Choosing the right steel fabrication machinery is a critical step for businesses in the construction and manufacturing sectors. As projects become more complex and demand for precision increases, having the right equipment is not just an operational necessity but a competitive advantage. Steel fabrication machinery plays a pivotal role in shaping, cutting, and assembling steel components, making the selection process vital for efficiency and productivity.

When considering steel fabrication machinery, several factors come into play, including the type of materials, the volume of production, and the specific applications required. It’s essential to evaluate the capabilities of different machines and their suitability for your particular tasks. Understanding the nuances of each type of equipment can help streamline operations and maximize return on investment.

In this guide, we will explore essential tips for selecting the most appropriate steel fabrication machinery tailored to your distinct needs. Whether you're upgrading your existing machinery or starting a new project, a well-informed decision can significantly impact your overall efficiency and outcomes in the competitive landscape of steel fabrication.

When considering the right steel fabrication machinery, the first step is to

thoroughly understand your specific fabrication needs and requirements. According to a recent industry report by the

Fabricators and Manufacturers Association, around 75% of steel fabricators

cite improved efficiency as a key driver in their machinery investments. This emphasizes the importance of aligning

the capabilities of the machinery with your production goals. Factors such as the types and thicknesses of materials to

be processed, expected production volumes, and the complexity of the projects must all be carefully evaluated.

Additionally, energy consumption and the sustainability of the machinery are increasingly becoming consideration points in the fabrication sector. The American Institute of Steel Construction indicates that machinery with higher energy efficiency can reduce operational costs by up to 20%. Thus, understanding the lifecycle of the equipment, including maintenance requirements and energy consumption metrics, is essential to making an informed decision. The right machinery not only meets the current demands but also adapts to future challenges in steel fabrication, promoting long-term growth and sustainability for your operations.

When selecting steel fabrication machinery, it is crucial to focus on key features that align with your operational needs. First, consider the type of material and thickness you will be working with. Machinery designed for specific steel grades or thickness ranges will provide better performance and durability. Additionally, the cutting speed and precision are vital; advanced machinery typically offers higher speeds and more accurate cutting capabilities, ensuring better quality finishing and reduced waste.

Another important feature to evaluate is the machine's versatility. Look for equipment that can perform multiple functions, such as cutting, welding, and bending. This versatility can enhance productivity and reduce the need for additional machines, saving both space and costs. Moreover, automation features can significantly improve efficiency, allowing for quicker setups and minimizing manual labor. Integrating advanced technology, such as CNC controls, can enable precise operations and greater flexibility in production runs, which is essential for meeting diverse project requirements.

