Welding fabrication plays a crucial role in a wide array of industries, from construction and automotive to aerospace and manufacturing. According to a 2021 report by the American Welding Society, the welding industry contributes over $30 billion to the U.S. economy and supports nearly 500,000 jobs, underscoring its significance in the global market. As projects become increasingly complex and demanding, mastering advanced welding fabrication techniques is essential for professionals looking to enhance efficiency, improve quality, and ensure safety on the job.

In an era where innovation is paramount, familiarity with the top welding fabrication techniques can separate excellent welders from the rest. Techniques such as MIG welding, TIG welding, and gas welding not only require skill but also a deep understanding of materials and methodologies. Additionally, as the demand for skilled welders rises—projected to grow by 8% from 2020 to 2030—the need to stay updated with the latest techniques has never been more critical. This article will explore the top ten welding fabrication techniques that can elevate the quality and durability of your projects, providing essential insights for both novice and experienced welders alike.

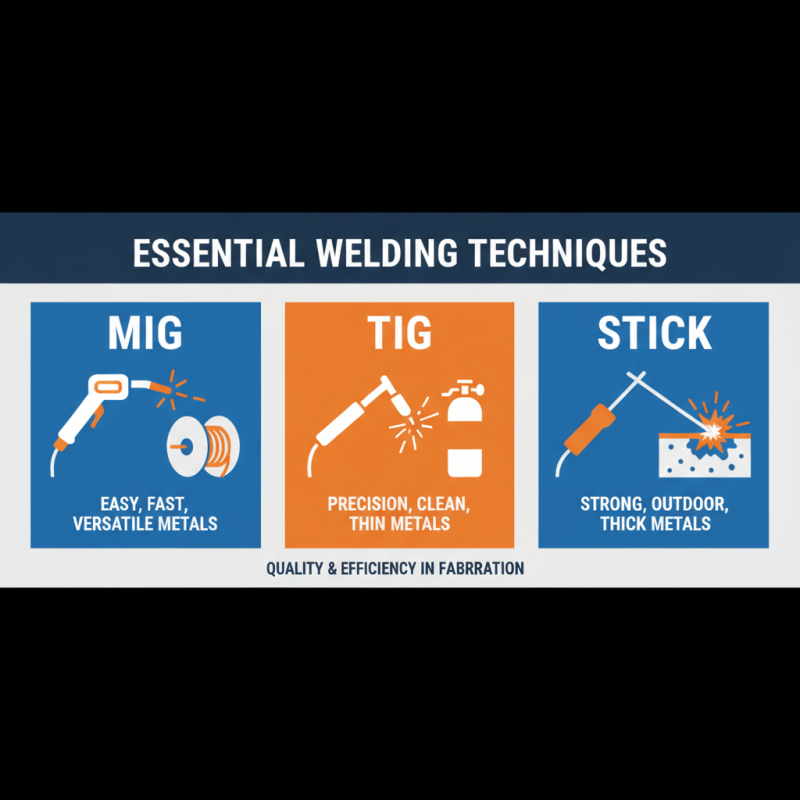

Welding is an essential skill in many fabrication projects, whether you're working on metal structures, artistic pieces, or practical components. Understanding various welding techniques can significantly impact the quality and efficiency of your work. Some popular methods include MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), and Stick welding, each offering unique advantages depending on the material and project requirements.

When choosing a welding technique, consider the material type and thickness. For thin metals, TIG welding is preferable due to its precision and control. Conversely, MIG welding proves effective for thicker materials, allowing for quicker welds with good penetration. Tip: Always practice on scrap material before tackling your main project to ensure you are comfortable with the welding process.

Another important factor in successful fabrication is the setup of your workspace. A clean, organized area will help you focus on the task at hand and prevent accidents. Maintain your equipment properly, ensuring that your welding tools are cleaned and in good condition to achieve the best results. Tip: Invest in proper safety gear, like gloves and goggles, and always follow safety protocols to protect yourself during welding operations.

MIG (Metal Inert Gas) welding, also known as Gas Metal Arc Welding (GMAW), has become one of the most widely used welding techniques in various fabrication projects. This method offers significant advantages in terms of speed and efficiency, making it ideal for production environments. According to the American Welding Society, MIG welding accounts for about 40% of the welding processes utilized in the industry today, highlighting its popularity among fabricators. The technique employs a continuous wire feed and a shielding gas to protect the weld pool from atmospheric contamination, resulting in clean and stable welds.

One of the key benefits of MIG welding is its versatility across a range of materials, including steel, aluminum, and stainless steel. This adaptability allows fabricators to tackle diverse projects, from automotive manufacturing to heavy equipment fabrication. Furthermore, industry reports indicate that MIG welding can significantly reduce labor costs and improve productivity, as it requires less operator skill compared to other methods, such as TIG welding. Studies have shown that skilled MIG welders can achieve welding speeds of up to 10-12 inches per minute, which can be crucial for meeting tight project timelines. With these compelling advantages, understanding MIG welding is essential for anyone looking to enhance their fabrication techniques and drive project success.

