In the rapidly evolving landscape of modern manufacturing, industries are witnessing transformative trends that reshape their operational frameworks and strategies. According to a recent report from the International Society of Automation (ISA), the global manufacturing sector is expected to grow at a CAGR of 10.5% from 2021 to 2028, driven by advancements in automation, sustainability, and digital transformation. These trends not only enhance productivity but also foster a more adaptive and resilient manufacturing ecosystem.

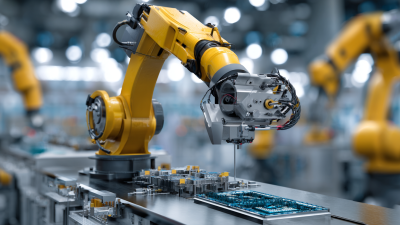

Modern manufacturing is increasingly characterized by the integration of smart technologies, including artificial intelligence (AI), the Internet of Things (IoT), and advanced robotics. A study by McKinsey & Company highlights that companies adopting these technologies can boost productivity by as much as 30%. Additionally, the emphasis on sustainability has led to innovative practices aimed at reducing waste and energy consumption, aligning with global initiatives to combat climate change. A report by the Manufacturing Institute forecasts a potential $600 billion in cost savings through sustainable manufacturing practices over the next decade.

As we delve into the top five modern manufacturing trends that are transforming industries in 2023, we will explore how these innovations are not only facilitating growth but also setting new standards for efficiency and environmental stewardship within the manufacturing sector.

