In today's fast-paced world, mfg manufacturing stands at the forefront of industrial growth. The production of goods relies heavily on advanced techniques and technology. These methods not only enhance efficiency but also ensure quality. Companies that embrace mfg manufacturing often experience a noticeable boost in productivity. Yet, challenges remain.

For instance, integration of new technologies can be daunting. Many companies face difficulties balancing innovation with cost. Moreover, the need for skilled labor is ever-increasing. Workers must adapt to new tools and processes. This is not a simple task. Adaptation often requires time and patience.

Despite these hurdles, mfg manufacturing remains essential. It drives economies and shapes modern industries. The ripple effects can be seen across various sectors, from automotive to electronics. As industries evolve, so too must our approach to manufacturing. Understanding the significance of mfg manufacturing is crucial for a sustainable future.

MFG manufacturing is a cornerstone of industrial innovation today. According to a report by the International Data Corporation, manufacturing accounts for 16% of the global GDP. This sector is vital for modern economies, driving advancements across various fields. It fosters new technologies and enhances productivity.

Recent data shows that sectors such as aerospace and automotive depend heavily on modern manufacturing techniques. Over 70% of companies in these industries cite MFG innovations as key to their competitiveness. Automation, for instance, allows for faster production cycles. However, many organizations struggle to keep up with rapid technological changes. This gap between innovation and implementation poses significant challenges.

Innovative practices like additive manufacturing are transforming traditional production methods. A survey by Deloitte emphasizes that nearly 50% of manufacturers are investing in emerging technologies. Yet, the integration of these technologies isn't without hurdles. Workforce skills need to catch up with technological advancements. Critics argue that many companies face difficulties in upskilling their workforce effectively. Balancing innovation and labor skill development is crucial for sustained success in MFG manufacturing.

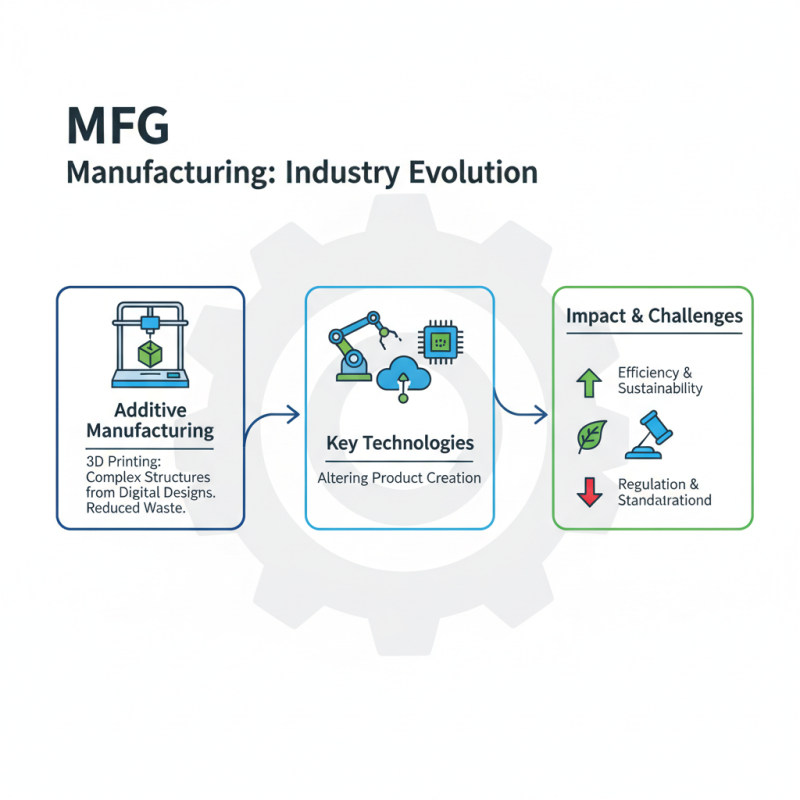

MFG manufacturing is essential for modern industries. Key technologies are altering how products are created. Additive manufacturing, also known as 3D printing, is a game changer. It allows the creation of complex structures from digital designs. This process reduces material waste, which is a significant benefit. However, it also poses challenges in terms of regulation and standardization.

Automation is another crucial technology. Robots streamline assembly lines, improving efficiency. They can work tirelessly, but they lack the adaptability of human workers. This creates a gap that needs addressing. While automation enhances productivity, it often raises concerns about job displacement for lower-skilled workers.

Advanced analytics play a vital role as well. Big data informs decision-making, allowing better resource allocation. However, not all companies can interpret this data effectively. Many struggle to adopt these technologies, leading to missed opportunities. The digital divide is real, and companies must find ways to keep up with the rapid changes in MFG manufacturing processes.

