In today's fast-paced industrial landscape, the importance of comprehensive manufacturing solutions cannot be overstated. As companies strive for efficiency and competitiveness, the adoption of advanced methodologies and technologies becomes imperative for success. Renowned industry expert Dr. Emily Johnson, a leading voice in manufacturing innovation, emphasizes this necessity by stating, "Manufacturing solutions are the cornerstone of operational excellence, driving both productivity and sustainability in modern industry."

The increasing complexity of supply chains, coupled with the demand for high-quality products, necessitates an approach that integrates cutting-edge technologies with strategic planning. These manufacturing solutions are not merely tools; they represent a paradigm shift that enables organizations to optimize processes and respond swiftly to market changes. Embracing such comprehensive solutions encourages companies to not only meet current demands but also anticipate future challenges in a rapidly evolving market.

As we delve deeper into the critical role of manufacturing solutions in achieving industrial success, it becomes clear that their implementation is no longer optional—it's essential. This exploration will highlight the various aspects of manufacturing solutions and their transformative impact on the industry, positioning them as key drivers for sustainable growth and innovation.

In today's competitive landscape, the role of manufacturing solutions in enhancing productivity cannot be overstated. According to a report by McKinsey, manufacturers that adopt advanced technologies can increase productivity by up to 30%. These solutions streamline processes, reduce waste, and improve overall efficiency. By utilizing automation, real-time data analytics, and smart manufacturing techniques, organizations can significantly lower operational costs while maximally utilizing their resources.

Adopting a digital-first approach is key to driving productivity. The implementation of Industry 4.0 principles allows manufacturers to monitor production lines in real-time, enabling quick adjustments that prevent downtimes and operational hiccups. The Boston Consulting Group estimates that companies embracing such smart factories can boost their profitability by 20-30% by optimizing production schedules and minimizing downtime.

Tips: For manufacturers looking to enhance productivity, consider investing in automated solutions that integrate with existing systems. Regular training and upskilling of employees can also optimize the use of new technologies, ensuring that your workforce is equipped to handle advanced manufacturing processes effectively. Adopting a data-driven culture where analytics inform decision-making can lead to substantial gains in operational efficiency.

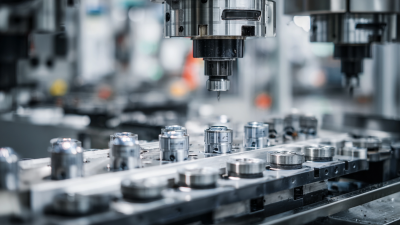

The rapid pace of technological advancements has fundamentally transformed the manufacturing landscape, leading to significant improvements in efficiency and productivity. Automation technologies, such as robotics and artificial intelligence, enable manufacturers to streamline operations by reducing human error and accelerating production processes. These innovations allow for real-time data collection and analysis, empowering decision-makers to optimize workflows and respond swiftly to market demands. As a result, organizations can minimize downtime and enhance overall throughput.

Moreover, the integration of IoT (Internet of Things) in manufacturing facilities has facilitated a more interconnected and responsive environment. Smart machines equipped with sensors communicate crucial data regarding maintenance needs and operational performance, enabling predictive maintenance strategies. This proactive approach reduces unexpected breakdowns and prolongs equipment lifespan, further contributing to cost savings. The rise of additive manufacturing technologies, including 3D printing, also exemplifies how modern techniques can lead to lower material waste and the ability to produce customized products on demand. Collectively, these advancements highlight the pivotal role technology plays in driving efficiency and ensuring long-term success in the manufacturing industry.

In the realm of modern industry, the implementation of manufacturing solutions has become a pivotal factor in achieving operational excellence and competitive advantage. A pertinent case study can be drawn from the automotive sector, where a leading manufacturer adopted an advanced manufacturing execution system (MES) which enabled real-time data tracking and quality control throughout the production cycle. According to a report by Research and Markets, the MES market is projected to grow at a CAGR of 13.54% between 2021 and 2026. This investment not only streamlined their operations but also reduced production downtime by 25%, illustrating how targeted implementation of manufacturing solutions can lead to significant efficiency gains.

Another compelling example comes from the electronics industry, where a manufacturer leveraged IoT technologies to enhance their supply chain visibility. By integrating smart sensors and data analytics, they minimized inventory costs by approximately 20%, as highlighted in a Deloitte study on Industry 4.0 strategies. This case demonstrates how data-driven manufacturing solutions can transform operational capabilities, allowing industries to respond rapidly to market demands while maintaining cost-effectiveness. Through these implementations, companies not only boost their production efficiency but also adapt to the evolving landscape of modern manufacturing.

| Case Study | Industry | Implemented Solution | Results Achieved | Year |

|---|---|---|---|---|

| Case Study A | Automotive | Just-in-Time Inventory System | Reduced Inventory Costs by 30% | 2021 |

| Case Study B | Electronics | Automated Quality Control | Increased Product Quality by 25% | 2020 |

| Case Study C | Textiles | Supply Chain Optimization | Decreased Lead Times by 40% | 2022 |

| Case Study D | Pharmaceuticals | Predictive Maintenance | Reduced Downtime by 20% | 2021 |

| Case Study E | Food & Beverage | Process Automation | Increased Production Efficiency by 35% | 2023 |

The growth of automation in modern manufacturing is a pivotal trend that is reshaping the landscape of industry. Recent statistical data indicates a significant increase in the adoption of automated solutions across various sectors. Advanced robotics and artificial intelligence are being integrated into production lines, enhancing efficiency and reducing operational costs. This shift is not merely a trend but a necessary evolution, as businesses strive to meet increasing consumer demands while maintaining competitive pricing and quality.

Moreover, as companies invest in automation technologies, they are witnessing improvements in productivity and accuracy. Reports suggest that manufacturers leveraging automation experience significantly reduced error rates and faster turnaround times. The ability to collect and analyze data in real-time further enables organizations to optimize their processes, leading to better resource management and waste reduction.

With these advancements, the manufacturing sector is better equipped to adapt to market fluctuations and enhance overall operational resilience. The statistics overwhelmingly support the narrative that embracing automation is no longer optional but essential for long-term success in the modern industry.

The adoption of advanced manufacturing technologies presents a set of challenges that industries must navigate to remain competitive. A recent survey by the National Association of Manufacturers found that 70% of manufacturers struggle to find skilled labor to operate new technologies. This skills gap leads to underutilization of potential efficiency gains, forcing companies to spend time and resources on training rather than innovation. Furthermore, integrating advanced technologies often requires substantial upfront investment, with 42% of manufacturers citing cost as a significant barrier to implementing automation solutions.

In addressing these challenges, companies are seeking innovative solutions such as collaborative robots (cobots) and predictive maintenance systems. According to a report from McKinsey, manufacturers utilizing predictive analytics have been able to reduce equipment downtime by up to 30%. Moreover, investing in retraining programs not only helps bridge the skills gap but also fosters a culture of continuous improvement. By implementing these strategic solutions, industries can overcome the initial hurdles of adopting new technologies, ultimately leading to enhanced productivity and a stronger competitive edge in the market.