TIG welding, or Tungsten Inert Gas welding, stands out in the realm of welding fabrication techniques, particularly for projects requiring a high degree of precision and aesthetic appeal. This method employs a non-consumable tungsten electrode that produces a stable arc, allowing for controlled heat input. One of the primary advantages of TIG welding is its ability to weld thin materials and achieve clean, precise welds, making it ideal for applications in the automotive and aerospace industries, as well as for intricate artistic projects. The process also allows for the use of various filler materials, enabling welders to choose the best option for the specific metals being joined.

In addition to its technical advantages, TIG welding enhances the aesthetic quality of finished products. The technique produces a smooth and visually appealing weld bead, which is essential in artistic applications where appearance matters as much as functionality. Welders can manipulate the weld pool with exceptional control, tackling projects that require intricate designs or delicate components. This level of artistry in welding, combined with the reliability of TIG's low spatter and clean finishes, makes it a favored choice for those looking to create not just functional pieces but visually striking works of craftsmanship. Whether crafting custom metal sculptures or repairing specialized machinery, the role of TIG welding in ensuring both performance and beauty cannot be overstated.

This bar chart illustrates the suitability rating of various welding techniques, highlighting TIG welding as a leading method for precision and aesthetic projects. Understanding these techniques can enhance the quality and efficiency of your fabrication projects.

When it comes to welding fabrication techniques, two of the most commonly used methods are stick welding and flux-cored welding. Both techniques have distinct advantages and disadvantages, making them suitable for different applications and skill levels. Stick welding, or shielded metal arc welding (SMAW), involves using an electrode coated with flux that melts to create a protective gas shield during the welding process. This technique is well-known for its versatility and ability to perform well in outdoor conditions where wind could affect other types of welding.

On the other hand, flux-cored welding employs a tubular wire filled with flux, which also creates a protective shield. This method can be performed using a continuous feed setup, allowing for greater efficiency and speed, especially in thicker materials. One of the primary advantages of flux-cored welding is that it often requires minimal cleanup after the welding process due to the reduced amount of slag produced. However, it is generally more suited for thicker materials and may not be as effective in tight spaces compared to stick welding. Ultimately, the choice between stick and flux-cored welding will depend on the project requirements, skill level, and environmental factors relevant to the task at hand.

| Technique | Process Type | Material Suitability | Weld Appearance | Cost |

|---|---|---|---|---|

| Stick Welding | Shielded Metal Arc Welding (SMAW) | Steel, Stainless Steel, Cast Iron | Moderate | Low |

| Flux-Cored Welding | Flux-Cored Arc Welding (FCAW) | Steel, Some Non-Ferrous | Good | Moderate |

| MIG Welding | Gas Metal Arc Welding (GMAW) | Aluminum, Carbon Steel, Stainless Steel | Excellent | Moderate |

| TIG Welding | Gas Tungsten Arc Welding (GTAW) | Aluminum, Magnesium, Copper | Superior | High |

| Oxy-Acetylene Welding | Oxy-Fuel Welding (OFW) | Steel, Copper, Brass | Variable | Low |

| Plasma Arc Welding | Plasma Arc Welding (PAW) | Aluminum, Stainless Steel | Excellent | High |

| Electron Beam Welding | Electron Beam Welding (EBW) | Metals, Alloys | Excellent | Very High |

| Submerged Arc Welding | Submerged Arc Welding (SAW) | Carbon Steel, Low Alloy Steel | Very Good | Moderate |

| Stud Welding | Stud Welding | Carbon Steel, Stainless Steel | Excellent | Moderate |

| Friction Stir Welding | Friction Stir Welding (FSW) | Aluminum, Copper Alloys | Excellent | High |

Laser welding has emerged as a key technique in the metal fabrication industry, particularly for its efficiency in high-speed fabrication processes. By employing a highly focused laser beam, this technique allows for precise and rapid joining of materials, significantly reducing production time. According to a 2022 report by the International Institute of Welding, laser welding can increase production efficiency by up to 40% compared to traditional welding methods. This efficiency is particularly beneficial in sectors such as automotive and aerospace, where time-to-market is critical.

Moreover, the ability to weld thin materials with minimal heat input makes laser welding ideal for applications that require intricate designs and high-quality finishes. The precision of laser welding results in narrower heat-affected zones, which helps maintain the integrity of the base materials. A study published in the Journal of Materials Processing Technology highlighted that laser welding not only improves the mechanical properties of the welded joints but also reduces the likelihood of distortion and warping during the fabrication process. As industries continue to push for faster production rates without compromising quality, laser welding is set to play an increasingly vital role in modern fabrication techniques.

Welding fabrication is a crucial skill in various industrial and artistic projects, and understanding the top techniques can significantly enhance the quality and efficiency of work. Among the ten essential welding techniques, MIG welding stands out for its versatility and ease of use, making it ideal for most fabrication applications. TIG welding, on the other hand, excels in precision tasks, offering aesthetic benefits for intricate designs.

Additionally, comparing stick welding and flux-cored welding highlights their respective advantages in different environments and material types. For projects requiring speed and efficiency, laser welding becomes a valuable tool. It’s also imperative to prioritize safety and maintain quality control throughout the welding fabrication process, ensuring both successful outcomes and a secure work environment. Embracing these practices and techniques can lead to exceptional results in any welding fabrication endeavor.