In the ever-evolving landscape of industry, machine fabrication techniques play a crucial role in driving success. As we approach 2026, businesses must adapt to new technologies and methods. Machine fabrication is not merely about efficiency; it encompasses precision and quality. Companies that embrace innovative techniques will stand out.

Today’s market demands flexibility. Machine fabrication processes must align with the unique needs of various industries. For instance, advanced robotics and automation are becoming essential. They improve accuracy while minimizing waste. However, not all businesses are equipped to implement these changes effectively. Many struggle to balance speed and craftsmanship.

Reflection is vital in this journey. How can companies improve their machine fabrication processes? Identifying weaknesses is the first step. Embracing new tools and methodologies is essential, yet challenging. The path to success is not always clear. It requires constant learning and adaptation. In the end, the right machine fabrication techniques could define a company’s future.

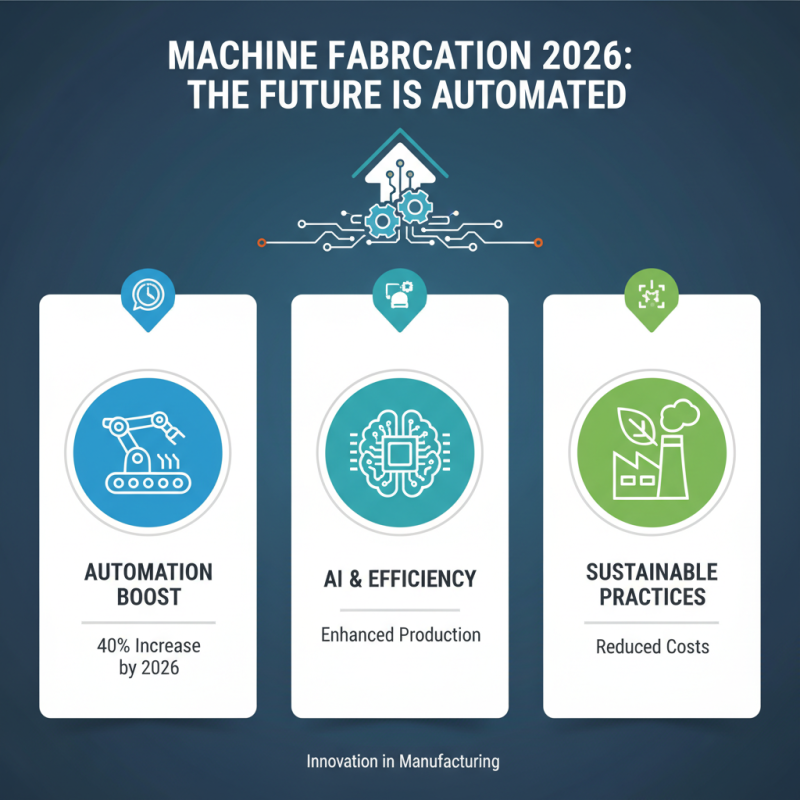

The future of machine fabrication in 2026 is poised for exciting advancements. Emerging trends focus on automation, artificial intelligence, and sustainable practices. Reports indicate a projected 40% increase in automated fabrication methods by 2026. This shift aims to enhance efficiency and reduce manufacturing costs.

Tips for industry players: invest in training for your staff. Familiarity with new technologies is vital. Data from recent studies show that companies adopting AI-driven solutions experience a 20% boost in productivity. However, not all businesses are ready for such changes. Some struggle with integrating new tech into their existing workflows.

Another key trend is the use of eco-friendly materials. About 30% of manufacturers are now prioritizing sustainability. This move is essential for long-term success. But it requires careful planning. Businesses must assess their supply chains to avoid potential pitfalls. Balancing innovation with sustainability is a challenge that needs ongoing attention and adjustment.

In evaluating machine fabrication techniques, key metrics play a vital role. Metrics such as

production efficiency, material utilization, and cost-effectiveness directly influence operational success.

A recent industry report highlights that companies optimizing these metrics can reduce their manufacturing costs by up to 25%.

This underscores the need for continuous evaluation.

To gauge success effectively, focus on real-time data collection.

Monitor equipment performance closely. An unexpected machine breakdown can halt production for hours. Regular audits reveal flaws in existing processes, allowing for timely adjustments.

Collecting feedback from machine operators can lead to critical insights that data alone might miss.

Tips: Streamline communication between teams. Ensure everyone understands the manufacturing objectives.

Regular training can enhance skill levels. Remain open to experimenting with new techniques. Not every approach will yield immediate results, but innovation often leads to breakthroughs.

Always seek opportunities for improvement, even in successful areas.

Automation has transformed machine fabrication processes, significantly enhancing efficiency. By incorporating robotics and AI, businesses can streamline operations. This reduction in manual labor speeds up production cycles. However, automation may lead to job displacement, which raises concerns. Balancing technology and human resources is crucial for sustainable growth.

In 2026, sustainability practices in machine fabrication are more important than ever. Industries are seeking greener methods to reduce their environmental footprint. One notable trend is the use of recyclable materials. Companies are now opting for metals and composites that have a lower impact on nature. These choices help in cutting waste and improving efficiency.

However, the shift towards sustainability isn't without challenges. Many companies still rely on traditional methods. They often face pressure to meet production demands quickly, leading to environmentally harmful practices. For instance, some still use hazardous materials in their processes. This raises questions about long-term impacts on health and the environment.

Education plays a crucial role in this transition. Many workers lack awareness of sustainable techniques. Training programs can bridge this gap, fostering a culture of innovation. By encouraging employees to think critically about their work processes, companies can unlock new solutions. A commitment to sustainability isn't just about compliance; it’s about reimagining the entire fabrication system for a better future.

The landscape of fabrication is evolving rapidly. Traditional methods, like welding and machining, have been the industry standard for decades. However, their limitations in precision and speed have prompted many to explore modern alternatives. According to a report by the International Journal of Advanced Manufacturing Technology, traditional techniques can take up to 30% longer when working on complex components.

Modern fabrication methods, such as additive manufacturing and laser cutting, are gaining traction. These techniques can reduce waste and increase precision significantly. For instance, research shows that 3D printing can reduce material waste by up to 90%. This is a game-changer for industries focused on sustainability. Yet, transitioning to these advanced methods poses challenges. Training workers and integrating new technology can be costly and time-consuming.

Despite the clear advantages of modern techniques, not every company is ready for a full shift. Some industries still heavily rely on traditional practices due to familiarity and established workflows. A survey by the Manufacturing Industry Association indicated that 47% of firms view traditional methods as more reliable. This hesitance highlights the ongoing debate within the industry. Balancing innovation with reliability is crucial for long-term success.