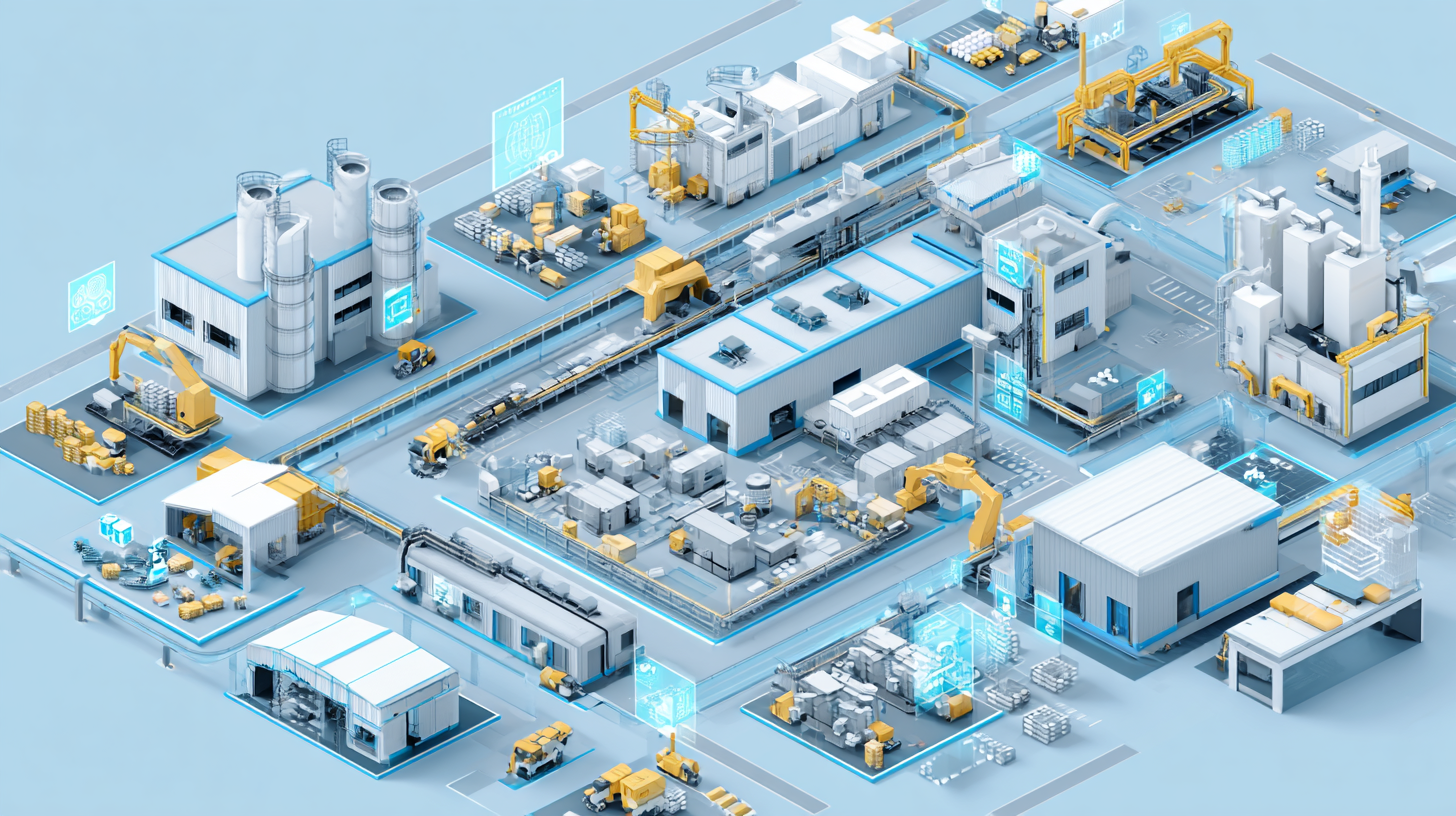

Smart manufacturing is transforming the industrial landscape, fundamentally reshaping production efficiency through the integration of the Internet of Things (IoT). By connecting machines and sensors, manufacturers can gather real-time data, enabling a more responsive and agile production process. This technology empowers manufacturers to streamline operations, reduce downtime, and enhance overall productivity. As factories evolve into smart environments, operational costs are significantly lowered, and decision-making becomes data-driven.

Smart manufacturing is transforming the industrial landscape, fundamentally reshaping production efficiency through the integration of the Internet of Things (IoT). By connecting machines and sensors, manufacturers can gather real-time data, enabling a more responsive and agile production process. This technology empowers manufacturers to streamline operations, reduce downtime, and enhance overall productivity. As factories evolve into smart environments, operational costs are significantly lowered, and decision-making becomes data-driven.

Tips: To leverage smart manufacturing effectively, consider investing in IoT-enabled equipment and prioritizing data analytics capabilities. Regular training sessions for staff on new technologies can further enhance operational efficiency and foster a culture of innovation.

The growth of smart manufacturing is reflected in the booming market for industrial management software, forecasted to reach $5.2367 billion in 2024 and $10.2476 billion by 2032. This illustrates a clear trend in the industry's commitment to adopting intelligent technologies. As we look towards 2030, sectors such as logistics and process manufacturing are also expected to adopt advanced automation, steering the trajectory of smart manufacturing towards unprecedented heights.

Tips: Focus on building an adaptable technology infrastructure that can scale according to industry demands while monitoring market trends to stay ahead of competition. Engaging with industry peers through forums and workshops can also lead to valuable insights and collaborative opportunities.

Sustainable practices in manufacturing are increasingly becoming essential as industries strive to meet both consumer demand and environmental goals. According to a recent report by McKinsey & Company, sustainable practices can lead to a 15-20% reduction in supply chain costs. This transformation is driven by the rising awareness of climate change and resource scarcity, pushing manufacturers to adopt circular economy principles and reduce waste. In fact, the global market for green manufacturing is projected to reach $1.3 trillion by 2025, showcasing the urgency and opportunity for manufacturers to innovate sustainably.

