In today's rapidly evolving manufacturing landscape, the significance of welding fabrication cannot be overstated. As industries strive for efficiency, quality, and innovation, welding fabrication emerges as a cornerstone of modern production techniques. This process not only ensures the structural integrity of various components but also paves the way for advanced designs and the integration of new materials. The advent of digital technologies has further transformed welding fabrication, enabling precision and automation that enhance productivity and reduce errors. By embracing these advancements, manufacturers can meet the increasing demands for customized solutions while optimizing resource utilization.

This article delves into the multifaceted role of welding fabrication in contemporary manufacturing, highlighting its essential contributions to sustainability, cost-effectiveness, and competitive advantage in a global marketplace.

Welding fabrication plays a pivotal role in enhancing manufacturing efficiency across various industries. According to a report from the American Welding Society, the welding sector contributes approximately $5 billion to the U.S. economy annually, underscoring its significance in manufacturing processes. By facilitating the joining of components with precision and strength, welding fabrication not only optimizes the production timeline but also reduces material waste, directly impacting the overall cost-effectiveness of manufacturing operations.

Moreover, advancements in welding technologies are driving efficiency improvements. For instance, the integration of automation in welding processes has been shown to increase productivity by 30% while maintaining high standards of quality control. A study from the International Institute of Welding indicates that automated welding not only speeds up fabrication times but also minimizes human error, resulting in less rework and higher customer satisfaction. As industries strive to meet rising demands for faster and more reliable manufacturing, the critical role of welding fabrication cannot be overstated, positioning it as a cornerstone of modern industrial efficiency.

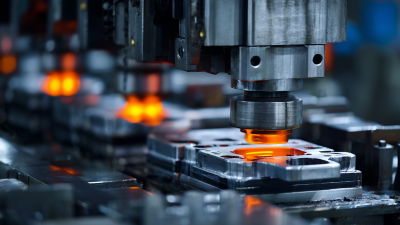

Innovative welding techniques are transforming modern industrial applications by enhancing efficiency and precision across various manufacturing sectors. Technologies such as laser welding, electron beam welding, and friction stir welding are pushing the boundaries of what is possible in welding fabrication. These methods offer significant advantages over traditional techniques, including reduced heat input, minimized distortion, and the ability to join dissimilar materials, which are becoming increasingly important in complex manufacturing environments.

Innovative welding techniques are transforming modern industrial applications by enhancing efficiency and precision across various manufacturing sectors. Technologies such as laser welding, electron beam welding, and friction stir welding are pushing the boundaries of what is possible in welding fabrication. These methods offer significant advantages over traditional techniques, including reduced heat input, minimized distortion, and the ability to join dissimilar materials, which are becoming increasingly important in complex manufacturing environments.

Moreover, automation and robotics are playing a crucial role in the evolution of welding processes. Robotic welding systems not only increase production speeds but also ensure consistent quality and repeatability. The integration of artificial intelligence into welding operations allows for real-time monitoring and adjustments, optimizing the welding parameters to achieve superior results. As industries continue to seek higher performance and sustainability, these innovative welding techniques will be vital in addressing the challenges of modern manufacturing, paving the way for advancements in product design and development.

The integration of robotics into welding fabrication has revolutionized modern manufacturing processes, providing a level of precision and efficiency that was previously unattainable. Through the utilization of robotic systems, manufacturers can achieve consistent weld quality, significantly reducing the likelihood of human error. Robots equipped with advanced sensors and algorithms can adjust parameters in real-time, ensuring optimal performance across various materials and welding techniques. This has not only enhanced productivity but also minimized material waste and operational costs.

Moreover, the use of robotics in welding fabrication allows for greater flexibility in production lines. Manufacturers can quickly reprogram robots to handle different tasks, enabling them to adapt to changing market demands without extensive downtime. This adaptability is crucial in an era where customization and rapid turnaround are key competitive advantages. Additionally, the application of robotics contributes to workplace safety by taking over dangerous tasks, allowing skilled operatives to focus on oversight and quality control rather than direct manual labor. As the manufacturing industry continues to evolve, the role of robotics in welding fabrication will undoubtedly be a game-changer, shaping the future of production.

Quality control in welding fabrication is pivotal to modern manufacturing processes, especially in sectors that require high structural integrity and safety, such as automotive and aerospace industries. According to the American Welding Society, non-conformance in welding can lead to operational failures, safety hazards, and significant financial losses. Implementing rigorous quality control measures, such as in-process inspections and non-destructive testing (NDT), ensures that welds meet specified standards and performance benchmarks.

Moreover, the integration of advanced technologies, such as AI-driven visual inspection systems, has revolutionized quality assurance in welding fabrication. A recent study highlighted that the use of these systems can improve defect detection rates by up to 30%, significantly enhancing overall weld quality. In the automotive sector, where the quality of welds directly influences vehicle safety and performance, robust control measures are crucial for compliance with safety regulations and consumer expectations. By prioritizing quality control in welding processes, manufacturers not only ensure product reliability but also reinforce their commitment to maintaining the highest safety standards in their operations.

The evolving landscape of manufacturing has brought forth a strong emphasis on welding fabrication, particularly as industries face challenges like labor shortages and supply chain disruptions. As companies transition towards flexible manufacturing systems, the integration of advanced welding technologies becomes essential. Industrial welding robotics, including arc and laser welding robots, are increasingly being adopted to enhance precision and efficiency. This shift not only meets the growing demand for customized welding solutions in sectors like aerospace and automotive but also alleviates some of the workforce shortages by automating repetitive tasks.

Future trends indicate a heightened focus on smart welding solutions that leverage artificial intelligence and machine learning. Innovations in interactive capabilities for robotic welding systems are paving the way for more adaptable and efficient production processes. The rise of sophisticated equipment, capable of real-time adjustments based on operational feedback, is set to redefine standard practices in industrial welding fabrication. As manufacturers embrace these new technologies, welding will evolve from traditional methods into a pivotal component of smart manufacturing, addressing the diverse and dynamic needs of the market.