Welding fabrication plays a vital role in modern manufacturing. It combines engineering and artistry, creating essential structures and parts. From automobiles to aircraft, welding fabrication is everywhere. It enhances strength and durability in products we rely on daily.

However, welding fabrication isn't without its challenges. Safety is a major concern. Mistakes can lead to serious accidents. Also, the skills required are highly specialized. Not everyone can weld effectively. This can create a gap in the workforce.

Moreover, the tools and materials can be expensive. Companies often struggle with budget constraints. Balancing quality with cost is tricky. Despite these challenges, the importance of welding fabrication cannot be understated. It is integral to innovation and efficiency in manufacturing today.

Welding fabrication plays a crucial role in modern manufacturing. It enhances structural integrity in various applications. This process involves joining materials through heat and pressure. As a result, components become stronger and more reliable.

When welding techniques are properly applied, objects can withstand significant stress. Factories rely on welded structures to create everything from bridges to machinery. However, not all welds are created equal. Quality can vary based on the skill of the welder and the conditions of the workspace.

Sometimes, welds may not bond as intended. This can lead to failures that compromise the entire structure. Monitoring and inspection are vital to ensure safety. Each weld requires careful planning and execution. A small mistake can have serious ramifications. Hence, continuous training and development in welding techniques are essential for maintaining high standards in manufacturing.

Welding fabrication plays a vital role in the global manufacturing landscape. Statistics reveal that welding contributes significantly to various industries. For instance, it's critical in aerospace, automotive, and construction sectors. Reports estimate that welders create millions of jobs worldwide, emphasizing its importance in economic growth.

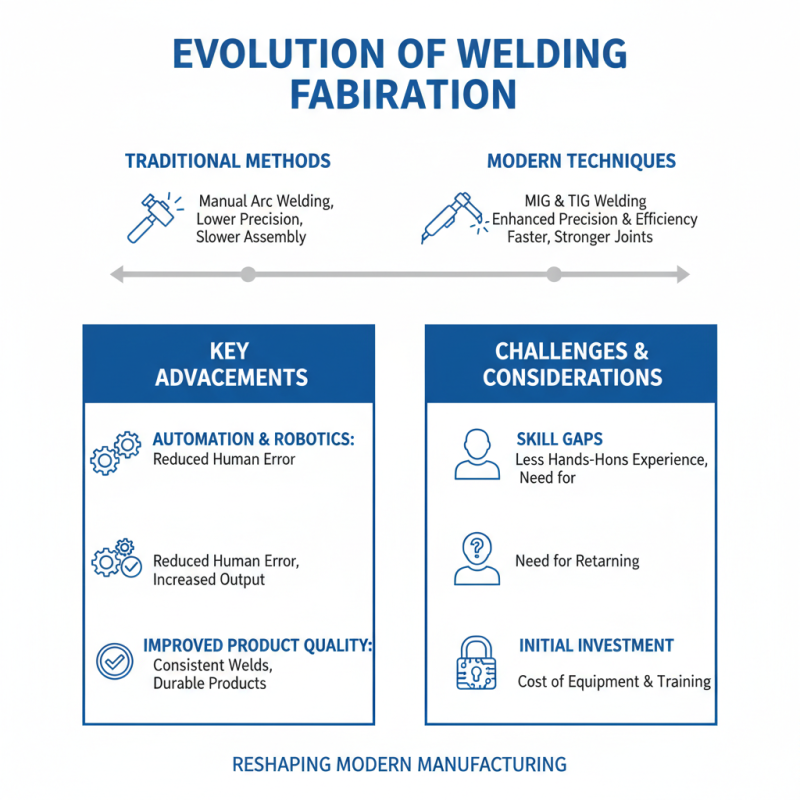

In recent years, the demand for skilled welders has surged. As industries evolve, the skills required in welding fabrication must also adapt. However, there is a noticeable skills gap. Many regions struggle to find qualified individuals to meet increasing industry demands. This discrepancy invites reflection on training programs and educational resources.

Moreover, welding's environmental impact demands attention. While it enables substantial production, it often generates harmful emissions. The sector must invest in more sustainable practices. Innovations in technology could help reduce weld-related waste. Balancing production efficiency with environmental responsibility remains a challenge for manufacturers today.

| Aspect | Value |

|---|---|

| Global Welding Market Size (2023) | $22 Billion |

| Growth Rate (2023-2030) | 4.5% CAGR |

| Percentage of Manufacturing Microfabrication Related to Welding | 35% |

| Number of Welders Worldwide | 2.5 Million |

| Welding's Contribution to Construction Industry | 50% of Total Fabrication |

| Average Salary of Welders in the U.S. | $45,000 per year |

| Applications of Welding in Manufacturing | Automotive, Aerospace, Shipbuilding, Construction |

Welding fabrication has evolved significantly, bringing forth advancements that reshape modern manufacturing. Techniques like MIG and TIG welding have improved precision and efficiency. These methods enable faster assembly and stronger joints, enhancing product quality. Automation integrates seamlessly into welding processes, reducing human error and increasing output. However, reliance on automation can lead to skill gaps among workers.

Training is crucial in this evolving landscape. As machines take over basic tasks, workers must adapt to more complex roles. Older employees may struggle with new technologies, creating challenges in workforce dynamics. Continuous education is essential to maintain high productivity levels. The balance between technology and skilled labor remains a point of reflection for companies.

Moreover, advancements in materials science have introduced new alloys and composites. These materials require unique welding techniques, pushing the boundaries of traditional methods. While this innovation drives productivity, it also presents a learning curve. Companies must invest time and resources to master these techniques. The journey of embracing these changes can be daunting yet rewarding, highlighting the complex nature of modern manufacturing.

Welding fabrication plays a crucial role in manufacturing. It offers remarkable cost-effectiveness compared to other methods. By fusing materials together, manufacturers reduce the need for additional components. This leads to fewer parts to manage and a streamlined production process.

Consider the energy savings. Welding often consumes less energy than machining or assembly. This not only cuts costs but also minimizes the environmental impact. However, the initial investment in skilled labor and equipment can be substantial. Many companies hesitate to dive into welding projects due to these costs.

Yet, the benefits can outweigh the risks. A well-executed welding process can enhance durability and quality. Consider steel structures; when welded correctly, they can withstand years of stress. However, poor welding can lead to failures, costing companies significantly. Hence, continuous training and quality checks are necessary to mitigate these risks.

Welding fabrication plays a vital role in modern manufacturing. However, the environmental impact of welding practices cannot be overlooked. Traditional welding methods often produce harmful fumes and waste. This pollution can affect both workers and nearby communities.

Sustainable welding practices are emerging in response to these concerns. Many manufacturers are exploring eco-friendly techniques. These methods include low-emission welding processes and recycling welding materials. Additionally, using renewable energy sources during fabrication can further reduce carbon footprints.

Yet, challenges remain. Not all manufacturers prioritize sustainability. Transitioning to greener practices may involve higher upfront costs. Moreover, not every welding technique offers easy alternatives. The industry must reflect on these issues. Balancing productivity and environmental responsibility is crucial. Through collaboration and innovation, the future of welding fabrication can be more sustainable.