MFG manufacturing plays a vital role in shaping global economies. In 2021, the manufacturing sector contributed about 16% to global GDP, a staggering $16 trillion. This economic footprint underscores its significance. However, challenges exist. Supply chain disruptions, often due to geopolitical tensions, can hinder production and inflate costs.

Moreover, factories utilize cutting-edge technology. Data from industry studies show that automation can increase productivity by over 20%. Yet, reliance on machines raises concerns about job displacement. The workforce must adapt to new skills, or risk being left behind. The transition to smart manufacturing is essential, yet it requires careful planning.

The impact on global markets is profound. Emerging economies are ramping up production capabilities to compete. Strong demand for manufactured goods drives growth. In 2022, the global manufacturing output was projected to exceed $18 trillion. However, sustainable practices must be prioritized to minimize environmental harm. Balancing economic growth with ecological responsibility remains a challenge for many manufacturers.

Sustainability in MFG manufacturing poses numerous challenges. Many industries face increasing pressure to reduce their environmental impact. Waste disposal, energy consumption, and emissions remain critical issues. Factories often struggle to find efficient methods for waste management. Traditional processes can generate harmful byproducts, which raise concerns among communities.

There are solutions, but they require commitment. Implementing renewable energy sources is one step forward. Solar panels or wind energy can significantly lower carbon footprints. Companies should also consider recycling their materials. This not only reduces waste but also cuts costs. However, many companies remain hesitant. They fear the upfront investment may not yield immediate results.

Innovation plays a vital role in overcoming these hurdles. Adopting new technologies can streamline production. Automation could reduce labor costs and enhance efficiency. Still, this shift may lead to job losses, raising ethical questions. Balancing growth and sustainability demands careful consideration from all stakeholders.

This bar chart illustrates the various challenges and solutions in MFG manufacturing across different dimensions. It highlights the importance of sustainability practices in modern manufacturing, showcasing data on energy consumption, waste management, and innovation efforts from 2022.

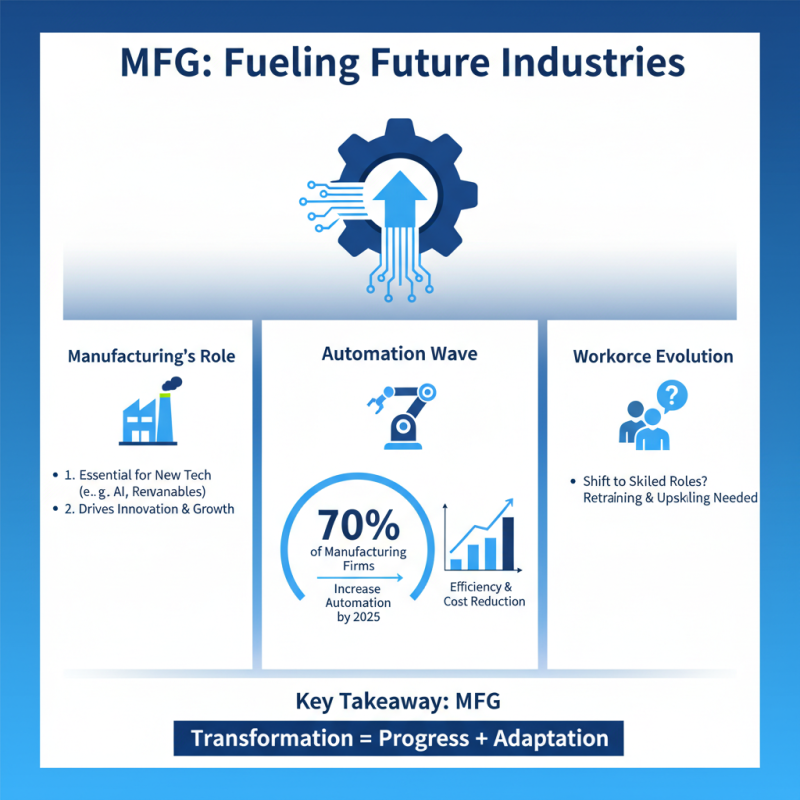

MFG manufacturing is vital for emerging industries. New technologies are driving transformation. A recent report showed that 70% of manufacturing firms plan to increase automation by 2025. This shift enhances efficiency and reduces costs, but it also raises questions about workforce displacement.

Emerging trends include additive manufacturing, known as 3D printing. This method can decrease material waste by up to 90%, according to industry studies. However, it's not without challenges. Production scalability and material limitations still create gaps that need solving. Companies must adapt to these problems while ensuring quality.

Another trend is the integration of IoT in manufacturing processes. Sensors and data analytics boost productivity. Despite these advancements, many companies struggle with data management. Only 30% effectively utilize data insights in their decision-making. Ensuring a seamless digital transformation remains a significant hurdle for countless manufacturers.