As we stand on the brink of a technological revolution, the landscape of modern manufacturing is undergoing a profound transformation. Industry experts, like John Schmidt, a leading authority in advanced manufacturing technologies, emphasize the significant impact these changes will have on production efficiency and innovation. Schmidt once stated, "In the realm of modern manufacturing, the integration of smart technologies not only streamlines processes but also opens the door to unprecedented levels of customization and responsiveness."

Today, the convergence of digitization, automation, and sustainable practices defines the core of modern manufacturing trends. Companies are increasingly adopting smart factories equipped with IoT devices, AI-driven analytics, and robotics to enhance operational performance. This shift not only boosts productivity but also enables manufacturers to respond swiftly to market demands while minimizing waste.

As we delve into the major trends that are shaping the future of the industry, it’s crucial to understand how these advancements are not just reformative but also transformative. The journey through the world of modern manufacturing reveals a path that leads to a more efficient, sustainable, and intelligent production environment.

The emergence of smart manufacturing technologies is revolutionizing the landscape of modern industry. With the integration of the Internet of Things (IoT), artificial intelligence (AI), and advanced robotics, manufacturers can now achieve enhanced efficiency, flexibility, and productivity. These technologies enable real-time data collection and analysis, allowing businesses to make informed decisions that optimize production processes and reduce downtime.

Furthermore, smart manufacturing promotes greater customization and personalization of products, catering to the evolving demands of consumers. By leveraging data analytics, companies can identify trends and preferences, leading to more targeted solutions that resonate with customers. The shift towards automated systems and intelligent machinery not only streamlines operations but also improves safety and reduces labor costs, making it a pivotal trend in the future of industry.

This chart illustrates the percentage of manufacturers adopting various smart manufacturing technologies in recent years.

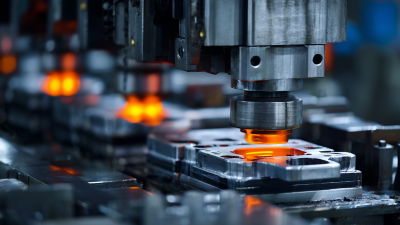

The impact of automation and robotics on production efficiency is profound and transformative, driving modern manufacturing toward unprecedented levels of productivity. By integrating robots into workflows, companies can significantly enhance speed and accuracy in production processes. These advanced machines are capable of handling repetitive tasks that previously required human effort, allowing human workers to focus on more complex and strategic responsibilities. As a result, manufacturers can achieve leaner operations with reduced error rates, leading to higher quality products and quicker turnaround times.

Moreover, the rise of automation is not only about increasing output but also about maximizing resource utilization. Smart robotics equipped with AI and machine learning capabilities can analyze data in real-time, adapting to changes in demand and optimizing workflows dynamically. This flexibility enables manufacturers to reduce waste and energy consumption, contributing to sustainable practices in the industry. Consequently, businesses that embrace these innovations find themselves better positioned to compete in a fast-evolving market, ensuring resilience and adaptability in their operations.

Sustainability practices are becoming a cornerstone of modern manufacturing processes, significantly impacting how industries operate today. Companies are increasingly adopting eco-friendly materials and energy-efficient technologies to minimize their environmental footprint. This shift not only meets regulatory requirements but also caters to the growing consumer demand for environmentally responsible products. As manufacturers integrate sustainable practices, they are discovering that these efforts often lead to cost savings and enhanced operational efficiency.

Tips for integrating sustainability into manufacturing include evaluating supply chains for sustainable sourcing, investing in renewable energy sources, and implementing waste reduction programs. Another effective strategy is to embrace circular economy principles, ensuring that products are designed for reuse and recycling. By actively engaging employees in sustainability initiatives, companies can foster a culture that prioritizes environmental stewardship.

Moreover, embracing digital technologies, such as IoT and AI, can facilitate sustainable manufacturing by optimizing resource use and reducing waste. These technologies provide valuable insights into production processes, enabling manufacturers to make informed decisions that align with sustainability goals. Prioritizing sustainability not only enhances brand reputation but also drives innovation, ensuring that businesses remain competitive in an evolving market.

