In the ever-evolving landscape of manufacturing, state contract manufacturing has emerged as a vital segment, serving both public and private sectors with a range of specialized production services. Businesses and government entities alike are increasingly turning to contract manufacturers to leverage their expertise and resources, ensuring efficiency and quality in the production process. With tailored solutions that can adapt to varied needs, state contract manufacturers are pivotal in driving innovation and productivity.

This article presents a comprehensive overview of the top 10 state contract manufacturing companies you should know about. These companies not only excel in technical capabilities but also boast a keen understanding of compliance and regulatory requirements specific to their operational environments. By exploring their unique strengths and offerings, stakeholders can make informed decisions when seeking reliable manufacturing partners. Whether you are a start-up looking to scale or a seasoned enterprise aiming for operational excellence, understanding the landscape of state contract manufacturing is crucial in achieving strategic objectives.

The state contract manufacturing industry has experienced significant growth over the past few years, driven by increasing demand for customized products and the need for cost-efficient production solutions. According to a recent report by IBISWorld, the contract manufacturing sector in the United States is expected to reach approximately $345 billion by 2025, with an annual growth rate of about 3.5% from 2020. This upward trend underscores the crucial role contract manufacturers play in various sectors, including aerospace, automotive, medical devices, and consumer electronics.

As companies seek to enhance supply chain efficiency, many are turning to state contract manufacturers to leverage their specialized expertise and advanced technologies. These firms offer a plethora of services, ranging from design and prototyping to production and logistics, allowing businesses to focus on their core competencies. A noteworthy statistic from a Deloitte report reveals that 70% of manufacturing executives believe that outsourcing to contract manufacturers can significantly improve overall efficiency and flexibility.

Tips: When selecting a contract manufacturer, consider their experience in your specific industry and their technological capabilities. Additionally, ensure their compliance with quality standards to avoid potential production issues. Establishing strong communication channels upfront can also facilitate smoother collaboration throughout the project.

When selecting top contract manufacturing companies, several key criteria should be considered to ensure that a partnership aligns with business objectives. First, it is essential to evaluate the company's overall industry experience and expertise. A firm with a proven track record in your specific sector can offer valuable insights and efficient solutions, thereby minimizing the risk of errors and production delays. Additionally, understanding their manufacturing capabilities, including technology utilization and production scale, can help in assessing whether they can meet your requirements—be it for high-volume production or specialized low-volume runs.

Another critical factor is compliance with quality standards and certifications, which indicate a commitment to maintaining consistent product quality. Companies that adhere to recognized industry benchmarks are more likely to produce reliable products, which is crucial for maintaining brand integrity. Furthermore, consider the level of communication and customer service the company provides. A responsive manufacturer that is willing to collaborate closely can facilitate smoother operations and adaptability to changes during the manufacturing process. Overall, these criteria help ensure a fruitful and efficient partnership in the realm of contract manufacturing.

The landscape of contract manufacturing is evolving rapidly, driven by the need for businesses to enhance efficiency while reducing costs. According to a report by Grand View Research, the global contract manufacturing market is projected to reach USD 258.24 billion by 2026, growing at a CAGR of 8.0% from 2019. This growth reflects the increasing reliance of companies across various sectors on outsourced manufacturing to streamline production and focus on core competencies.

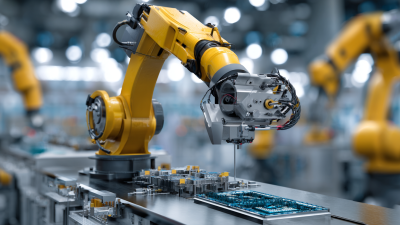

When examining top state contract manufacturing companies, several key players stand out due to their innovation and ability to adapt to market demands. Companies that excel in precision manufacturing and offer diverse services, including assembly, testing, and logistics, are crucial in supporting industries such as electronics, automotive, and pharmaceuticals. For instance, industry analyses reveal that companies leveraging automation and advanced technology are achieving significant operational efficiencies, which in turn enhances their competitiveness in the global market.

Furthermore, collaboration between manufacturers and their clients is becoming increasingly important. A study by Deloitte indicates that effective partnerships can lead to improved product quality and shorter time-to-market, addressing the fast-paced nature of consumer demand. As contract manufacturers continue to refine their processes and invest in new technologies, they will play an essential role in shaping the future of various industries, driving innovation and economic growth.

The landscape of contract manufacturing has evolved significantly, with companies across various states offering innovative solutions tailored to their clients’ specific needs. These firms leverage advanced technologies and processes to enhance efficiency and productivity, catering to diverse industries such as electronics, pharmaceuticals, and consumer goods. By emphasizing flexibility and scalability, they enable businesses to adapt quickly to market changes while maintaining high-quality standards.

In addition to traditional manufacturing services, many of these companies are at the forefront of integrating automation and smart manufacturing techniques. This includes the use of robotics and artificial intelligence, which streamline production lines and reduce operational costs. Moreover, sustainable manufacturing practices have gained traction, as firms are increasingly focusing on minimizing their environmental footprint through eco-friendly materials and energy-efficient processes. These innovative approaches not only improve the bottom line for clients but also align with growing consumer demand for sustainable products.

The state contract manufacturing sector is poised for significant growth, driven by evolving market needs and technological advancements. According to a recent report by the Freedonia Group, the U.S. contract manufacturing market is forecasted to grow at an impressive compound annual growth rate (CAGR) of 6.5% through the next five years. This growth is largely attributed to the increasing demand for specialized products, where companies seek out manufacturers that can provide tailored solutions without the overhead of in-house production facilities.

In addition to market growth, sustainability and automation are emerging as key trends shaping the future of contract manufacturing. A study by the National Institute of Standards and Technology reveals that 70% of manufacturers are investing in automation technologies to enhance productivity and efficiency. Simultaneously, many companies are adopting sustainable practices, which not only reduce their carbon footprint but also appeal to environmentally conscious consumers. As the industry adapts to these changes, we can expect a rise in partnerships between state manufacturers and technology providers, aiming to leverage innovative solutions that align with market demands while promoting sustainable manufacturing processes.