Moreover, recent data from the International Energy Agency indicates that manufacturing accounts for 54% of global energy consumption, underscoring the impact of energy-efficient practices. Transitioning to renewable energy sources not only helps in reducing carbon footprints but can also enhance energy security and cost-effectiveness in operations. As companies invest in smarter, more efficient technologies, they are not just meeting regulatory requirements but are also appealing to a growing segment of eco-conscious consumers. With these advancements, sustainable manufacturing is no longer seen as a trend but rather as a strategic imperative for long-term success in the competitive landscape.

| Trend | Description | 2023 Growth Rate (%) | Environmental Impact | Sustainability Practices |

|---|---|---|---|---|

| Automation | Increased use of robotic and AI technologies in production lines. | 15% | Reduced labor emissions by 20% | Implementation of smart manufacturing practices. |

| Sustainable Materials | Shift towards biodegradable and recyclable materials in products. | 12% | Lowered carbon footprint by 25% | Adoption of circular economy principles. |

| Digital Twin Technology | Creation of digital replicas of physical assets for real-time monitoring. | 20% | Enhanced resource efficiency by 30% | Optimization of manufacturing processes with data analytics. |

| Supply Chain Transparency | Increased visibility and accountability in the supply chain. | 10% | Reduced waste by 15% | Use of blockchain for traceability. |

| Energy Efficiency | Improving energy consumption patterns in manufacturing processes. | 18% | Achieved 35% reduction in energy usage | Investment in renewable energy sources. |

Artificial Intelligence (AI) is playing a pivotal role in modern manufacturing, revolutionizing production processes and driving industry growth. According to a recent report by McKinsey, 70% of companies are integrating AI technologies into their operations to improve efficiency and reduce operational costs. This shift towards AI-powered solutions is not just about automation; it also involves data-driven decision-making that enhances the ability of manufacturers to forecast demand and respond dynamically to market changes. By leveraging AI algorithms, businesses can optimize logistics, inventory management, and production schedules, leading to a significant reduction in waste and an increase in overall productivity.

The impact of AI on manufacturing is further underscored by data from Gartner, which predicts that by 2025, AI will contribute to a $3 trillion increase in total economic output in the manufacturing sector alone. This impressive growth is attributed to AI's capacity to identify patterns and insights from vast amounts of production data, enabling manufacturers to refine processes and innovate product design. As companies adopt smart factories equipped with AI, they are witnessing improved quality control and accelerated time-to-market for new products, marking a transformative shift in industry capabilities and competitiveness.

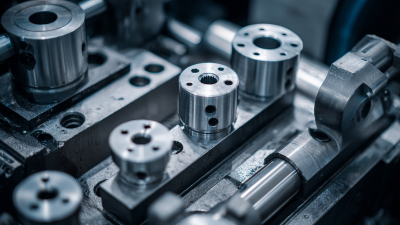

Additive manufacturing is transforming design and prototyping techniques across various industries, significantly improving efficiency and product development timelines. This innovative approach allows for the rapid creation of complex geometries that were previously challenging to manufacture using traditional methods. In sectors like wearable technology, the demand for body-conformable electronics is driving advancements in fabrication techniques. These capabilities are essential for developing devices that seamlessly integrate with the human body, enhancing user experience and functionality.

Moreover, the integration of additive manufacturing in drug delivery systems, particularly with 3D-printed microneedles, demonstrates its potential in precision medical applications. These tailored solutions lead to significant advancements in neurological therapies, offering new therapeutic avenues. Additionally, companies are embracing new developments like tool-less origami machines for rapid prototyping, which streamline the production process and reduce time-to-market. As industries adopt these modern manufacturing trends, the future of design and prototyping appears increasingly dynamic and responsive to specific market needs.

In 2023, the manufacturing landscape is increasingly shaped by data-driven decision making, where organizations leverage analytics to fuel strategic growth. This trend is revolutionizing how industries approach operations, enabling real-time insights that empower leaders to make informed choices. Manufacturers are utilizing advanced analytics tools to sift through vast amounts of data generated from production processes, supply chains, and customer interactions, identifying patterns and trends that drive efficiency and innovation.

By adopting a data-centric mindset, manufacturers can optimize their workflows, reduce costs, and enhance product quality. Predictive analytics, for instance, allows companies to foresee potential equipment failures, enabling proactive maintenance that minimizes downtime. Additionally, organizations are turning to business intelligence platforms that offer dashboards and visualizations, making complex data accessible and actionable across departments. This collaborative approach fosters a culture of transparency and agility, equipping teams to swiftly respond to market demands and rapidly evolving industry standards, ultimately leading to sustained growth in a competitive market.