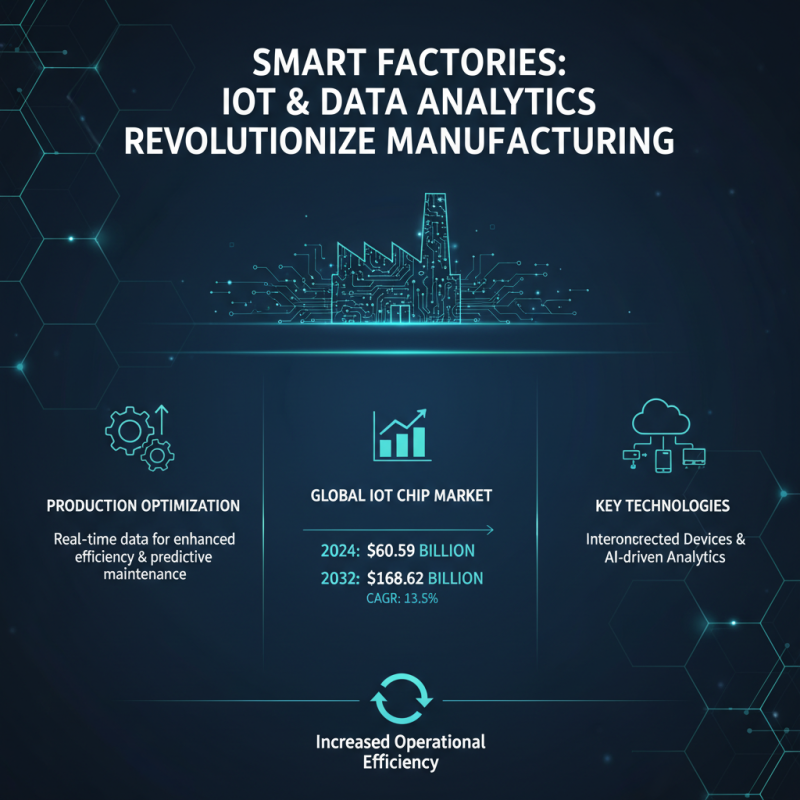

The integration of IoT and data analytics is revolutionizing modern manufacturing, paving the way for smart factories that optimize production processes through advanced technologies. The global IoT chip market is projected to reach a staggering $60.59 billion by 2024, with an estimated growth to $168.62 billion by 2032, reflecting a compound annual growth rate (CAGR) of 13.5%. This rapid expansion underscores the rising importance of interconnected devices and real-time data analytics in enhancing operational efficiency within manufacturing facilities.

Furthermore, the surge in Industry 4.0 technologies is driving the adoption of advanced analytics in manufacturing. As organizations embrace IoT, artificial intelligence, and cloud computing, they are shifting towards data-driven cyber-physical production systems that facilitate safer and more efficient manufacturing environments. The increasing integration of industrial robots, sensors, and machine vision exemplifies this trend, allowing manufacturers to harness big data for smarter decision-making and enhanced production workflows. Reports indicate that this transformation not only elevates productivity but also promotes a new era of distributed intelligent manufacturing.

Collaborative robotics, often referred to as cobots, are revolutionizing the manufacturing landscape by enhancing workforce productivity and ensuring safety. Unlike traditional industrial robots that operate in isolation, cobots are designed to work alongside human workers, complementing their skills and increasing operational efficiency. This synergy allows for a more flexible production environment, where tasks can be shared seamlessly between machines and people.

The integration of cobots into manufacturing processes not only boosts productivity but also addresses safety concerns. By taking on repetitive, dangerous, or ergonomically challenging tasks, cobots minimize the risk of workplace injuries and fatigue among human operators. This dual enhancement of efficiency and safety fosters a more sustainable workforce, enabling companies to maximize their output while adhering to rigorous safety standards. As industries continue to adapt to rapidly changing demands, the collaborative nature of these robotic systems will play a crucial role in shaping the future of modern manufacturing.