology, which have made it possible to create highly specialized parts that meet the unique requirements of various applications. Manufacturers are increasingly turning to custom solutions to optimize performance, reduce waste, and improve the overall quality of their products. As a result, the market for machined steel parts is expanding, with companies investing in advanced machinery and techniques to fulfill this growing demand.

Moreover, the Global Plate Rolling Machine market is witnessing significant growth, reflecting the shifting landscape of modern manufacturing. As businesses prioritize customization and adaptability, the need for versatile plate rolling machines capable of producing tailored components is on the rise. Industry reports indicate that sectors such as automotive and aerospace are particularly keen on harnessing these advanced capabilities, driving the demand for precision components. With the global focus on sustainability and efficient production practices, the trend towards custom machined steel parts is likely to persist, reshaping the future of manufacturing processes across various industries.

In the realm of modern manufacturing, quality control in machining is paramount for ensuring not only optimal performance but also adherence to safety standards. The intricate process of machining steel parts necessitates rigorous inspection protocols to detect any deviations or defects that could compromise functionality or safety. Skilled operators must employ advanced technologies and methodologies to monitor machining processes, from the initial setup to the final inspection of machined parts. This proactive approach not only minimizes waste and rework but also enhances the overall reliability of the manufactured components.

Furthermore, the rising demand for high-quality machined steel parts is driving improvements in quality control measures. Manufacturers are increasingly adopting automated inspection systems and sophisticated data analysis techniques to evaluate the precision and integrity of machined products. By ensuring that each part meets stringent quality criteria, companies can guarantee that their products perform reliably in critical applications across various industries. As manufacturing continues to evolve, the role of effective quality control in machining will remain vital in upholding industry standards and customer satisfaction.