Steel stamping machines play a crucial role in modern manufacturing. These machines transform raw materials into precise metal components. According to industry expert John Marshall, "The steel stamping machine is the backbone of efficient production lines."

In various sectors, steel stamping machines are essential for creating automotive parts, appliances, and industrial equipment. The speed and accuracy they offer significantly reduce production time and costs. Each stamped piece maintains consistent quality, a necessity for high-volume manufacturing.

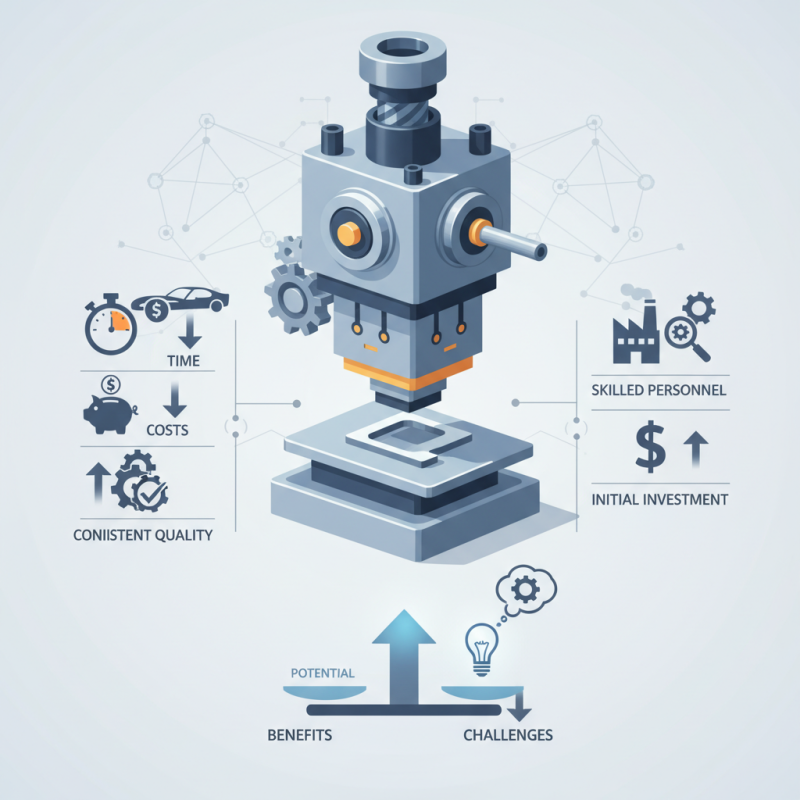

Yet, challenges exist in this technology. Maintenance and operation of these machines require skilled personnel. Additionally, initial costs can be high. Investing in a steel stamping machine must be weighed against potential returns. Overall, despite these imperfections, the benefits are apparent. A thoughtful approach is vital for maximizing their potential.

Steel stamping machines offer significant advantages in manufacturing. They enable high precision and repeatability in producing metal parts. This consistency helps maintain quality across large batches. Manufacturers can save time and costs through quicker production cycles. Reduced waste also contributes to better operational efficiency.

When implementing steel stamping machinery, consider the material types. Different materials may require distinct stamping techniques. Not all machines are suited for every task. Adjustments may be necessary. This can lead to trial and error situations.

**Tip:** Always analyze production needs before investing. Understand capacity limits. Evaluate how machines can integrate into current processes for smooth operations. Testing setups can uncover unforeseen challenges. It’s a chance to refine techniques and improve overall production. Each step taken will enhance long-term outcomes.

Steel stamping is vital in automotive and aerospace sectors. It provides precision, efficiency, and durability in manufacturing components. According to a recent industry report, steel stamping accounts for over 60% of metal forming processes in these fields. This highlights its importance in producing high-quality parts quickly.

In the automotive industry, steel stamping is used for body panels, chassis components, and other parts. These components must withstand various stresses. A well-stamped part ensures safety and performance. Recent data shows that companies using advanced steel stamping technology can reduce production costs by 15% and increase output by 20%. This efficiency is crucial in today’s competitive market.

Aerospace benefits similarly. Steel stamped parts are integral to structural components and systems. The need for lightweight yet strong materials is critical. In fact, aerospace companies have reported a 10% reduction in weight by switching to optimized stamped parts. However, the industry faces challenges, such as maintaining stringent quality control. Even minor flaws can lead to significant safety issues. Continuous improvement and innovation are required to overcome these obstacles.

Steel stamping significantly boosts production efficiency and cuts costs. This process involves shaping steel into precise forms. It is widely used in automotive and industrial applications. The automation in steel stamping reduces labor costs. Machine precision minimizes material waste, which also contributes to savings.

Companies using steel stamping often see faster turnaround times. This process enhances product consistency and quality. As production ramps up, the cost per unit decreases. Shorter lead times mean quicker market response. However, transitioning to this method requires an upfront investment.

Tip: Regular maintenance of stamping machines is crucial. It prevents unexpected breakdowns and keeps production smooth. Identify bottlenecks in your process. This will help in optimizing the workflow. It’s essential to regularly review your techniques and adapt as needed. Remember, innovation is a continuous journey.

| Benefit/Application | Description | Impact on Production | Impact on Cost |

|---|---|---|---|

| High Precision | Produces parts with tight tolerances and low variability. | Increased consistency in production runs. | Reduced waste and rework costs. |

| Reduced Lead Time | Faster production cycles thanks to automation. | Quicker response to market demands. | Lower labor costs and inventory carrying costs. |

| Versatility | Applicable for various materials including steel, aluminum, and more. | Ability to adapt to different production needs. | Cost-effective solution across multiple projects. |

| Improved Material Utilization | Optimizes the use of raw materials through precise cuts. | Less scrap generated during production. | Decreased material costs and improved ROI. |

| Complex Part Designs | Ability to create intricate shapes and designs. | Enhanced product functionalities and aesthetics. | Potential for better market positioning. |

Technological innovations are reshaping the landscape of steel stamping machinery. Automation and artificial intelligence drive efficiency and precision. Machines now operate with remarkable speed. Less human intervention means fewer mistakes. This technology reduces production costs significantly.

New materials enhance the durability of stamping machines. Manufacturers are exploring lightweight alloys and advanced composites. These developments improve overall performance and longevity. However, the transition to new technology can be challenging. Not all operators easily adapt to these changes.

Data analytics plays a vital role in modern stamping. Real-time monitoring helps identify issues before they escalate. Predictive maintenance becomes more feasible. Yet, not every factory is equipped with the latest tools. Some still rely on outdated equipment, leading to inefficiencies. The industry must find ways to balance innovation with existing practices.

The steel stamping equipment industry is witnessing significant changes. Companies are moving towards automation to increase efficiency. This shift leads to faster production cycles and consistent quality. However, this trend requires a skilled workforce to operate new technologies.

Market growth in this sector is driven by demand from various industries. Automotive, aerospace, and consumer products are major contributors. As these industries expand, the need for high-quality stamped products rises. Companies must adapt to meet customer needs without sacrificing quality. This is a constant challenge for many manufacturers.

Innovative technologies like artificial intelligence and IoT are emerging. These advancements enable better monitoring and improve process efficiency. However, integrating these technologies can be daunting. Companies must invest time and resources to harness their full potential. Balancing innovation with practicality is essential for sustained growth.