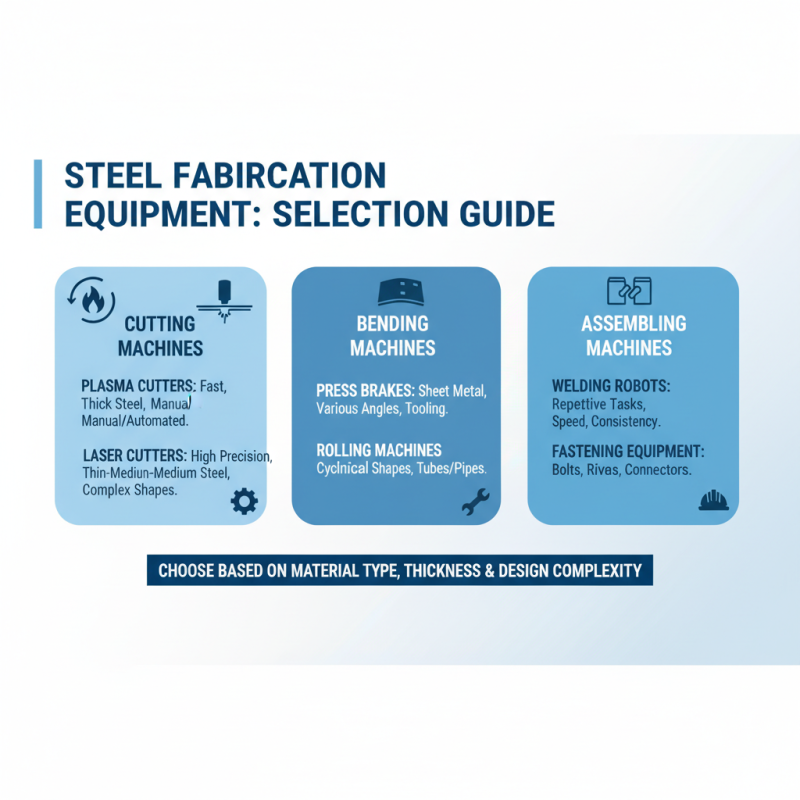

When selecting the right steel fabrication equipment, it's essential to compare the various types available to meet specific project requirements. The primary categories include cutting, bending, and assembling machines. Cutting machines such as plasma cutters and laser cutter offer precision and speed, making them ideal for intricate designs and tough materials. Understanding the thickness and type of steel you will be working with can help determine which cutting technology will yield the best results.

Bending machines, including press brakes and roll benders, are crucial for shaping steel into desired forms. Each type of bending equipment varies in capacity and flexibility, so it’s important to consider the thickness and size of the steel being processed. Similarly, assembling machines play a vital role in the final manufacturing stage, ensuring that welded parts fit together perfectly. Evaluating the specific needs of your project, such as volume, complexity, and desired finish, will help you make informed decisions when comparing these essential types of steel fabrication machinery.

When considering the purchase of steel fabrication machinery, assessing your budget and ensuring cost-effectiveness are crucial steps that can significantly impact your business’s financial health. Developing a comprehensive budget requires understanding both the initial acquisition cost and the long-term operational expenses associated with the machinery. This includes maintenance, energy consumption, and any necessary upgrades over time. By closely analyzing these factors, you can avoid the pitfalls of overspending or underestimating future costs, which can lead to business strain and decreased profitability.

Another important aspect is evaluating the return on investment (ROI). Look for machinery that offers a balance between performance and price. While cheaper options may seem attractive, they often come with hidden costs, such as higher maintenance or lower efficiency over time. Conversely, investing in quality machinery with advanced features can lead to greater productivity and reduced downtime, ultimately justifying the higher initial expense. Therefore, it is essential to perform a thorough analysis, including comparing different machinery’s capabilities and efficiencies, to ensure that your choice aligns with your operational needs and financial constraints, allowing for sustainable growth in your fabrication business.

When choosing steel fabrication machinery, the reputation of the manufacturer is crucial. A well-regarded manufacturer often indicates a commitment to quality and reliability. Look for companies with extensive experience in the industry, as they are more likely to understand the nuances of steel fabrication and what manufacturers need to succeed. Reading reviews and testimonials can provide insights into other customers' experiences, helping you gauge whether the manufacturer delivers on its promises. Additionally, consider seeking recommendations from industry peers who have firsthand knowledge of the machinery performance and manufacturer support.

After-sales support is another critical factor when evaluating potential machinery suppliers. Solid after-sales service can dramatically affect your operations, especially if issues arise post-purchase. It's advisable to inquire about the availability of technical support, warranty policies, and the duration of parts availability. A manufacturer that offers comprehensive training programs and responsive support can significantly enhance your team's efficiency and machine uptime.

**Tips:** Before making a decision, ensure to outline your specific needs and compare multiple manufacturers. Assess the level of customization available in their machines to tailor them to your production processes effectively. Lastly, don't overlook the importance of communicating directly with sales representatives to clarify before purchasing and ensure that you have a good rapport for any future needs.

| Criteria | Details | Importance Rating (1-5) |

|---|---|---|

| Manufacturer Reputation | Assess the history and reviews of manufacturers based on customer experiences and industry standing. | 5 |

| After-Sales Support | Evaluate the availability of technical support, parts replacement, and maintenance services post-purchase. | 4 |

| Machinery Versatility | Consider if the machinery can handle various types of steel and fabrication processes to meet diverse needs. | 4 |

| Training and Resources | Check if manufacturers provide training sessions and resources for staff to maximize machinery use. | 3 |

| Warranty and Service Agreements | Look for comprehensive warranty options and maintenance agreements that protect your investment. | 5 |

| Technology and Innovation | Investigate the incorporation of advanced technology like automation and precision in machinery design. | 4 |