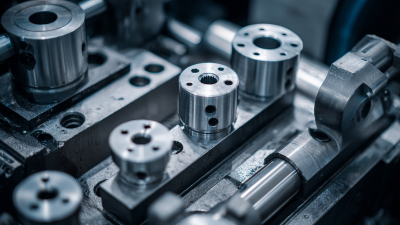

Selecting the right machined steel parts for your project can significantly impact the overall success and functionality of your applications. According to a recent report from the Precision Machined Products Association (PMPA), the market for machined steel parts is expected to grow at a compound annual growth rate (CAGR) of 4.2% over the next five years, driven by advancements in manufacturing technology and an increasing demand for high-precision components across various industries. This underscores the importance of careful selection to ensure quality and performance.

Industry expert, Dr. Emily Roberts, a leading authority in machining processes, emphasizes the importance of selection criteria: “Choosing the right machined steel parts is crucial; it can make or break the integrity of the final product.” Her insights highlight the necessity for engineers and project managers to consider factors such as material properties, tolerances, and surface finishes when sourcing machined steel parts. Understanding these components not only optimizes production efficiency but also enhances the durability and reliability of the finished product. As the industry evolves, making informed decisions in selecting machined steel parts will remain a foundational pillar for successful project execution.

When selecting machined steel parts for your project, several critical factors must be considered to ensure optimal performance and durability. The first factor is material properties, which include tensile strength, hardness, and corrosion resistance. According to the American Iron and Steel Institute (AISI), specific steel grades are better suited for different applications; for instance, AISI 4140 steel is known for its high strength and toughness, making it ideal for high-stress environments. Evaluating these properties against your project requirements will facilitate selecting the right steel grade, ensuring that the machined parts can withstand the operational demands.

Another important consideration is the manufacturing and machining processes involved in producing the steel parts. Precision machining techniques, such as CNC machining, can achieve tolerances as tight as ±0.001 inches, which is crucial for applications requiring high accuracy. Reports from the National Institute of Standards and Technology (NIST) highlight that adherence to stringent quality control standards during manufacturing can significantly reduce failure rates in machined components. Ensuring that the chosen supplier employs advanced technology and adheres to industry standards will enhance the reliability of the components and ultimately the success of your project.

When selecting machined steel parts for your project, understanding the different types of steel and their mechanical properties is crucial. Steel can be broadly categorized into several types, including carbon steel, alloy steel, stainless steel, and tool steel. Each type exhibits distinct characteristics that influence their suitability for various applications. For example, carbon steel is known for its high strength and hardness but may lack corrosion resistance. In contrast, stainless steel offers excellent resistance to rust and corrosion, making it ideal for environments exposed to moisture and chemicals.

Mechanical properties such as tensile strength, yield strength, and hardness are vital metrics when choosing the right steel type. According to a report by the American Society for Testing and Materials (ASTM), the tensile strength of carbon steel can range from 370 to 700 MPa, while stainless steel typically ranges from 520 to 1100 MPa. These factors not only determine how the material will perform under stress but also indicate how it can be machined. Choosing the right material based on mechanical properties ensures better performance and longevity in your applications.

Tip: Before making a selection, assess the specific demands of your project, including load-bearing requirements and exposure conditions. This analysis will guide you toward the most suitable steel type. Additionally, consider consulting with material specialists who can provide insights tailored to your project needs. This proactive approach will aid in avoiding costly mistakes and ensuring optimal material performance.

When selecting machined steel parts for your project, understanding tolerances and specifications is crucial for ensuring the parts meet your requirements. Tolerance refers to the allowable deviation from a specified dimension, and it plays a significant role in how the parts will fit and function within an assembly. According to a report from the American Society of Mechanical Engineers (ASME), tighter tolerances can increase production costs due to the need for more precise machining processes. However, balancing cost and precision is essential; for example, a tolerance of ±0.005 inches might suffice for low-stress applications, while tighter tolerances of ±0.001 inches could be necessary for high-performance components.

When evaluating specifications, it is important to consider the material's properties, including hardness, tensile strength, and corrosion resistance. The American National Standards Institute (ANSI) provides guidelines that can help manufacturers select appropriate grades of steel based on application needs. For instance, parts meant for high-stress environments should ideally be made from carbon steels with specific alloying elements to enhance their mechanical properties.

Tips: Always communicate clearly with your machining supplier regarding your specifications and expectations. Request detailed technical drawings that highlight critical dimensions and tolerances. Additionally, consider utilizing simulation software to predict how variances in machining might affect the final assembly, which can help avert costly errors in production.

When selecting machined steel parts for a project, achieving a balance between quality and budget is critical. According to a report by the Machinery Market, the average cost of steel parts can significantly vary based on the manufacturing process, with conventional machining averaging around $50 to $100 per hour, while advanced techniques like CNC machining can range from $75 to over $200 per hour. Understanding these costs in the context of project requirements is essential for making informed decisions.

Quality should not be compromised for cost savings. Industry standards indicate that high-quality machined steel has a tensile strength of circa 350 MPa, which ensures durability and reliability in various applications. Investing in higher quality parts may lead to reduced maintenance costs and longer service life, which can ultimately save money in the long run. A study by the Steel Manufacturers Association reveals that while the upfront cost of high-grade steel components can be higher, the lifecycle cost can be lower due to these factors. Thus, evaluating both the initial expenditure and long-term benefits is paramount in balancing quality and budget effectively in steel parts selection.

When sourcing machined steel parts for your project, selecting the right supplier is crucial for ensuring quality and efficiency. Begin by identifying suppliers who specialize in steel machining and have a proven track record in your specific industry. Research their capabilities, including the range of materials they can work with and their production methods. It is also beneficial to assess their certifications and adherence to industry standards, which can provide insights into their commitment to quality control.

Furthermore, establishing clear communication with potential suppliers is essential. Discuss your project requirements in detail, including dimensions, tolerances, and delivery timelines. A well-defined specification not only aids in obtaining accurate quotes but also helps ensure that the supplier fully understands your expectations. Additionally, evaluating their responsiveness and willingness to collaborate can indicate their reliability and customer service, which are critical for maintaining a successful working relationship throughout your project. Engaging in a preliminary trial order may also be a practical step to gauge the supplier's capabilities before committing to larger volumes.