The landscape of manufacturing is undergoing a significant transformation, primarily driven by advancements in technology such as CNC machine fabrication. According to a report by Grand View Research, the global CNC machines market size is expected to reach $100.68 billion by 2026, expanding at a CAGR of 6.5% from 2019 to 2026. This growth underscores the increasing adoption of CNC technologies across various sectors, enhancing precision and efficiency in production processes.

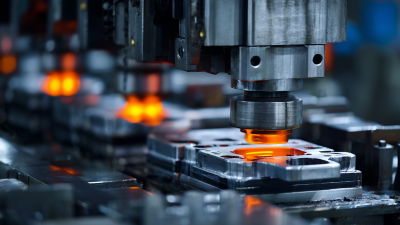

With the rise of Industry 4.0, manufacturers are leveraging smart technologies and automation to revolutionize their operations. CNC machine fabrication not only reduces human error but also streamlines production cycles, ultimately leading to cost savings and improved product quality. As businesses seek to remain competitive in a rapidly evolving marketplace, understanding the future implications of CNC technology becomes essential for stakeholders aiming to harness the full potential of advanced manufacturing.

The digital transformation in CNC machining is reshaping the landscape of manufacturing, bringing forth innovative trends and statistics that are defining the industry's future. Key advancements in automation, artificial intelligence, and the Internet of Things (IoT) are enabling manufacturers to enhance production processes, improve precision, and reduce waste. For instance, predictive maintenance technologies are being adopted to monitor machine health in real-time, minimizing downtime and optimizing operational efficiency. This shift not only lowers costs but also increases the speed of production, allowing companies to meet the demands of a fast-paced market.

In terms of statistics, a recent survey indicates that over 70% of manufacturers are investing in digital tools, underscoring a significant commitment to modernization. Furthermore, the integration of advanced software solutions for data analysis is helping businesses gain insightful information to drive decision-making and strategy. As these trends continue to evolve, the CNC machine fabrication sector stands poised for a revolutionary change that promises enhanced capabilities and smarter manufacturing practices, solidifying its critical role in various industries moving forward.

The integration of artificial intelligence (AI) and machine learning in CNC machine fabrication is setting new standards for efficiency and productivity in manufacturing. AI-driven programming automation is transforming traditional machining processes, enabling more complex operations to be executed with greater precision and less human intervention. Startups are emerging with innovative solutions, such as the recent $3 million investment in a company aiming to enhance CNC machining through AI, demonstrating investor confidence in the sector's potential to revolutionize production methods.

As manufacturers adopt smart manufacturing technologies, tools that incorporate AI are becoming essential for sustaining competitive advantages. For instance, the introduction of advanced software solutions is simplifying programming complexities and enabling real-time adaptations to production requirements. Companies like Foxconn are also embedding AI deeply into their operations, leveraging data analytics to optimize manufacturing workflows and improve overall efficiency. This technological evolution is not just reshaping how machines operate; it is redefining the future landscape of manufacturing as a whole.

The advent of Industry 4.0 is transforming the landscape of CNC machine fabrication by integrating advanced technologies such as the Internet of Things (IoT), artificial intelligence (AI), and big data analytics. This new era of digital manufacturing not only enhances the efficiency of CNC machines but also optimizes the entire production process. With real-time data collection and analysis, manufacturers can quickly adjust their operations, reducing downtime and minimizing waste while increasing overall productivity.

Tips for successful integration of Industry 4.0 into CNC machining include investing in employee training to ensure that your workforce is equipped to adapt to new technologies. Additionally, adopting a modular approach to machinery can enable easier updates and enhancements as technologies evolve. Lastly, companies should prioritize cybersecurity measures to protect sensitive data and maintain operational integrity in an increasingly connected environment.

As manufacturers embrace automation, they are witnessing improved precision and speed in their processes. Smart machines can communicate with each other, allowing for seamless adjustments and better workflow management. This not only saves time but also empowers organizations to respond to market demands more swiftly and effectively.

Sustainability has emerged as a critical focus for CNC machine fabrication, as manufacturers seek to minimize waste and energy consumption while meeting the demands of a rapidly changing market. Advances in digital transformation play a pivotal role in this evolution, utilizing technologies like the Industrial Internet of Things (IIoT), automation, and Manufacturing Execution Systems (MES) to enhance operational efficiency. These technologies allow for smarter resource management, enabling companies to cut costs and reduce their environmental impact.

Additionally, innovations in design software are simplifying the process for manufacturers to assess the environmental implications of their production choices. Tools designed to evaluate the carbon footprint of various design options empower decision-makers to opt for more sustainable practices at every stage of the manufacturing process. From automotive to aerospace, manufacturers are increasingly adopting these sustainable engineering practices, highlighting a broader trend towards eco-friendly production methods that align economic efficiency with environmental responsibility.

| Dimension | Description | Measurement | Impact on Sustainability |

|---|---|---|---|

| Material Efficiency | Amount of raw materials used in production | 70% efficiency | Reduced waste by 30% |

| Energy Consumption | Total energy used per machine cycle | 2 kWh/cycle | Lower energy costs and CO2 footprint |

| Recyclability | Percentage of materials that can be recycled | 90% | Supports circular economy |

| Waste Reduction | Amount of scrap generated per production | 5% of total output | Minimizes environmental impact |

| Machining Time | Duration of CNC operations | 45 minutes per part | Efficient use of machine time |

The global CNC machine market is witnessing remarkable growth, with projections indicating an increase from $101.22 billion in 2025 to $195.59 billion by 2032, reflecting a Compound Annual Growth Rate (CAGR) of 9.9%. This surge is driven by technological innovations, particularly in artificial intelligence and robotics, which are revolutionizing machining processes. These advancements enable manufacturers to enhance precision, reduce lead times, and optimize production efficiency, making CNC machining an irresistible choice in various industries.

Additionally, niche segments within the CNC market are also expanding significantly. For instance, the CNC slitting lathes market is expected to grow from $1.7 billion in 2025 to $2.8 billion by 2035, fueled by a CAGR of 5.3%. Meanwhile, the CNC machine tools sector is poised for a notable increase of USD 21.9 billion between 2025 and 2029, largely propelled by the rising demand for high-precision and multi-axis machining centers. The emergence of AI technologies is redefining market dynamics, indicating a future where CNC machining becomes even more integral to manufacturing excellence.